In short, PVD plating is exceptionally durable. It creates a surface finish that is significantly harder and more resistant to wear, corrosion, and scratches than traditional plating methods or raw metals. For many applications, a PVD coating will retain its original appearance for years, often outlasting the useful life of the product itself.

The true measure of PVD's durability isn't just its impressive hardness, but how that hardness is matched to the coating's thickness and the underlying material. When these factors are correctly specified for the intended use, PVD provides one of the most resilient finishes available.

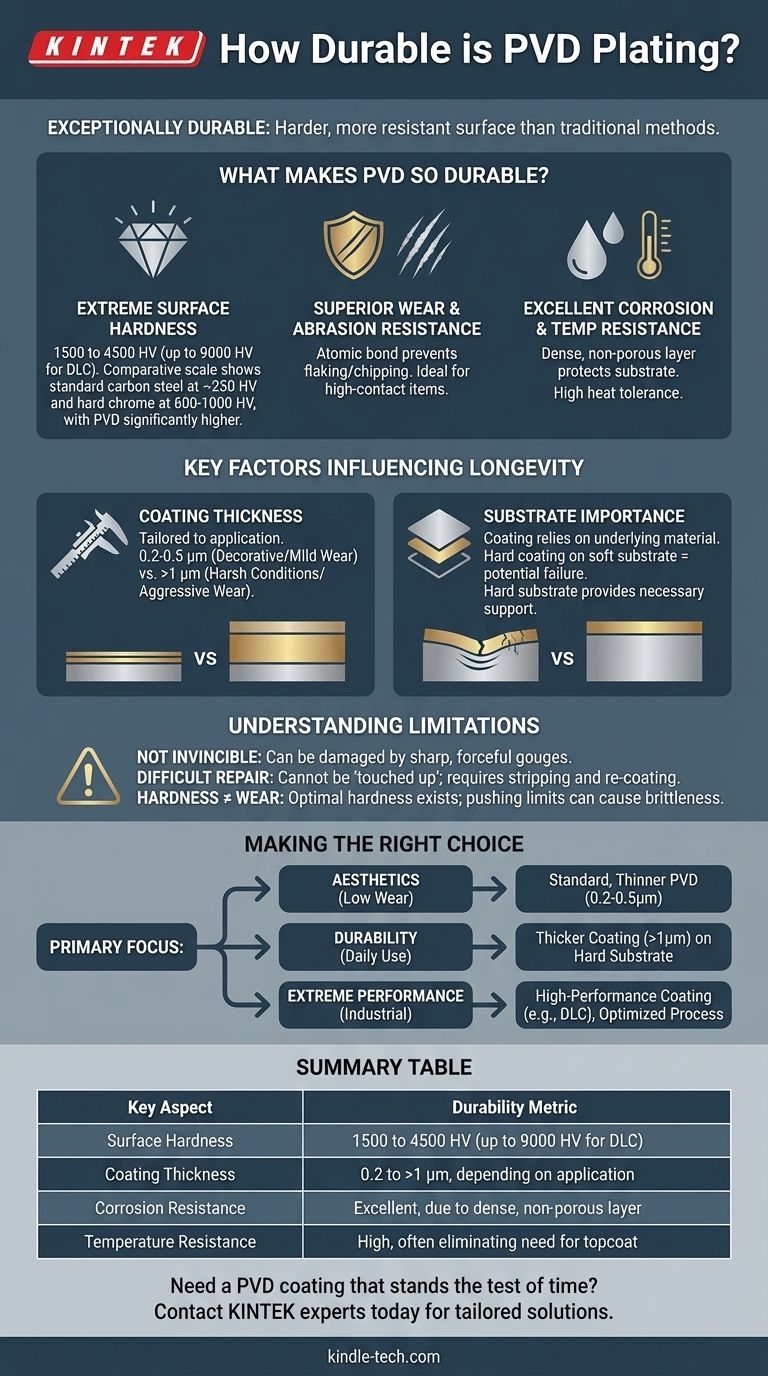

What Makes PVD So Durable?

Physical Vapor Deposition (PVD) is not a simple coating; it's a process that bonds a thin film of metal or ceramic to a substrate at an atomic level. This fundamental difference is the source of its superior performance.

Extreme Surface Hardness

PVD coatings are remarkably hard. Their hardness is typically measured on the Vickers scale (HV), where a higher number indicates greater hardness.

A PVD finish generally falls between 1500 to 4500 HV. Certain advanced materials like Diamond-Like Carbon (DLC) can reach up to 9000 HV.

To put this in perspective, common carbon steels have a hardness of around 250 HV, while hard chrome plating is in the 600 to 1000 HV range. This means a standard PVD coating is several times harder than even chrome.

Superior Wear & Abrasion Resistance

This extreme hardness directly translates to exceptional resistance against daily wear and tear. The strong bond prevents the coating from flaking or chipping like a layer of paint.

This is why PVD is trusted for high-contact items like watch cases, bands, and premium faucets, which maintain their look even after years of exposure to sweat, moisture, and daily friction.

Excellent Corrosion & Temperature Resistance

The PVD process creates a very dense and non-porous layer. This shield protects the underlying material (the substrate) from exposure to oxygen, moisture, and other corrosive elements.

Because of this, PVD-coated items are highly resistant to tarnishing and corrosion. The process also gives the surface high-temperature resistance, often eliminating the need for a protective topcoat.

Not All PVD is Created Equal: Key Factors Influencing Longevity

While PVD is inherently durable, its ultimate performance depends on several critical variables. Simply asking for "PVD" is not enough; the specification matters.

The Role of Coating Thickness

The thickness of the coating is tailored to the application. For decorative items with mild wear, a thin coating of 0.2 to 0.5 micrometers (μm) is often sufficient to last for many years.

For products subject to harsher conditions and more aggressive wear, a thicker coating (typically greater than 1μm) is required to provide long-term durability.

The Importance of the Substrate

A PVD coating is only as strong as its foundation. The coating itself is very thin, so it relies on the hardness of the underlying material for support.

Applying a very hard PVD coating to a soft substrate is a recipe for failure. A significant impact could dent the soft material underneath, causing the rigid coating to fracture. A hard substrate provides the support needed to prevent this.

Understanding the Trade-offs and Limitations

No finish is indestructible. Being aware of PVD's limitations is key to using it effectively and avoiding disappointment.

It Is Not Invincible

While highly resistant to scratches and wear, PVD coatings can be damaged by aggressive attacks. A sharp, forceful gouge from a hard object can still penetrate the finish.

Repair Can Be Difficult or Impossible

PVD is an industrial vacuum deposition process. It cannot be "touched up" like paint. If a PVD finish is significantly damaged, the only solution is often to chemically strip the entire object and re-coat it from scratch.

Hardness and Wear Are Not the Same

While related, maximum hardness does not always equal maximum wear resistance. There is an optimal hardness for any given PVD material. Pushing hardness beyond this point can sometimes indicate an improper structure, which could make the coating more brittle.

Making the Right Choice for Your Application

Selecting the right PVD specification is about matching the finish to the product's intended life and environment.

- If your primary focus is aesthetics for a low-wear item (e.g., decorative hardware, jewelry): A standard, thinner PVD coating (0.2-0.5μm) will provide years of color stability and tarnish resistance.

- If your primary focus is durability for a daily-use item (e.g., watches, high-end faucets): A thicker coating (>1μm) on a hard substrate like stainless steel is necessary to withstand scratches and constant contact.

- If your primary focus is extreme performance (e.g., industrial tools, engine components): You must specify a high-performance coating like DLC and ensure the substrate and process are optimized for maximum resilience.

By understanding these factors, you can confidently specify a PVD finish that delivers the exact level of durability your project demands.

Summary Table:

| Key Aspect | Durability Metric |

|---|---|

| Surface Hardness | 1500 to 4500 HV (up to 9000 HV for DLC) |

| Coating Thickness | 0.2 to >1 μm, depending on application |

| Corrosion Resistance | Excellent, due to dense, non-porous layer |

| Temperature Resistance | High, often eliminating need for topcoat |

Need a PVD coating that stands the test of time? At KINTEK, we specialize in lab equipment and consumables, including PVD solutions tailored to your specific durability requirements. Whether you're developing consumer goods, industrial tools, or precision components, our expertise ensures your products achieve maximum resilience and longevity. Contact our experts today to discuss how we can enhance your project's performance!

Visual Guide

Related Products

- Vacuum Hot Press Furnace Machine for Lamination and Heating

- HFCVD Machine System Equipment for Drawing Die Nano-Diamond Coating

- 915MHz MPCVD Diamond Machine Microwave Plasma Chemical Vapor Deposition System Reactor

- Laboratory Sterilizer Lab Autoclave Pulse Vacuum Lifting Sterilizer

- CVD Diamond Cutting Tool Blanks for Precision Machining

People Also Ask

- What are the advantages and disadvantages of hot stamping? Unlock Ultra-High Strength for Automotive Parts

- What is hot press moulding? Achieve Superior Density and Complex Shapes with Heat and Pressure

- What is the purpose of laminating? Protect and Enhance Your Documents for Long-Term Use

- What is hot press forging? Creating Complex, High-Strength Metal Components

- How does hot pressing work? Achieve Maximum Density for Advanced Materials