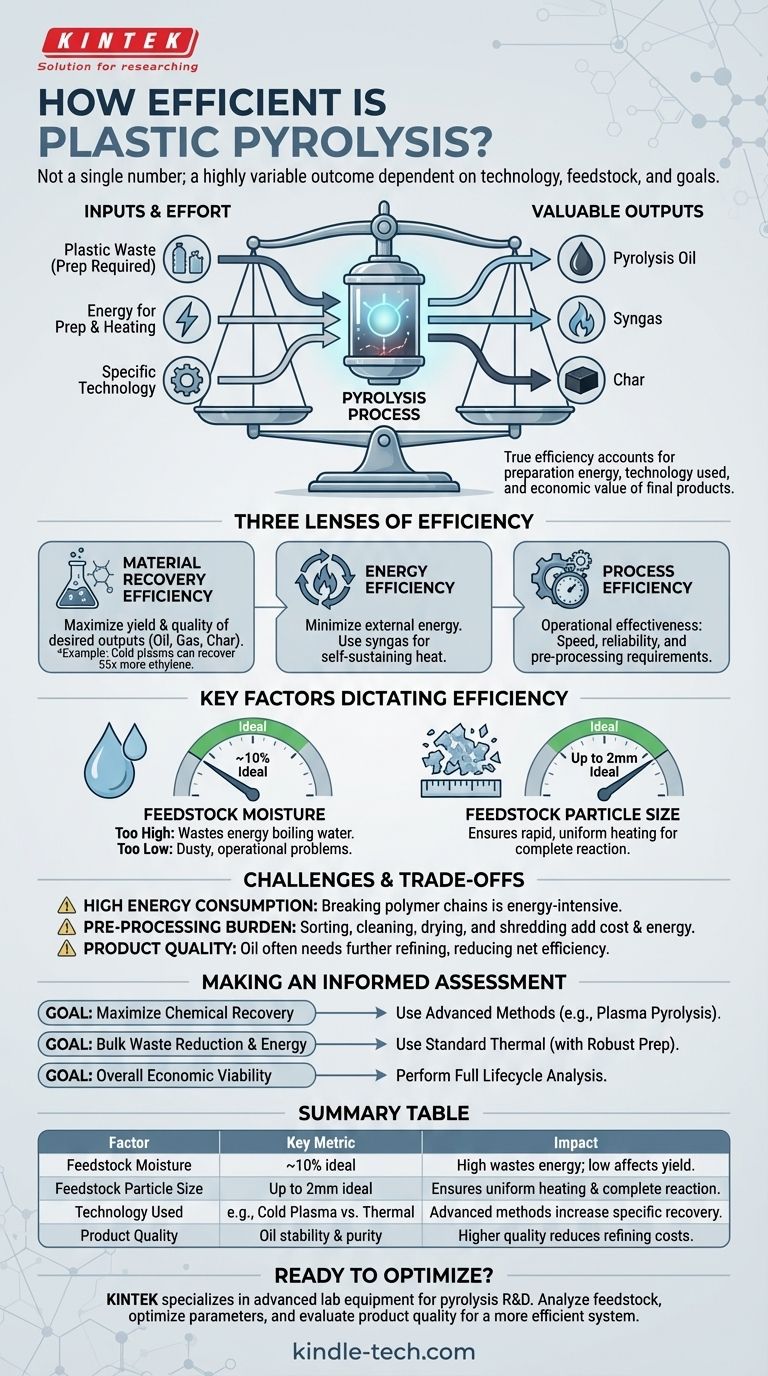

The efficiency of plastic pyrolysis is not a single number; it is a highly variable outcome that depends heavily on the specific technology used, the quality and preparation of the plastic feedstock, and what you are trying to produce. While some advanced methods show remarkable results for specific outputs, the overall energy and material efficiency is determined by a complex interplay of factors.

The true measure of pyrolysis efficiency goes beyond a simple energy-in vs. energy-out calculation. It must account for the energy spent preparing the plastic waste, the specific technology employed, and the economic value of the final recovered products—oil, gas, and char.

Deconstructing Pyrolysis Efficiency

To understand the efficiency of any given system, we must first define what we are measuring. In the context of plastic pyrolysis, efficiency can be viewed through three distinct lenses.

Material Recovery Efficiency

This metric focuses on the conversion of plastic waste into valuable products. The goal is to maximize the yield and quality of the desired outputs, whether that's liquid oil (pyrolysis oil), combustible gases (syngas), or solid residue (char).

The technology used has a massive impact here. For example, cold plasma pyrolysis can recover 55 times more ethylene—a valuable chemical building block—compared to standard thermal pyrolysis. This represents a huge leap in material-specific efficiency.

Energy Efficiency

This is the classic energy balance. Pyrolysis is an energy-intensive process that requires heating materials to high temperatures in an oxygen-free environment.

An energy-efficient system is one that minimizes the external energy required to run the process. Often, the syngas produced during pyrolysis is captured and burned to provide the heat needed, creating a more self-sustaining and efficient operation.

Process Efficiency

This refers to the operational effectiveness of the system. It encompasses the speed of the reaction, the reliability of the equipment, and the amount of pre-processing required to make the feedstock suitable for the reactor.

Optimizing process efficiency is key to making a pyrolysis plant economically viable and scalable.

Key Factors That Dictate Efficiency

The theoretical potential of a pyrolysis technology can only be realized if the operating conditions are precisely controlled. Several factors are critical.

Feedstock Moisture Content

The amount of water in the plastic waste is a crucial variable. The ideal moisture content is around 10%.

If the moisture is too high, the process wastes significant energy boiling off the excess water instead of breaking down the plastic. If it's too low, the feedstock can become dusty, which can create operational problems and may negatively affect oil production.

Feedstock Particle Size

Pyrolysis relies on rapid and uniform heat transfer throughout the feedstock. To achieve this, most technologies require very small particle sizes, often up to just 2 mm.

Larger particles heat unevenly, leading to an incomplete reaction. This results in lower quality oil and a less efficient conversion of waste into valuable products.

The Pyrolysis Technology Used

As mentioned, the choice of technology is fundamental. Traditional thermal pyrolysis is a mature process, but newer innovations are changing the efficiency landscape.

Methods like cold plasma pyrolysis demonstrate that targeting the recovery of specific high-value chemicals can yield far greater efficiency and economic returns than simply producing a generic fuel oil.

Understanding the Trade-offs and Challenges

An objective assessment requires acknowledging the inherent challenges that impact the real-world efficiency of plastic pyrolysis.

High Energy Consumption

No matter the method, breaking down long polymer chains is an energy-intensive thermochemical process. The initial energy investment to bring the reactor to operating temperature is significant.

The Burden of Pre-Processing

The strict requirements for moisture and particle size mean that plastic waste cannot simply be dumped into a reactor. It must be sorted, cleaned, dried, and shredded.

This pre-processing stage consumes additional energy and capital, which must be factored into any calculation of overall system efficiency.

Quality of the Final Products

The "pyrolysis oil" produced is not equivalent to crude oil. It is often acidic, unstable, and contains contaminants that must be removed through further refining before it can be used as a fuel or chemical feedstock. Each additional step reduces the net energy and economic efficiency of the entire process.

Making an Informed Assessment

To determine if pyrolysis is an efficient solution, you must align the technology and process with your primary objective.

- If your primary focus is maximizing valuable chemical recovery: Investigate advanced methods like plasma pyrolysis that are designed to break plastics back down into their original monomer building blocks.

- If your primary focus is bulk waste reduction and energy generation: A standard thermal pyrolysis plant can be effective, provided you have a robust system for preparing feedstock to precise specifications.

- If your primary focus is overall economic viability: You must perform a full lifecycle analysis that includes the cost of waste acquisition and preparation against the fluctuating market value of the refined end-products.

Ultimately, the efficiency of plastic pyrolysis is not an inherent property of the process itself, but a direct result of a carefully engineered and rigorously controlled system.

Summary Table:

| Factor | Key Metric | Impact on Efficiency |

|---|---|---|

| Feedstock Moisture | ~10% ideal | High moisture wastes energy; too low can affect oil yield. |

| Feedstock Particle Size | Up to 2mm ideal | Ensures uniform heating and complete reaction. |

| Technology Used | e.g., Cold Plasma vs. Thermal | Advanced methods can drastically increase specific chemical recovery. |

| Product Quality | Oil stability & purity | Higher quality reduces need for costly further refining. |

Ready to Optimize Your Pyrolysis Process?

Understanding the complexities of pyrolysis efficiency is the first step. The next is implementing the right technology and processes for your specific goals, whether that's bulk waste reduction or high-value chemical recovery.

KINTEK specializes in advanced laboratory equipment and consumables for pyrolysis research and development. We provide the precise tools needed to analyze feedstock, optimize reaction parameters, and evaluate product quality, helping you build a more efficient and economically viable waste conversion system.

Let our expertise help you:

- Select the right analytical equipment for feedstock and product characterization.

- Optimize pre-processing parameters like moisture content and particle size.

- Accurately assess the efficiency and economic potential of your pyrolysis process.

Contact us today to discuss how KINTEK's solutions can enhance your pyrolysis research and move your project toward greater efficiency and success.

Visual Guide

Related Products

- Customizable Laboratory High Temperature High Pressure Reactors for Diverse Scientific Applications

- Desktop Fast Laboratory Autoclave Sterilizer 35L 50L 90L for Lab Use

- High Temperature Constant Temperature Heating Circulator Water Bath Chiller Circulator for Reaction Bath

- Wall Mounted Water Distillation Unit

- High Energy Planetary Ball Mill Machine for Laboratory Horizontal Tank Type

People Also Ask

- Why are high-precision pressure sensors and temperature control systems critical for hydrothermal reaction equilibrium?

- What is the function of a PTFE-lined hydrothermal autoclave in cys-CDs synthesis? Achieve High-Purity Carbon Dots

- Why use high-pressure reactors for food waste pretreatment? Boost Hydrogen Production Efficiency Today!

- Why are high-strength alloy tube reactors critical for HHIP? Ensuring Safety and Purity in High-Pressure Environments

- What role does a high-pressure reactor play in the hydrodeoxygenation (HDO) of bio-oil? Drive Deep Fuel Upgrading