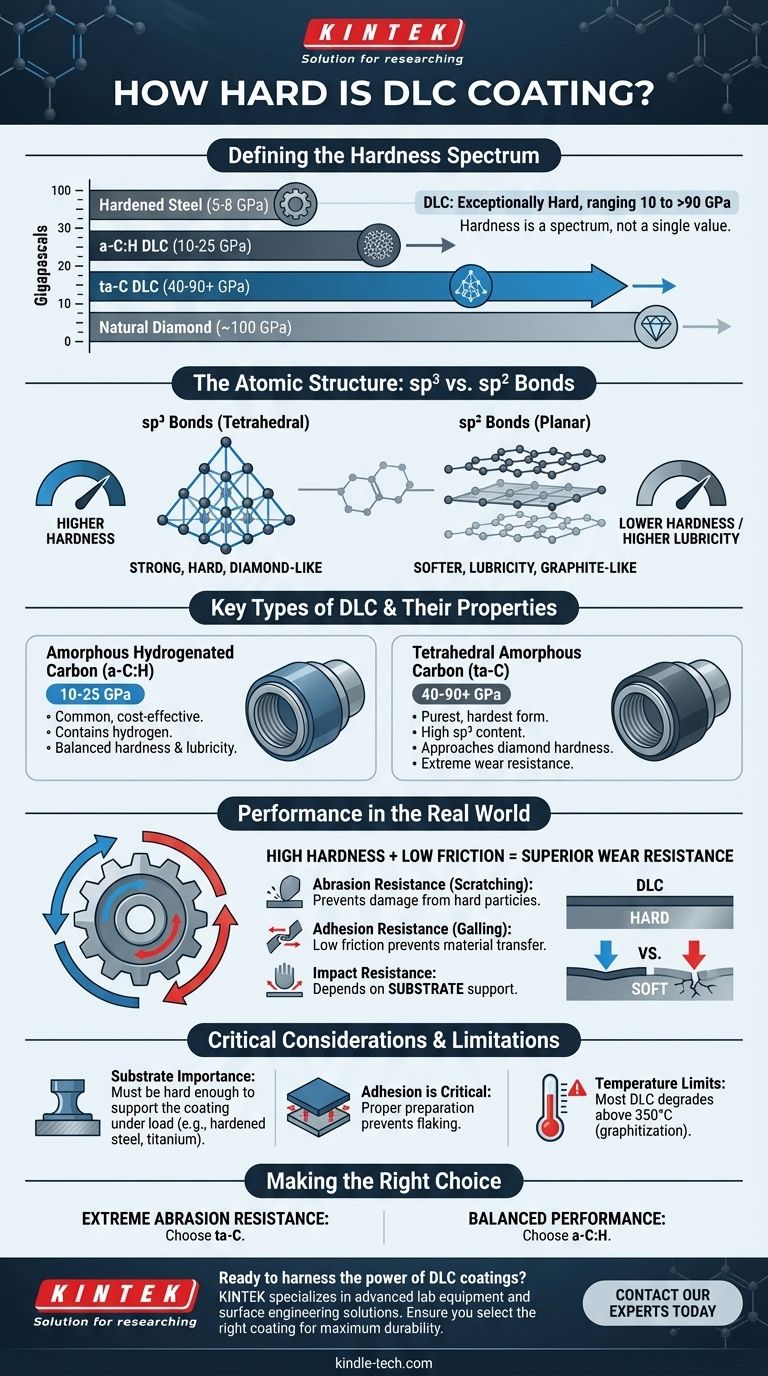

When evaluating surface treatments, the hardness of a Diamond-Like Carbon (DLC) coating is one of its most defining features. DLC is exceptionally hard, with values ranging from 10 Gigapascals (GPa) to over 90 GPa depending on the specific type. For comparison, most hardened steels fall between 5-8 GPa, while natural diamond, the hardest known material, is around 100 GPa.

The term "DLC" describes a family of coatings, not a single material. Its hardness is a spectrum, dictated by the atomic structure of the specific coating. The true value of DLC emerges not just from its hardness, but from its unique combination of hardness and low friction, which together create superior wear resistance.

What "Hardness" Means for DLC Coatings

Understanding the hardness of DLC requires looking beyond a single number. The specific atomic structure of the coating is what determines its physical properties and, ultimately, its performance in a given application.

Beyond a Single Number

Hardness is a measure of a material's resistance to localized plastic deformation, such as a scratch or indentation. While often simplified to a single value, it's measured on various scales like Vickers (HV) or Mohs. For advanced materials like DLC, scientists often use Gigapascals (GPa) to measure the indentation pressure it can withstand.

The Role of Atomic Bonds

DLC is an amorphous material, meaning its atoms lack the long-range crystalline order of a true diamond. Its properties are defined by the ratio of two types of carbon-to-carbon bonds:

- sp³ bonds: The strong, tetrahedral bonds that give diamond its extreme hardness.

- sp² bonds: The planar bonds found in graphite, which are softer and provide lubricity.

A higher percentage of sp³ bonds results in a harder, more "diamond-like" coating.

Key Types of DLC and Their Hardness

The sp³/sp² ratio varies across different types of DLC, creating a range of properties.

- Amorphous Hydrogenated Carbon (a-C:H): This is a very common and cost-effective form of DLC. It contains hydrogen, which helps stabilize the amorphous structure. Its hardness typically ranges from 10 to 25 GPa.

- Tetrahedral Amorphous Carbon (ta-C): This is the purest and hardest form of DLC, containing almost no hydrogen and a very high percentage (up to 85%) of sp³ bonds. Its hardness can range from 40 to over 90 GPa, approaching that of natural diamond.

How Hardness Translates to Real-World Performance

A high hardness value is only part of the story. The practical durability of a DLC-coated component depends on how its properties work together.

High Hardness + Low Friction = Superior Wear Resistance

This is the defining advantage of DLC. While high hardness provides excellent resistance to abrasive wear (scratching), its extremely low coefficient of friction (lubricity) prevents adhesive wear (galling and material transfer). This combination allows moving parts to slide against each other with minimal degradation.

Impact Resistance vs. Hardness

Extremely hard materials can also be brittle. A DLC coating is a very thin layer, typically only 1 to 5 microns thick. Its ability to resist impact depends heavily on the substrate—the material it is coated onto. A hard, thin coating on a soft material can crack or delaminate under sharp impact because the underlying material deforms too easily.

The Importance of the Substrate

For the DLC coating to be effective, the component it is applied to must be hard enough to support the coating under load. This is why DLC is most effective on hardened steels, titanium alloys, or other robust materials. It enhances a good surface; it cannot salvage a poor one.

Understanding the Trade-offs and Limitations

While powerful, DLC is not a universal solution. Its effectiveness is contingent on the specific type, application process, and operational environment.

Not All DLC is Created Equal

The term "DLC" is used broadly in marketing. A low-cost coating from an unreliable vendor may have a poor bond structure, leading to flaking, or a low sp³ content, resulting in disappointing hardness. The quality and consistency of the deposition process are critical.

Adhesion is Critical

Even the hardest coating is useless if it doesn't stick to the part. Proper surface preparation and the use of intermediate bonding layers are essential to ensure the DLC coating has strong adhesion to the substrate, preventing it from chipping or peeling away under stress.

Temperature Limitations

Most DLC coatings, particularly those containing hydrogen, begin to break down at elevated temperatures (typically above 350°C / 660°F). At these temperatures, the hard sp³ bonds can convert to softer sp² bonds (graphitization), causing the coating to lose its hardness and protective qualities.

Making the Right Choice for Your Application

Selecting the right surface treatment requires matching the coating's properties to the demands of the environment.

- If your primary focus is extreme scratch and abrasion resistance: Seek out non-hydrogenated tetrahedral amorphous carbon (ta-C) coatings, which offer the highest possible hardness.

- If your primary focus is balanced performance for sliding components: A standard hydrogenated amorphous carbon (a-C:H) provides an excellent combination of high hardness and low friction for a wide range of parts.

- If your application involves high temperatures or extreme loads: You must verify the specific DLC's thermal stability and ensure the substrate material is sufficiently hard to support the coating.

By understanding that DLC's true value lies in the specific type and its interplay of hardness and lubricity, you can confidently choose a solution that delivers exceptional durability.

Summary Table:

| DLC Type | Typical Hardness (GPa) | Key Characteristics |

|---|---|---|

| a-C:H (Hydrogenated) | 10 - 25 GPa | Common, cost-effective, good balance of hardness and lubricity |

| ta-C (Tetrahedral) | 40 - 90+ GPa | Purest, hardest form, approaches diamond hardness |

| Hardened Steel (Reference) | 5 - 8 GPa | Baseline for comparison |

| Natural Diamond (Reference) | ~100 GPa | Hardest known material |

Ready to harness the power of DLC coatings for your components? KINTEK specializes in advanced lab equipment and consumables for surface engineering. Our expertise ensures you select the right coating solution—whether it's ultra-hard ta-C for extreme abrasion resistance or a balanced a-C:H for sliding parts—to maximize durability and performance. Contact our experts today to discuss how our solutions can enhance your laboratory's capabilities and protect your critical components.

Visual Guide

Related Products

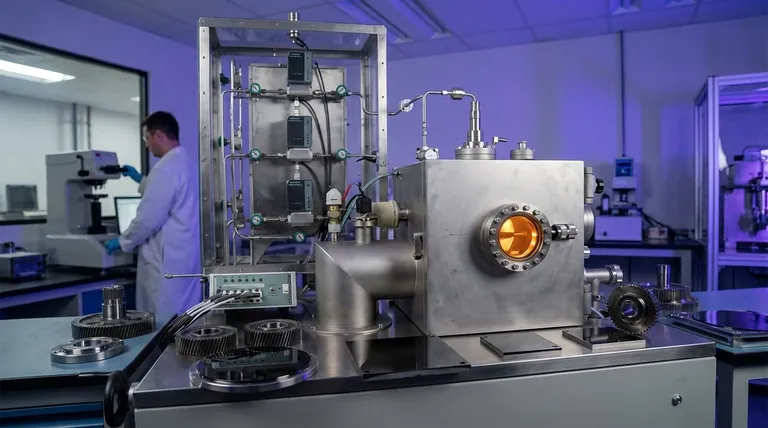

- Inclined Rotary Plasma Enhanced Chemical Vapor Deposition PECVD Equipment Tube Furnace Machine

- RF PECVD System Radio Frequency Plasma-Enhanced Chemical Vapor Deposition RF PECVD

- Chemical Vapor Deposition CVD Equipment System Chamber Slide PECVD Tube Furnace with Liquid Gasifier PECVD Machine

- CVD Diamond for Thermal Management Applications

- Electron Beam Evaporation Coating Oxygen-Free Copper Crucible and Evaporation Boat

People Also Ask

- Why is a Matching Network Indispensable in RF-PECVD for Siloxane Films? Ensure Stable Plasma and Uniform Deposition

- What are the process capabilities of ICPCVD systems? Achieve Low-Damage Film Deposition at Ultra-Low Temperatures

- Why does a PECVD vacuum system require both a rotary vane and turbo pump? Ensure High-Purity Coatings

- What is the process of PECVD in semiconductor? Enabling Low-Temperature Thin Film Deposition

- How are thin films deposited? A Guide to PVD vs. CVD Methods for Your Application