To be direct, heat treatment is the process of using controlled heating and cooling to deliberately alter the internal microstructure of a metal. This manipulation of the atomic arrangement—specifically the size, shape, and distribution of its crystal grains and phases—is what determines the material's final mechanical properties, such as its hardness, toughness, and ductility.

The core principle is this: heat treatment does not change a metal's chemical composition, but rather it reorganizes its internal architecture to achieve a desired set of engineering properties.

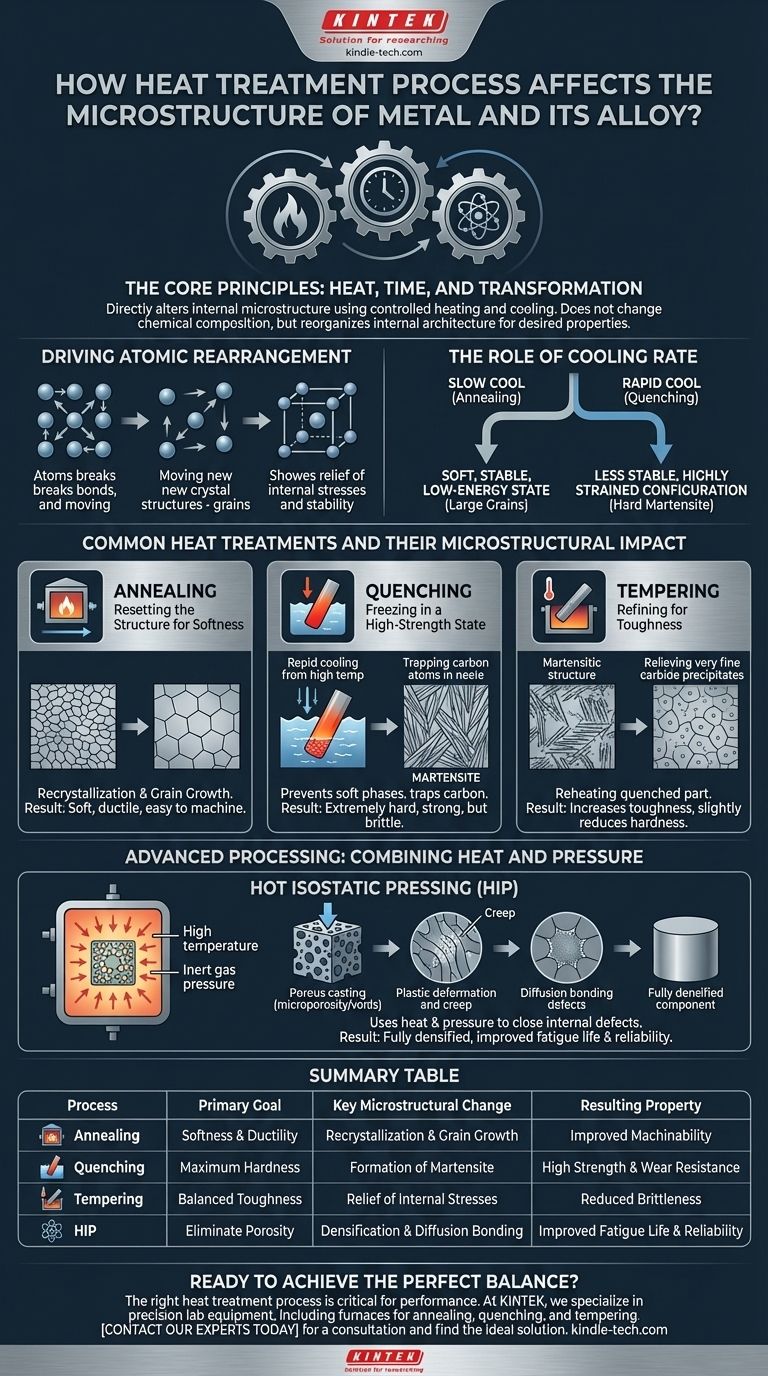

The Core Principles: Heat, Time, and Transformation

Heat treatment works by providing thermal energy that allows the atoms within the metal's crystal lattice to move. By carefully controlling the temperature, the duration of heating, and especially the rate of cooling, we can dictate the final structure.

Driving Atomic Rearrangement

Heating a metal gives its atoms the energy needed to break bonds and move. This allows internal stresses to be relieved and for new, more stable crystal structures (grains) to form and grow.

The Role of Cooling Rate

The cooling rate is often the most critical variable. A slow cool allows atoms ample time to settle into a soft, stable, low-energy state. A rapid cool (quenching), however, can trap atoms in a less stable, highly strained configuration, creating a much harder and stronger microstructure.

Common Heat Treatments and Their Microstructural Impact

Different heat treatment processes are designed to produce specific microstructures and, therefore, specific material properties.

Annealing: Resetting the Structure for Softness

Annealing involves heating a metal to a specific temperature and then cooling it very slowly. This process causes recrystallization, where new, strain-free grains form, and grain growth, where these new grains grow larger. The result is a uniform microstructure with large, equiaxed grains, which makes the metal softer, more ductile, and easier to machine or form.

Quenching: Freezing in a High-Strength State

Quenching is the process of cooling a metal very rapidly from a high temperature, typically by immersing it in water, oil, or air. For steels, this rapid cooling prevents the formation of softer phases and instead traps the carbon atoms in a highly strained, needle-like crystal structure called martensite. This microstructure is extremely hard and strong but also very brittle.

Tempering: Refining for Toughness

A metal that has been quenched is often too brittle for practical use. Tempering is a secondary treatment where the quenched part is reheated to a lower temperature. This process provides just enough energy to relieve some of the internal strain from the martensite and allow for the formation of very fine carbide precipitates. This slightly reduces hardness but significantly increases the material's toughness.

Understanding the Trade-offs

Choosing a heat treatment process is always a matter of balancing competing properties. It is crucial to understand the inherent compromises.

Hardness vs. Toughness

This is the most fundamental trade-off. Processes that maximize hardness, like quenching, almost always reduce toughness, making the material more brittle. Processes that enhance toughness, like annealing, do so at the expense of hardness and strength. Tempering is the act of deliberately navigating this compromise.

Dimensional Control and Distortion

The rapid temperature changes involved in quenching cause significant internal stresses. This can lead to warping, distortion, or even cracking of the component, which requires careful process control to manage.

Advanced Processing: Combining Heat and Pressure

Some material challenges cannot be solved by heat alone. For these cases, thermomechanical processes that combine heat with high pressure offer unique solutions.

Hot Isostatic Pressing (HIP)

The HIP process uses both high temperature and inert gas pressure to fundamentally change the microstructure. It forces the plastic deformation and creep of the material at a microscopic level.

This mechanism physically closes and diffusion bonds internal defects like microporosity and voids that are common in castings or powder metallurgy parts. The result is a fully densified component with a clean, uniform microstructure, significantly improving fatigue life and reliability for critical applications.

Matching the Process to Your Engineering Goal

The right heat treatment is entirely dependent on the intended function of the component.

- If your primary focus is maximum softness and formability: Annealing is the correct process to create a uniform, stress-free microstructure.

- If your primary focus is maximum hardness and wear resistance: Quenching is required to create a hard martensitic structure, but be prepared to manage brittleness.

- If your primary focus is a balanced combination of strength and toughness: A quench and temper process is the industry standard for achieving robust mechanical properties.

- If your primary focus is eliminating internal defects like porosity in a cast part: An advanced process like Hot Isostatic Pressing (HIP) is necessary to achieve full densification.

Ultimately, understanding heat treatment is the key to unlocking the full performance potential of a metallic material for its intended application.

Summary Table:

| Process | Primary Goal | Key Microstructural Change | Resulting Property |

|---|---|---|---|

| Annealing | Softness & Ductility | Recrystallization & Grain Growth | Improved Machinability |

| Quenching | Maximum Hardness | Formation of Martensite | High Strength & Wear Resistance |

| Tempering | Balanced Toughness | Relief of Internal Stresses | Reduced Brittleness |

| Hot Isostatic Pressing (HIP) | Eliminate Porosity | Densification & Diffusion Bonding | Improved Fatigue Life & Reliability |

Ready to achieve the perfect balance of properties in your metal components? The right heat treatment process is critical for performance. At KINTEK, we specialize in precision lab equipment, including furnaces for annealing, quenching, and tempering, to help you control microstructure and unlock your material's potential.

Let's discuss your application needs and find the ideal solution. Contact our experts today for a consultation!

Visual Guide

Related Products

- Vacuum Heat Treat Furnace with Ceramic Fiber Liner

- Molybdenum Vacuum Heat Treat Furnace

- Vacuum Heat Treat Sintering Brazing Furnace

- 2200 ℃ Tungsten Vacuum Heat Treat and Sintering Furnace

- Vacuum Heat Treat and Molybdenum Wire Sintering Furnace for Vacuum Sintering

People Also Ask

- Why do you vacuum for heat treatment? Achieve Flawless, High-Performance Metal Components

- What is vacuum heat treatment process? Achieve Superior Control, Cleanliness, and Quality

- How to vacuum out a furnace? A Step-by-Step Guide to Safe DIY Maintenance

- What is a vacuum furnace used for? Unlock High-Purity Heat Treatment for Superior Materials

- What are the advantages of vacuum hardening? Achieve Superior Precision and Cleanliness for Critical Components