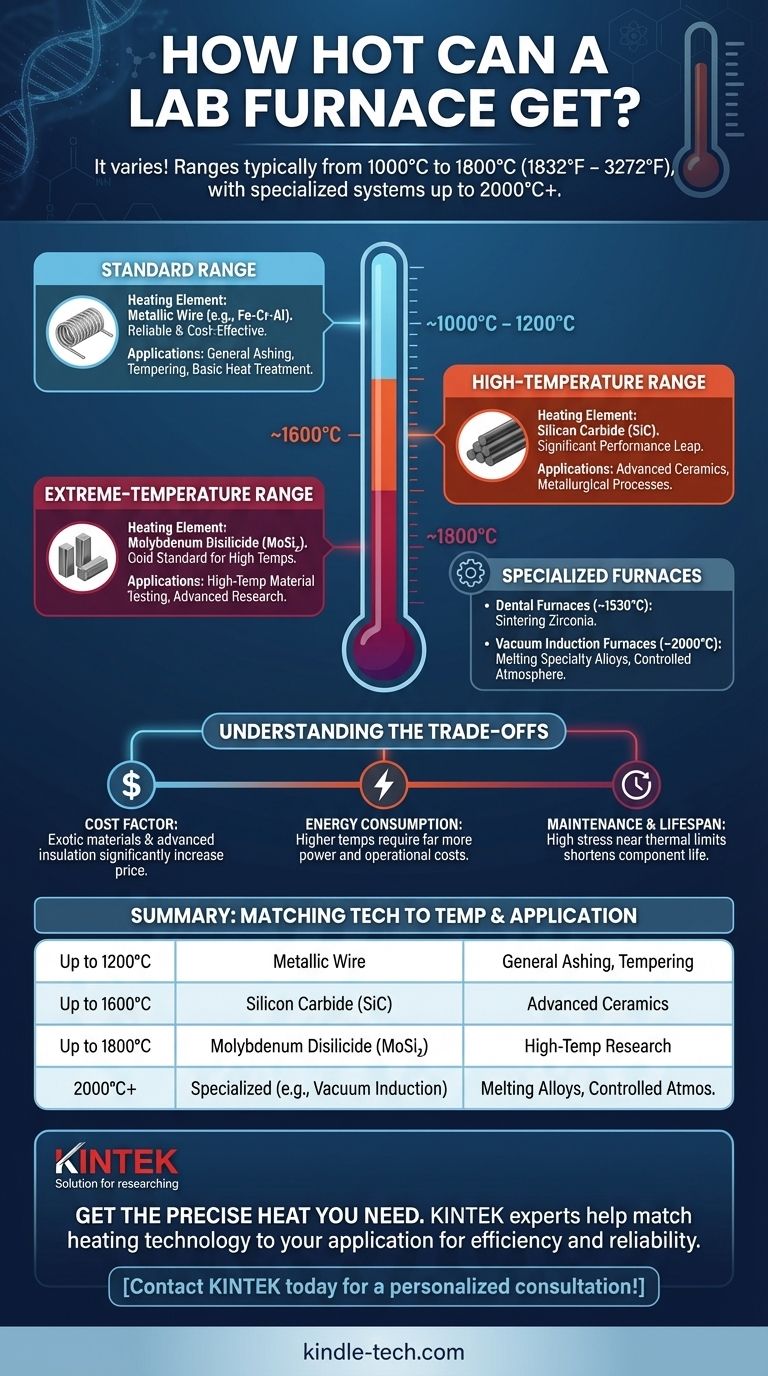

In short, a laboratory furnace's maximum temperature is not a single value. It typically ranges from 1000°C to 1800°C (1832°F to 3272°F), with highly specialized systems reaching 2000°C or more. The specific temperature a furnace can achieve is determined entirely by its design, particularly the material used for its heating elements.

The question isn't just "how hot can it get," but "what technology is required to reach the temperature I need?" A furnace's maximum heat is a direct reflection of its internal components, and choosing the right one means matching this technology to your specific application.

What Determines a Furnace's Maximum Temperature?

The single most important factor limiting a laboratory furnace's heat is the material of its heating elements. Different materials can withstand different temperature extremes before they degrade or fail.

The Three Tiers of Heating Element Technology

The vast majority of lab chamber furnaces use one of three types of heating elements, which create clear temperature tiers.

-

Standard Range: Metallic Wire (~1000°C – 1200°C) These are the most common elements, often made of iron-chromium-aluminum alloys. They are reliable and cost-effective for a wide range of general-purpose applications.

-

High-Temperature Range: Silicon Carbide (SiC) (~1600°C) For applications requiring temperatures beyond the reach of metallic elements, silicon carbide rods are used. They are more brittle and expensive but offer a significant leap in performance.

-

Extreme-Temperature Range: Molybdenum Disilicide (MoSi₂) (~1800°C) This is the gold standard for high-temperature laboratory chamber furnaces. These elements can operate consistently at very high temperatures, making them essential for advanced ceramics and materials research.

Specialized Furnaces for Unique Demands

Some processes require even higher temperatures or specific atmospheric conditions, leading to specialized designs.

-

Dental Furnaces (~1530°C): These are precisely calibrated to process specific dental materials, such as zirconium oxides, which require high, controlled heat for sintering.

-

Vacuum Induction Furnaces (~2000°C): For melting metals or advanced material synthesis without oxidation, these furnaces use electromagnetic induction to heat a crucible inside a vacuum. This specialized design allows them to reach temperatures far beyond conventional chamber furnaces.

Understanding the Trade-offs

Simply choosing the furnace with the highest possible temperature is often a mistake. Higher heat capability comes with significant trade-offs that impact budget and operations.

The Cost Factor

Exotic heating elements like Molybdenum Disilicide (MoSi₂) and the advanced insulation required to contain 1800°C are substantially more expensive than standard metallic wire components.

Energy Consumption

The energy required to reach and maintain extreme temperatures is significant. A furnace running at 1800°C will consume far more power than one operating at 1100°C, leading to higher operational costs.

Maintenance and Component Lifespan

Operating any material near its thermal limit causes stress. High-temperature elements have a finite lifespan and are more costly to replace, increasing the long-term cost of ownership.

Selecting the Right Temperature Range for Your Application

Choosing a furnace requires a clear understanding of your goals. Over-specifying is wasteful, while under-specifying will make your work impossible.

- If your primary focus is general ashing, tempering, or basic materials heat treatment: A standard furnace with metallic elements reaching up to 1200°C is the most efficient and cost-effective choice.

- If your primary focus is working with advanced ceramics, certain metallurgical processes, or high-temperature material testing: You will need a furnace with Silicon Carbide or Molybdenum Disilicide elements capable of reaching 1600°C to 1800°C.

- If your primary focus is melting specialty alloys or research in a controlled atmosphere: You require a highly specialized system, such as a vacuum induction furnace, designed for temperatures of 2000°C or more.

Matching the furnace's heating technology to your specific temperature requirement is the key to achieving reliable results efficiently.

Summary Table:

| Temperature Range | Common Heating Element | Typical Applications |

|---|---|---|

| Up to 1200°C | Metallic Wire (e.g., Iron-Chromium-Aluminum) | General ashing, tempering, basic heat treatment |

| Up to 1600°C | Silicon Carbide (SiC) | Advanced ceramics, certain metallurgical processes |

| Up to 1800°C | Molybdenum Disilicide (MoSi₂) | High-temperature material testing, advanced research |

| 2000°C+ | Specialized (e.g., Induction in Vacuum) | Melting specialty alloys, controlled atmosphere research |

Get the Precise Heat You Need for Your Lab

Choosing the wrong furnace temperature capability can lead to failed experiments, damaged samples, and wasted budget. The experts at KINTEK understand that the right furnace isn't just about maximum heat—it's about matching the heating element technology to your specific application for efficiency, reliability, and cost-effectiveness.

Whether you require a standard furnace for general lab work or a high-temperature system for advanced materials research, we provide the equipment and consumables to ensure your success.

Let our specialists help you select the perfect furnace for your requirements. Contact KINTEK today for a personalized consultation!

Visual Guide

Related Products

- 1400℃ Laboratory High Temperature Tube Furnace with Alumina Tube

- 1700℃ Laboratory High Temperature Tube Furnace with Alumina Tube

- 1200℃ Split Tube Furnace with Quartz Tube Laboratory Tubular Furnace

- Vertical Laboratory Tube Furnace

- Laboratory Muffle Oven Furnace Bottom Lifting Muffle Furnace

People Also Ask

- What is the basic construction and temperature control mechanism of a laboratory tube furnace? Master Precision Heating for Your Lab

- Why is a quartz tube furnace utilized in the thermal oxidation of MnCr2O4 coatings? Unlock Precise Selective Oxidation

- What precautions should be taken when using a tube furnace? Ensure Safe, Effective High-Temperature Processing

- What materials are used for the tubes in tube furnaces? A Guide to Selecting the Right Tube for Your Process

- How does a high-temperature tube furnace facilitate the phase transformation of alumina products? Master Thermal Control