The temperature of a hydraulic press is not a fixed value but a direct consequence of its workload and efficiency. While a press at rest is at ambient temperature, a system in normal operation typically runs between 120°F and 140°F (49°C to 60°C). However, this can fluctuate significantly based on the system's design, maintenance, and the intensity of the work being performed.

The heat generated by a hydraulic press is the single most important indicator of its operational health. Understanding and managing this heat is not just about temperature; it's about controlling energy loss, preventing premature wear, and ensuring the machine's long-term reliability.

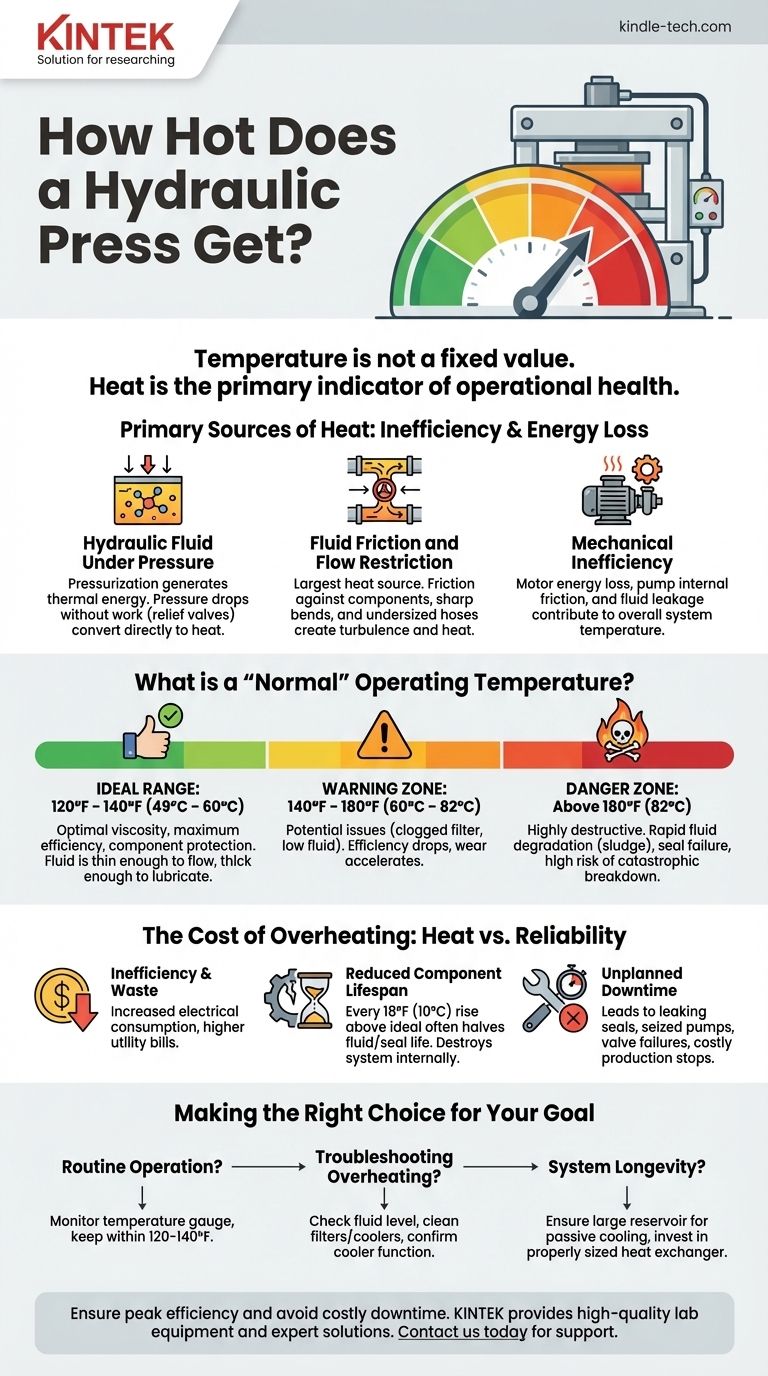

The Primary Sources of Heat in a Hydraulic System

Heat in a hydraulic system is fundamentally a byproduct of inefficiency. Every component that wastes energy, from the motor to the fluid itself, releases that wasted energy as heat.

Hydraulic Fluid Under Pressure

The act of pressurizing hydraulic fluid inherently generates some heat. As the fluid molecules are compressed, their internal energy increases, which is released as thermal energy.

More significantly, when high-pressure fluid moves to a lower-pressure area without performing work (like flowing over a relief valve), the pressure drop is converted directly into heat.

Fluid Friction and Flow Restriction

This is the largest source of heat in most hydraulic systems. As the hydraulic fluid is forced through hoses, pipes, fittings, and valves, it creates friction against the walls of these components.

Sharp bends, undersized hoses, or partially closed valves act as restrictions, forcing the fluid to speed up and creating turbulence. This friction and turbulence generate substantial heat.

Mechanical Inefficiency

No machine is 100% efficient. The electric motor driving the hydraulic pump loses some energy as heat. The pump itself has internal friction and fluid leakage, which also generates heat.

These mechanical and hydraulic inefficiencies compound, contributing to the overall temperature of the system.

What is a "Normal" Operating Temperature?

While every system is different, there are established guidelines for hydraulic fluid temperatures that ensure optimal performance and lifespan.

The Ideal Range: 120°F – 140°F (49°C – 60°C)

In this temperature range, the hydraulic fluid maintains its designed viscosity (resistance to flow). The fluid is thin enough to flow efficiently but thick enough to lubricate moving parts and prevent metal-on-metal contact.

Operating within this ideal window ensures maximum efficiency and protects the system's components.

The Warning Zone: 140°F – 180°F (60°C – 82°C)

Temperatures consistently above 140°F (60°C) indicate a potential issue, such as a clogged filter, low fluid level, or an undersized cooling system. The system will still function, but efficiency drops and component wear accelerates.

The Danger Zone: Above 180°F (82°C)

Operating a hydraulic system above 180°F (82°C) is highly destructive. At this temperature, the hydraulic fluid begins to oxidize and break down rapidly.

This degradation creates sludge and varnish that can clog filters and valves. The fluid also becomes too thin, leading to poor lubrication. Rubber seals and hoses will harden, crack, and fail, causing leaks and catastrophic system failure.

Understanding the Trade-offs: Heat vs. Reliability

Managing heat is a critical balancing act. Ignoring it leads to significant long-term costs that far outweigh any perceived short-term gains.

The Cost of Inefficiency

Heat is literally wasted energy. An overheating system is consuming more electrical power than necessary to perform its work, leading to higher utility bills.

The Impact on Component Lifespan

Excessive heat is the primary enemy of hydraulic components. For every 18°F (10°C) increase above the ideal range, the life of the hydraulic fluid and seals is often cut in half. An overheating press is actively destroying itself from the inside out.

The Risk of Unplanned Downtime

A press that runs too hot is a press that is destined to fail. This failure can manifest as a leaking seal, a seized pump, or a malfunctioning valve, all of which lead to costly, unplanned production stops.

Making the Right Choice for Your Goal

Your approach to managing heat should depend on your specific operational context.

- If your primary focus is routine daily operation: Monitor the system's temperature gauge and ensure it stays within the ideal 120°F-140°F range.

- If your primary focus is troubleshooting an overheating press: Start by checking the basics: ensure the fluid reservoir is at the correct level, check for clogged filters or strainers, and confirm the system's cooler (if equipped) is clean and functioning.

- If your primary focus is system longevity and performance: Ensure the hydraulic reservoir is large enough to allow for passive cooling (a general rule is 3-5 times the pump's GPM rating). For demanding applications, investing in a properly sized heat exchanger (oil cooler) is the most effective solution.

By viewing heat not as a simple temperature reading but as a critical symptom of system health, you can ensure your hydraulic press operates safely and productively for its entire service life.

Summary Table:

| Temperature Range | Status | Key Implications |

|---|---|---|

| 120°F – 140°F (49°C – 60°C) | Ideal | Optimal viscosity, maximum efficiency, and component longevity. |

| 140°F – 180°F (60°C – 82°C) | Warning | Accelerated wear, reduced efficiency, potential for system issues. |

| Above 180°F (82°C) | Danger | Rapid fluid degradation, seal failure, high risk of catastrophic breakdown. |

Ensure your hydraulic press operates at peak efficiency and avoid costly unplanned downtime. At KINTEK, we specialize in providing high-quality lab equipment and consumables, including hydraulic press systems designed for reliability and longevity. Our experts can help you select the right equipment or troubleshoot overheating issues to protect your investment.

Contact us today to discuss your specific laboratory needs and discover how KINTEK can enhance your operational performance.

Visual Guide

Related Products

- Laboratory Hydraulic Press Split Electric Lab Pellet Press

- Manual High Temperature Heated Hydraulic Press Machine with Heated Plates for Lab

- Automatic High Temperature Heated Hydraulic Press Machine with Heated Plates for Lab

- Laboratory Hydraulic Press Lab Pellet Press Machine for Glove Box

- Manual Heated Hydraulic Press Machine with Heated Plates for Laboratory Hot Press

People Also Ask

- Why are precise temperature and pressure controls in a Laboratory Hot Press essential for PBAT composites?

- What temperature is a heat press lamination? Find the Perfect Heat for a Flawless Finish

- Why is low-pressure hot pressing performed before CIP for electrodes? Ensure Perfect Alignment & Bonding

- What are the three types of lamination? Choose the Perfect Finish for Your Print Project

- Is a heat press machine good for t-shirts? Unlock Professional, Custom Apparel Creation

- What materials can be hot forged? A Guide to Metals with High Forgeability

- What role does a precision hot press play in the fabrication of TlBr crystals? Optimize Semiconductor Performance

- What is the purpose of using a hot press for sulfide solid-state electrolytes? Achieve Theoretical Density.