In short, a hydraulic press itself is not inherently hot. The large steel frame and ram typically remain near the ambient temperature of the workshop. The significant heat is generated within the hydraulic power unit that drives the press, and the critical temperature to monitor is that of the hydraulic fluid.

A hydraulic press generates heat not from its pressing action, but from the inefficiencies within its hydraulic system. The temperature of the hydraulic fluid is the critical factor, and managing this heat is essential for the machine's longevity, safety, and performance.

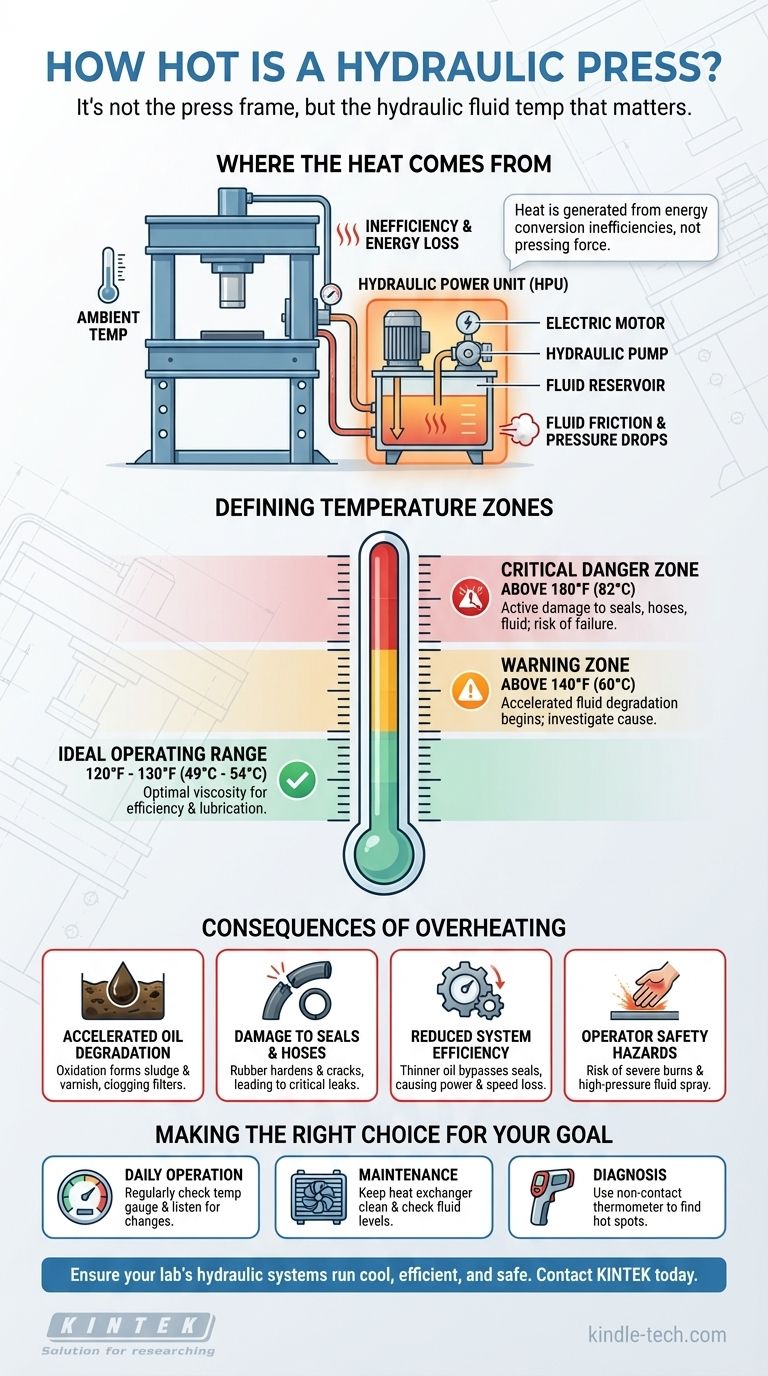

Where the Heat Actually Comes From

Understanding the source of heat is the first step to managing it. The heat doesn't come from the force of the press but from the energy conversion required to create that force.

The Hydraulic Power Unit (HPU)

The heart of the system—and the source of the heat—is the HPU. This unit contains the electric motor, the hydraulic pump, and the fluid reservoir. All the action happens here.

Inefficiency is the Primary Culprit

Every time energy is converted from one form to another (electrical to mechanical to fluid pressure), some energy is lost as waste heat. This is a fundamental law of physics. A perfectly efficient system would generate no heat, but no such system exists.

Fluid Friction and Pressure Drops

As hydraulic fluid is forced through hoses, valves, and fittings, friction between the fluid and the surfaces generates heat. The most significant source of heat often comes from a large pressure drop without performing useful work, such as when a relief valve opens and dumps high-pressure fluid directly back to the low-pressure reservoir.

Defining "Normal" vs. "Too Hot"

Knowing the specific temperature thresholds is crucial for safe and effective operation. These are general guidelines; always consult your machine's specific manual.

The Ideal Operating Range

Most hydraulic systems are designed to operate with the fluid temperature between 120°F and 130°F (49°C to 54°C). In this range, the fluid has the optimal viscosity (thickness) to lubricate components and transmit power efficiently.

The Warning Zone

As temperatures rise above 140°F (60°C), the hydraulic fluid begins to break down at an accelerated rate. This temperature should be a signal to investigate the cause of the excess heat.

The Critical Danger Zone

Operating a hydraulic system with fluid temperatures above 180°F (82°C) is a serious problem. At this point, damage to seals, hoses, and the fluid itself is actively occurring, leading to premature system failure.

The Consequences of Overheating

Running a hydraulic system too hot isn't just inefficient; it's actively destructive. The damage caused by excessive heat can lead to costly downtime and repairs.

Accelerated Oil Degradation

Heat is the number one enemy of hydraulic oil. High temperatures cause the oil to oxidize, forming sludge and varnish that can clog filters and gum up sensitive valve components.

Damage to Seals and Hoses

Most seals and hoses in hydraulic systems are made from synthetic rubber compounds. Excessive heat causes these materials to harden and become brittle, leading to cracks and, eventually, critical fluid leaks.

Reduced System Efficiency

As hydraulic oil gets hotter, its viscosity drops, meaning it becomes thinner. Thinner oil can bypass internal seals in pumps, cylinders, and valves more easily. This internal leakage reduces the system's power and speed, making it sluggish and inefficient.

Operator Safety Hazards

An overheating system poses direct risks. Components, especially the HPU and hoses, can become hot enough to cause severe burns. Furthermore, a hose that fails catastrophically due to heat degradation can spray high-pressure, high-temperature fluid, creating a significant safety incident.

Making the Right Choice for Your Goal

Proper temperature management is about proactive monitoring and maintenance, not reactive repairs.

- If your primary focus is daily operation: Regularly check the system's temperature gauge. Be aware of the machine's normal operating sound and feel; a significant change can indicate a problem like a bypassing relief valve.

- If your primary focus is maintenance: Keep the heat exchanger (oil cooler) fins clean and free of dust and debris to ensure maximum cooling efficiency. Check the hydraulic fluid level regularly, as a low level reduces the system's ability to dissipate heat.

- If your primary focus is diagnosing a problem: Use a non-contact infrared thermometer to identify specific hot spots. A component that is significantly hotter than the rest of the system, like a single valve or the pump, is a clear indicator of where the fault lies.

Ultimately, managing the heat in a hydraulic system is the key to ensuring its reliability, safety, and long-term performance.

Summary Table:

| Temperature Range | Status | Key Implications |

|---|---|---|

| 120°F - 130°F (49°C - 54°C) | Ideal Operating Range | Optimal fluid viscosity for efficiency and lubrication. |

| Above 140°F (60°C) | Warning Zone | Accelerated fluid degradation begins; investigate the cause. |

| Above 180°F (82°C) | Critical Danger Zone | Active damage to seals, hoses, and fluid; risk of system failure. |

Is your hydraulic press operating at a safe temperature? Proper temperature management is critical for the longevity, safety, and performance of your equipment. KINTEK specializes in high-performance lab equipment and consumables, including solutions for maintaining optimal hydraulic system conditions. Our experts can help you select the right monitoring tools and maintenance supplies to prevent costly downtime and repairs. Contact our team today to ensure your lab's hydraulic systems run cool, efficient, and safe.

Visual Guide

Related Products

- Laboratory Hydraulic Press Split Electric Lab Pellet Press

- Manual Lab Heat Press

- Automatic Laboratory Hydraulic Press for XRF & KBR Pellet Press

- Laboratory Hydraulic Press Lab Pellet Press Machine for Glove Box

- Manual High Temperature Heated Hydraulic Press Machine with Heated Plates for Lab

People Also Ask

- How does a three-stage pressure program affect rice husk particleboards? Optimize Bond Strength & Stability

- What is the use of a hot press machine? Achieve Superior Material Bonding and Forming

- How does a programmable hot press contribute to the manufacturing of NiO-YSZ anode supports for fuel cells?

- What is hot press vs cold press machine? Choose the Right Method for Your Materials

- What are the primary challenges in hot press platen temperature control? Expert Thermal Efficiency Guide

- What environmental conditions does a laboratory hot press provide? Optimize Dry Electrode Densification

- What are heated hydraulic presses used for? Molding Composites, Vulcanizing Rubber, and More

- How does a precision hot press influence PEM electrolysis stack performance? Optimize Efficiency and Durability.