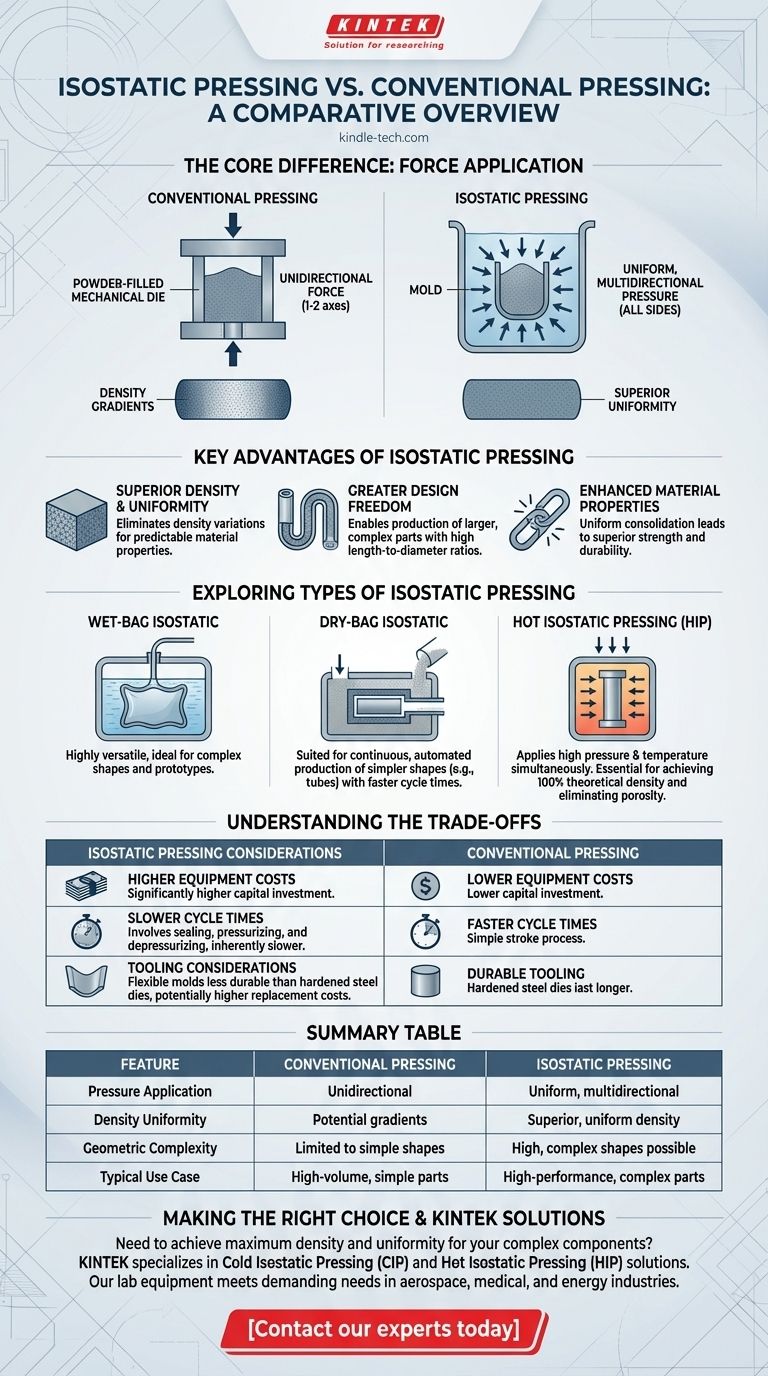

The fundamental distinction between isostatic and conventional pressing lies in how pressure is applied to the material. Conventional pressing uses a mechanical die to apply force from one or two directions, whereas isostatic pressing uses a fluid medium to apply uniform, equal pressure from all directions simultaneously. This difference in application method dramatically impacts the final component's density, uniformity, and geometric complexity.

While conventional pressing applies force along a single axis, creating potential density variations, isostatic pressing uses a fluid to apply equal pressure from all directions. This results in highly uniform components with superior material properties and greater design freedom.

The Core Difference: Unidirectional vs. Multidirectional Force

The method of compaction is the defining factor that separates these two processes. Each approach is suited for different outcomes and manufacturing goals.

Conventional Pressing: Unidirectional Force

Conventional methods, like die pressing, compact a powder by applying force along a single axis (uniaxial).

This approach is fast and cost-effective for simple shapes but can create density gradients within the part. Friction between the powder and the die walls prevents pressure from being transmitted evenly throughout the component.

Isostatic Pressing: Uniform, Multidirectional Pressure

Isostatic pressing places the powder in a flexible mold and immerses it in a fluid, which is then pressurized. This applies an equal, simultaneous force to every surface of the component.

This method achieves intimate contact between particles without the geometrical limitations of a rigid die. The result is a "green" part with maximum uniformity and density, as it effectively consolidates internal voids and defects.

Key Advantages of Isostatic Pressing

Choosing isostatic pressing provides distinct benefits that are often critical for high-performance applications.

Superior Density and Uniformity

Because pressure is applied from all sides, isostatic pressing eliminates the density variations common in conventional methods. This uniformity leads to more predictable and reliable material properties after final processing, like sintering.

Greater Design Freedom

Without the constraints of a rigid die, isostatic pressing enables the production of larger and more complex components. It significantly increases the allowable length-to-diameter ratios, making it ideal for long, thin-walled products.

Enhanced Material Properties

The uniform consolidation of particles and elimination of internal defects result in superior final material properties. This is crucial for components that must withstand extreme stress, temperature, or fatigue.

Exploring the Types of Isostatic Pressing

Isostatic pressing is not a single technique but a family of processes, each tailored to specific needs.

Wet-Bag Isostatic Pressing

In this method, the powder-filled mold is sealed and fully immersed in the high-pressure liquid.

This process is highly versatile and ideal for producing complex shapes, prototypes, or small production runs where tooling changes are frequent.

Dry-Bag Isostatic Pressing

Here, the flexible mold is integrated into the pressure vessel itself, and the powder is loaded "dry" without the mold being removed.

This approach is better suited for continuous, automated production of simpler shapes like tubes or rods, offering faster cycle times than the wet-bag method.

Hot Isostatic Pressing (HIP)

HIP is a secondary process that applies both high pressure and high temperature simultaneously. It is often used after sintering to eliminate any remaining porosity.

This technique is used to achieve 100% of the theoretical maximum density, which is essential for the most demanding applications in aerospace, medical, and energy industries.

Understanding the Trade-offs

While powerful, isostatic pressing is not always the optimal choice. It involves clear trade-offs compared to conventional methods.

Higher Equipment Costs

The high-pressure vessels and complex control systems required for isostatic pressing represent a significantly higher capital investment than a standard mechanical press.

Slower Cycle Times

The process of sealing a mold, placing it in a vessel, pressurizing, and depressurizing is inherently slower than the simple stroke of a conventional press. Dry-bag pressing helps mitigate this but is still generally slower.

Tooling Considerations

Flexible molds used in isostatic pressing can be less durable than the hardened steel dies of conventional methods, potentially leading to higher tooling replacement costs over time.

Making the Right Choice for Your Goal

Selecting the correct pressing method depends entirely on your project's specific requirements for geometry, performance, and production volume.

- If your primary focus is high-volume production of simple shapes: Conventional die pressing offers unmatched speed and cost-effectiveness.

- If your primary focus is maximum uniformity and complex geometries in a pre-sintered part: Cold Isostatic Pressing (CIP) is the superior choice for creating a green part without internal defects.

- If your primary focus is eliminating all porosity for critical, high-performance applications: Hot Isostatic Pressing (HIP) is the definitive method for achieving full theoretical density in a final component.

Ultimately, understanding this fundamental difference in pressure application empowers you to select the precise manufacturing process for your material and performance goals.

Summary Table:

| Feature | Conventional Pressing | Isostatic Pressing |

|---|---|---|

| Pressure Application | Unidirectional (1-2 axes) | Uniform, multidirectional (all sides) |

| Density Uniformity | Potential gradients | Superior, uniform density |

| Geometric Complexity | Limited to simple shapes | High, complex shapes possible |

| Typical Use Case | High-volume, simple parts | High-performance, complex parts |

Need to achieve maximum density and uniformity for your complex components?

KINTEK specializes in isostatic pressing solutions, including Cold Isostatic Pressing (CIP) and Hot Isostatic Pressing (HIP), to help you produce components with superior material properties and minimal defects. Our lab equipment and consumables are designed to meet the demanding needs of industries like aerospace, medical, and energy.

Contact our experts today to discuss how our isostatic pressing expertise can enhance your manufacturing process and product performance.

Visual Guide

Related Products

- Warm Isostatic Press WIP Workstation 300Mpa for High Pressure Applications

- Double Plate Heating Press Mold for Lab

- Laboratory Sterilizer Lab Autoclave Vertical Pressure Steam Sterilizer for Liquid Crystal Display Automatic Type

- Single Punch Tablet Press Machine and Mass Production Rotary Tablet Punching Machine for TDP

- Vacuum Hot Press Furnace Machine for Lamination and Heating

People Also Ask

- What is the principle of hot isostatic pressing? Achieve 100% Density and Superior Performance

- Is hot isostatic pressing a heat treatment? A Guide to Its Unique Thermomechanical Process

- What pressure is hot isostatic press? Achieve Full Density & Superior Material Performance

- What is HIP in material processing? Achieve Near-Perfect Density for Critical Components

- How much energy does hot isostatic pressing consume? Unlock Net Energy Savings in Your Process