At its core, the difference is the energy source. While conventional Chemical Vapor Deposition (CVD) uses high heat to drive chemical reactions, Plasma-Enhanced Chemical Vapor Deposition (PECVD) uses an electrical field to create plasma, which provides the energy instead. This fundamental distinction allows PECVD to operate at significantly lower temperatures, opening up a range of possibilities and trade-offs compared to its thermal counterpart.

The choice between PECVD and CVD is not about which is "better," but which is appropriate for the task. Your decision will be dictated primarily by your substrate's tolerance for heat and the specific film properties you need to achieve.

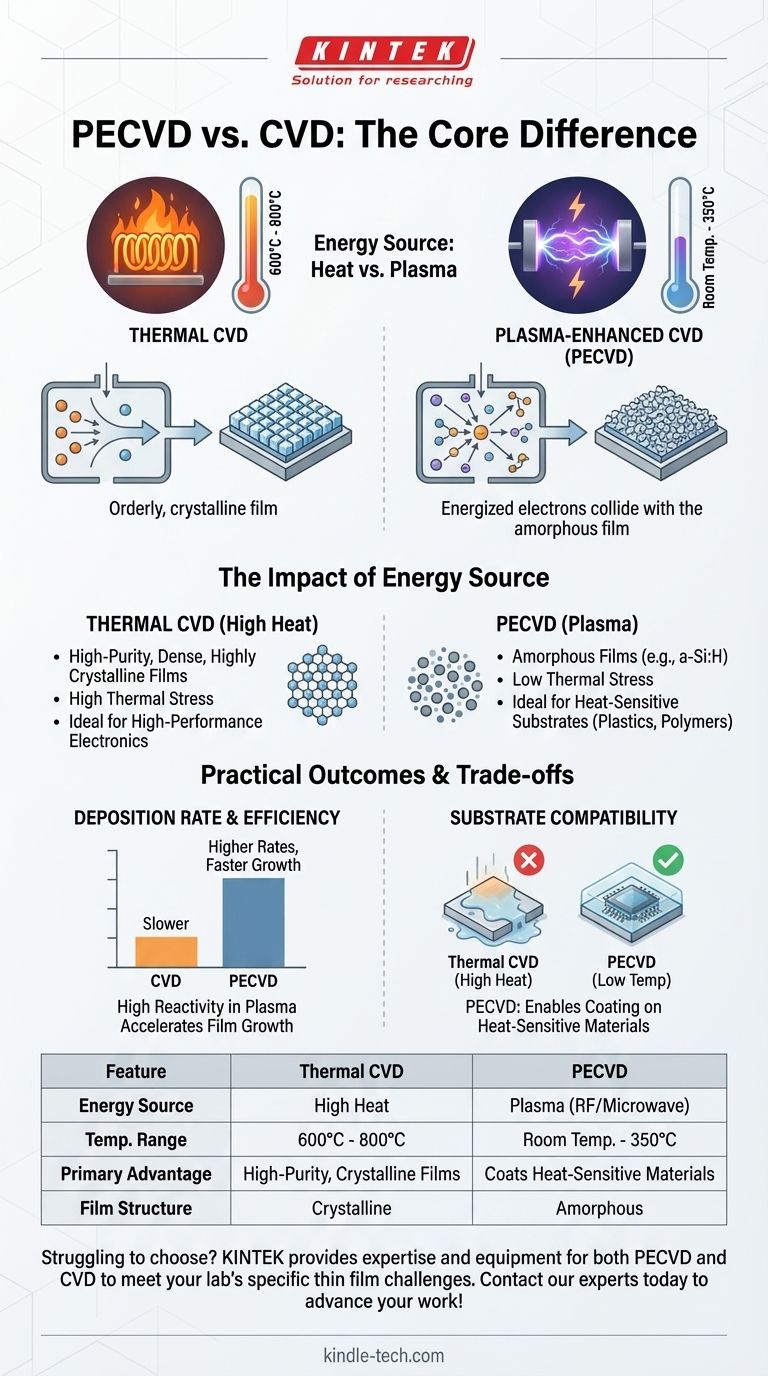

The Fundamental Difference: How Energy is Supplied

The goal of any CVD process is to supply enough energy to break down precursor gases into reactive species that then deposit as a thin film onto a substrate. How that energy is delivered is the primary point of divergence.

How Thermal CVD Works

Traditional thermal CVD relies on heat as its sole energy source. The substrate, the chamber, or both are heated to very high temperatures, typically between 600°C and 800°C.

This intense thermal energy provides the "activation energy" needed for the chemical reactions to occur, depositing the desired material onto the substrate surface. The process is governed by thermal equilibrium kinetics.

How PECVD Works

PECVD bypasses the need for extreme heat by introducing a different energy source: plasma. By applying a strong radio frequency (RF) or microwave field, the precursor gases are ionized into a state of matter containing high-energy electrons and ions.

These energetic electrons collide with gas molecules, breaking them apart into reactive radicals. Because the energy for the reaction comes from these collisions—not from heat—the process can run at much lower temperatures, often from room temperature up to 350°C.

The Impact of Plasma Chemistry

The use of plasma creates a non-equilibrium environment. The high-energy electrons effectively break chemical bonds non-selectively, forcing reactions that would not occur under purely thermal conditions.

This results in films with unique compositions and structures, which are often amorphous (lacking a crystalline structure) rather than the more ordered crystalline films typically grown with high-temperature thermal CVD.

Comparing Practical Outcomes

The difference in energy source leads to significant differences in process characteristics and final film quality.

Operating Temperature and Substrate Compatibility

This is the most critical distinction. PECVD's low-temperature process makes it ideal for depositing films on heat-sensitive substrates like plastics, polymers, or complex electronic devices that would be damaged or destroyed by the high heat of traditional CVD.

Film Structure and Properties

Thermal CVD is often used to produce high-purity, dense, and highly crystalline films. The high temperature allows atoms to arrange themselves into a stable, low-energy crystal lattice.

PECVD, by contrast, excels at creating amorphous films like amorphous silicon (a-Si:H) or silicon nitride (SiNx). The rapid, non-equilibrium deposition "freezes" atoms in place before they can form a perfect crystal structure, leading to unique optical and electrical properties.

Deposition Rate and Efficiency

PECVD processes can achieve significantly higher deposition rates than thermal CVD. The high reactivity of the species within the plasma accelerates the film growth, which can reduce processing time and cost.

Understanding the Trade-offs

Choosing a deposition method requires balancing the advantages and disadvantages of each technique.

The Advantage of Low Temperature (PECVD)

The primary benefit of PECVD is its low operating temperature. This dramatically reduces thermal stress on the substrate, prevents unwanted diffusion between layers, and enables coating on a vast range of materials that simply cannot withstand high heat.

The Need for High Temperature (CVD)

For many advanced semiconductor applications, a highly ordered crystalline structure is essential for optimal electronic performance. Achieving this level of quality often requires the high temperatures and equilibrium conditions provided only by thermal CVD.

Cost and Process Control

While PECVD's faster deposition can lower operational costs, the equipment required to generate and sustain a stable plasma is more complex than a simple thermal reactor. However, PECVD can sometimes simplify manufacturing by coating parts directly without complex masking steps.

Making the Right Choice for Your Application

Your final decision must be guided by your end goal, balancing the needs of your substrate with the desired characteristics of the final film.

- If your primary focus is coating heat-sensitive materials: PECVD is the only viable choice, as it prevents thermal damage to substrates like plastics or fully assembled electronics.

- If your primary focus is creating a highly-ordered, crystalline film: Thermal CVD is typically the required method, as the high heat is necessary for atoms to settle into a stable crystal lattice.

- If your primary focus is high deposition speed and creating unique amorphous films: PECVD provides significant advantages in both throughput and the ability to engineer novel material properties.

Ultimately, understanding the fundamental energy source—heat versus plasma—is the key to selecting the correct deposition technology for your specific engineering challenge.

Summary Table:

| Feature | Thermal CVD | PECVD |

|---|---|---|

| Energy Source | High Heat (600-800°C) | Plasma (RF/Microwave) |

| Typical Temp. Range | 600°C - 800°C | Room Temp. - 350°C |

| Primary Advantage | High-Purity, Crystalline Films | Coats Heat-Sensitive Materials |

| Typical Film Structure | Crystalline | Amorphous |

Struggling to choose the right deposition technology for your materials?

Whether you need to coat heat-sensitive polymers with PECVD or grow high-quality crystalline films with CVD, KINTEK has the expertise and equipment to meet your lab's specific thin film challenges. Our team can help you select the perfect solution to achieve the film properties and substrate compatibility your research demands.

Contact our experts today to discuss your application and discover how KINTEK's lab equipment can advance your work!

Visual Guide

Related Products

- Chemical Vapor Deposition CVD Equipment System Chamber Slide PECVD Tube Furnace with Liquid Gasifier PECVD Machine

- RF PECVD System Radio Frequency Plasma-Enhanced Chemical Vapor Deposition RF PECVD

- 1200℃ Split Tube Furnace with Quartz Tube Laboratory Tubular Furnace

- Vacuum Hot Press Furnace Machine for Lamination and Heating

- Multi-zone Laboratory Tube Furnace

People Also Ask

- How are thin films deposited? A Guide to PVD vs. CVD Methods for Your Application

- How does PECVD work? Enable Low-Temperature, High-Quality Thin Film Deposition

- What color diamonds are CVD? Understanding the Process from Brown Tint to Colorless Beauty

- What are the steps of the CVD process? A Guide to Precision Thin Film Deposition

- What are the different types of thin films? A Guide to Optical, Electrical, and Functional Coatings