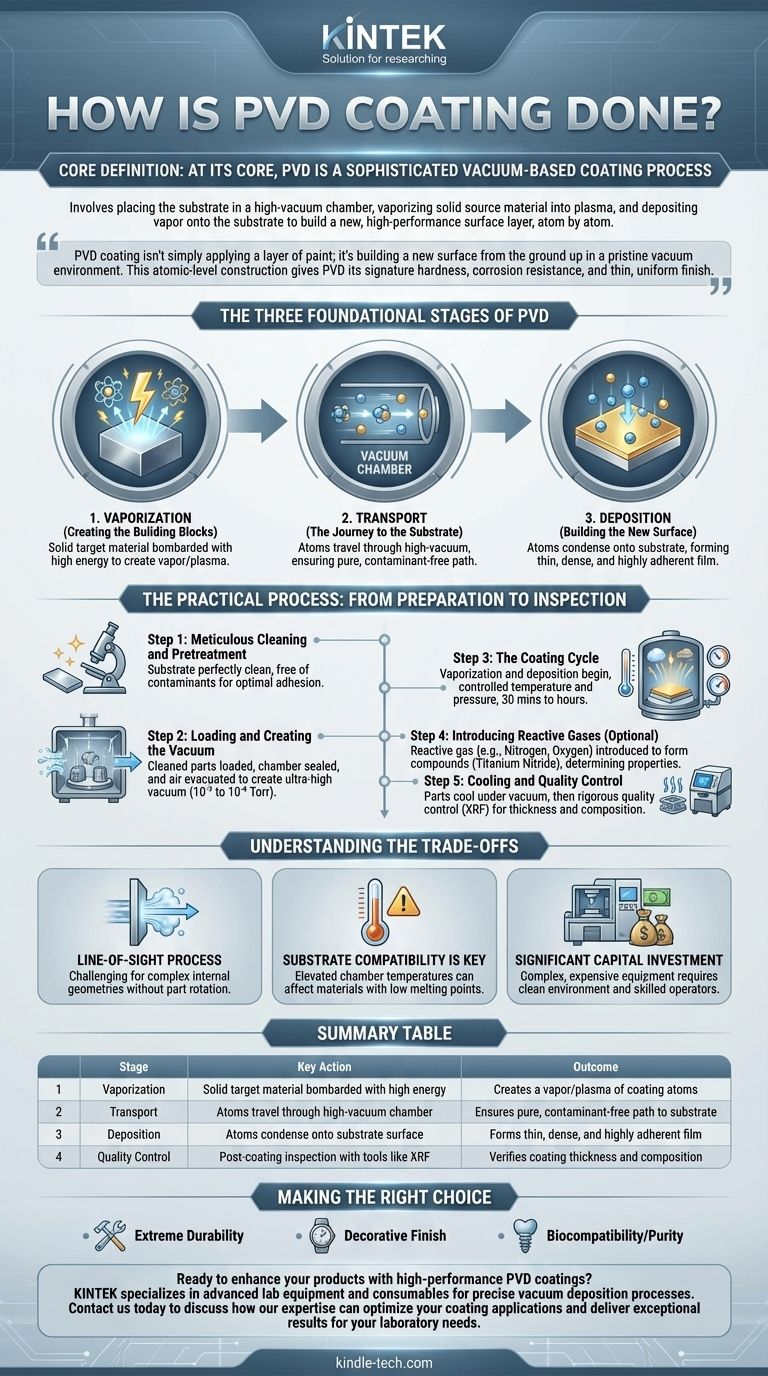

At its core, Physical Vapor Deposition (PVD) is a sophisticated vacuum-based coating process. It involves placing the object to be coated (the substrate) into a high-vacuum chamber, vaporizing a solid source material into a plasma of atoms or molecules, and then depositing that vapor onto the substrate to build a new, high-performance surface layer, atom by atom.

PVD coating isn't simply applying a layer of paint; it's building a new surface from the ground up in a pristine vacuum environment. This atomic-level construction is what gives PVD its signature hardness, corrosion resistance, and thin, uniform finish.

The Three Foundational Stages of PVD

While the full industrial process has several steps, the physics of the PVD process itself can be broken down into three foundational stages. Understanding these is key to understanding why the coating is so effective.

Stage 1: Vaporization (Creating the Building Blocks)

The process begins with the source material, or "target," which is a block of the pure material you want to use for the coating (e.g., titanium, zirconium, chromium).

This solid target is bombarded with a high-energy source, such as an electric arc or an ion beam. This bombardment has enough energy to knock atoms loose from the target, converting the solid material directly into a vapor or plasma.

Stage 2: Transport (The Journey to the Substrate)

Once vaporized, these atoms travel through the vacuum chamber from the target towards the substrate.

The vacuum is critical here. By removing virtually all other air and gas particles, it ensures there are no contaminants and that the vaporized atoms have a clear, unobstructed path to their destination.

Stage 3: Deposition (Building the New Surface)

When the vaporized atoms reach the substrate, they condense onto its surface.

Because this happens atom by atom, they form an extremely thin, dense, and highly adherent film. This controlled, layer-by-layer growth is what creates the exceptional uniformity and performance characteristics of a PVD coating.

The Practical Process: From Preparation to Inspection

In a real-world industrial setting, the foundational stages are part of a larger, highly controlled workflow designed for quality and repeatability.

Step 1: Meticulous Cleaning and Pretreatment

This is arguably the most critical step for a successful coating. The substrate must be perfectly clean, free of any oils, dust, oxides, or other contaminants.

Any imperfection on the surface will prevent the coating from adhering properly, leading to potential failure. Pretreatment may also be used to further enhance the surface for optimal bonding.

Step 2: Loading and Creating the Vacuum

The cleaned parts are carefully placed in the vacuum chamber along with the source material. The chamber is then sealed and powerful pumps evacuate the air.

This process creates an extremely low-pressure environment (typically 10⁻³ to 10⁻⁹ Torr), which is essential for the purity and quality of the final coating.

Step 3: The Coating Cycle

With the vacuum established, the vaporization and deposition process begins. The temperature and pressure inside the chamber are precisely controlled throughout the cycle.

This part of the process can take anywhere from 30 minutes to a few hours, depending on the material, coating thickness, and the size of the parts.

Step 4: Introducing Reactive Gases (Optional)

To create specific compounds, a reactive gas like nitrogen, oxygen, or methane can be introduced into the chamber during the transport stage.

The vaporized metal atoms react with the gas to form a ceramic compound (e.g., Titanium + Nitrogen → Titanium Nitride). This step is what determines many of the coating's final properties, including its hardness and color.

Step 5: Cooling and Quality Control

After the coating is deposited, the parts are allowed to cool under vacuum before the chamber is returned to atmospheric pressure.

Each batch is then subjected to rigorous quality control. Technicians often use tools like an X-ray fluorescent (XRF) machine to verify the coating's thickness and exact elemental composition, ensuring it meets all specifications.

Understanding the Trade-offs

PVD is a powerful technology, but it's important to understand its specific characteristics and limitations to determine if it's the right choice for your application.

It's a Line-of-Sight Process

The vaporized material travels in a relatively straight line from the target to the substrate. This means that coating complex internal geometries or deep, narrow holes can be challenging without sophisticated part-rotation mechanisms.

Substrate Compatibility is Key

The PVD process involves elevated temperatures inside the chamber. While not as hot as other processes like Chemical Vapor Deposition (CVD), the heat can still affect materials with low melting points, potentially limiting substrate choices.

It Requires Significant Capital Investment

PVD coating equipment is complex, precise, and expensive. The process requires a clean environment and skilled operators, making it best suited for high-performance applications where the benefits of durability and quality justify the cost.

Making the Right Choice for Your Application

Ultimately, the decision to use PVD coating depends entirely on your project's goals.

- If your primary focus is extreme durability and wear resistance: PVD's atom-by-atom deposition creates an exceptionally hard and dense film ideal for cutting tools and high-wear components.

- If your primary focus is a specific decorative finish with high performance: The ability to introduce reactive gases gives you precise control over color and luster, making PVD perfect for premium watches, fixtures, and consumer electronics.

- If your primary focus is biocompatibility or purity: The high-vacuum process ensures an extremely pure coating with no outgassing, which is critical for medical implants and food-grade equipment.

Understanding this atomic-level construction is the key to leveraging PVD's full potential for your specific needs.

Summary Table:

| PVD Coating Stage | Key Action | Outcome |

|---|---|---|

| Vaporization | Solid target material is bombarded with high energy | Creates a vapor/plasma of coating atoms |

| Transport | Atoms travel through high-vacuum chamber | Ensures pure, contaminant-free path to substrate |

| Deposition | Atoms condense onto substrate surface | Forms thin, dense, and highly adherent film |

| Quality Control | Post-coating inspection with tools like XRF | Verifies coating thickness and composition |

Ready to enhance your products with high-performance PVD coatings? KINTEK specializes in advanced lab equipment and consumables for precise vacuum deposition processes. Whether you're developing cutting tools, medical implants, or decorative finishes, our solutions ensure superior hardness, corrosion resistance, and uniformity. Contact us today to discuss how our expertise can optimize your coating applications and deliver exceptional results for your laboratory needs.

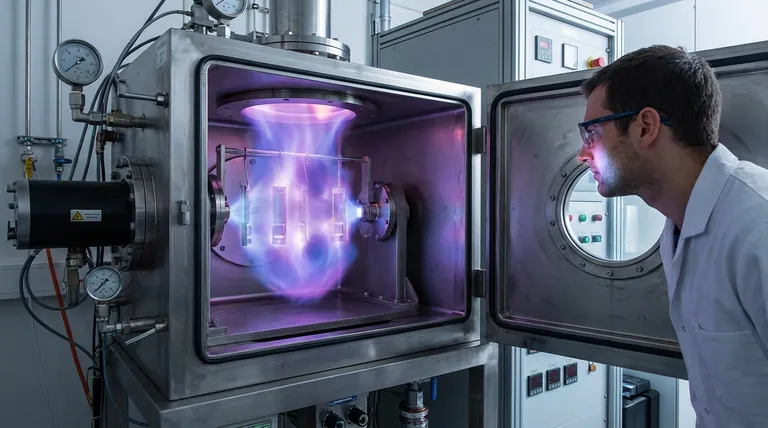

Visual Guide

Related Products

- Vacuum Hot Press Furnace Machine for Lamination and Heating

- 915MHz MPCVD Diamond Machine Microwave Plasma Chemical Vapor Deposition System Reactor

- HFCVD Machine System Equipment for Drawing Die Nano-Diamond Coating

- Laboratory Sterilizer Lab Autoclave Pulse Vacuum Lifting Sterilizer

- Laboratory Sterilizer Lab Autoclave Vertical Pressure Steam Sterilizer for Liquid Crystal Display Automatic Type

People Also Ask

- How does hot pressing work? Achieve Maximum Density for Advanced Materials

- What is hot press moulding? Achieve Superior Density and Complex Shapes with Heat and Pressure

- What is vacuum lamination? Achieve a Flawless, Durable Finish on Complex Shapes

- What are the advantages and disadvantages of hot stamping? Unlock Ultra-High Strength for Automotive Parts

- What is hot press forging? Creating Complex, High-Strength Metal Components