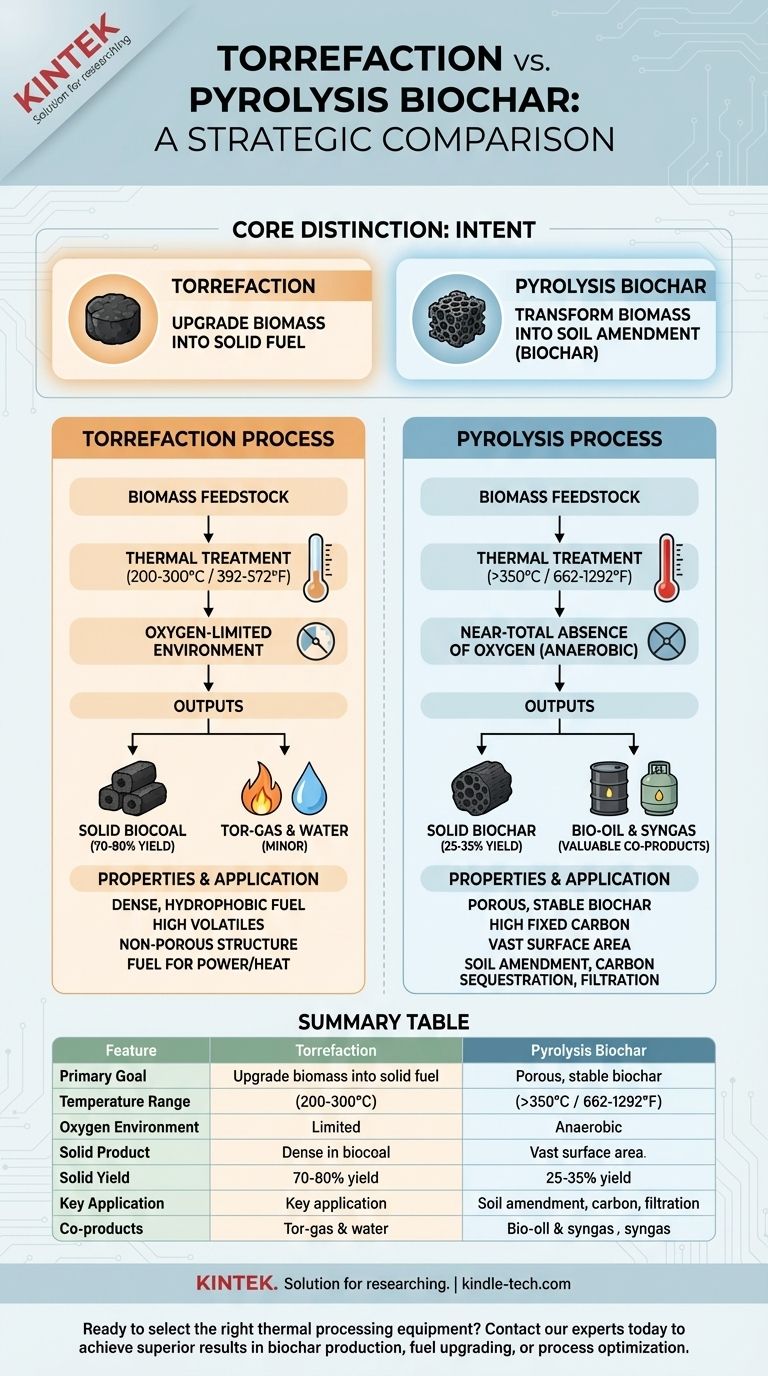

At a fundamental level, the difference between torrefaction and pyrolysis is the processing temperature and the resulting product's intended purpose. Torrefaction is a mild form of pyrolysis, conducted at low temperatures (200-300°C) with the primary goal of creating a densified, coal-like solid fuel. True pyrolysis operates at much higher temperatures (>350°C) in the complete absence of oxygen to thermally decompose biomass into three distinct products: biochar (a solid), bio-oil (a liquid), and syngas (a gas).

The core distinction is one of intent. Torrefaction aims to upgrade biomass into a better solid fuel. Pyrolysis is a more intensive process designed to transform biomass into a stable, carbon-rich soil amendment (biochar), alongside valuable liquid and gaseous co-products.

The Defining Factor: Thermal Treatment Conditions

The operational parameters are not just minor tweaks; they fundamentally alter the chemical reactions and the nature of the final solid material.

H3: Temperature Range Dictates Transformation

Torrefaction operates in a narrow, low-temperature window of 200-300°C (392-572°F). In this range, the process primarily drives off water and breaks down the less stable components of the biomass, like hemicellulose.

Pyrolysis for biochar production occurs at significantly higher temperatures, typically >350°C and often up to 700°C (662-1292°F). This intense heat is required to break down nearly all the volatile components, including cellulose and lignin, leaving behind a carbon-rich skeleton.

H3: Oxygen Environment

Torrefaction is performed in an oxygen-limited or inert environment. It's best described as a severe roasting process, where some minor oxidative reactions can still occur.

Pyrolysis, by contrast, must occur in a near-total absence of oxygen (anaerobic). The presence of oxygen at these high temperatures would cause the biomass to combust (burn) rather than thermally decompose, completely preventing the formation of biochar and bio-oil.

A Tale of Two Products: Torrefied Biomass vs. Biochar

The differences in process conditions lead to two solids with vastly different physical and chemical properties, making them suitable for entirely different applications.

H3: Carbon Structure and Stability

The product of torrefaction, often called biocoal, still contains a significant amount of its original volatile matter. Its carbon is not fully "fixed," making it an effective fuel but not a form of long-term sequestered carbon.

Biochar from pyrolysis has a much higher fixed carbon content. The high temperatures rearrange the carbon into stable, aromatic ring structures that are highly resistant to microbial decomposition. This stability is precisely what makes biochar an effective tool for long-term carbon sequestration in soil.

H3: Porosity and Surface Area

Torrefaction primarily densifies biomass, breaking down its fibrous structure. It does not create the intricate porous network characteristic of biochar.

Pyrolysis drives off volatile gases, leaving behind the carbon framework. This process creates a highly porous material with a vast internal surface area. This structure is critical for biochar's function in soil, allowing it to retain water and nutrients.

H3: Intended Application

The goal of torrefaction is to produce a high-energy-density, hydrophobic (water-repellent) solid fuel. It's designed to be easily pelletized and used for co-firing in coal power plants or for industrial heat.

The goal of creating biochar via pyrolysis is primarily for non-fuel applications. Its primary value lies in its use as a soil amendment to improve soil health, water retention, and nutrient cycling, or as a filtration medium.

Understanding the Trade-offs and Process Outputs

The choice between the two is a strategic decision based on desired outputs and economics.

H3: Solid Yield

Torrefaction is optimized for solid product yield. Because less of the biomass is driven off as gas and liquid, the mass yield of torrefied material is high, typically 70-80% of the original dry biomass.

Pyrolysis has a much lower solid yield. A typical biochar-optimized process might yield only 25-35% solid biochar by mass, with the rest converted into bio-oil and syngas.

H3: Co-products

Torrefaction produces a limited amount of acidic water and some combustible gases (tor-gas), which are almost always used internally to provide heat for the process. It is essentially a single-product system.

Pyrolysis is inherently a multi-product platform. The bio-oil and syngas are valuable co-products that can be used to generate energy or refined into other chemicals, creating separate revenue streams.

Making the Right Choice for Your Goal

The choice between these processes is dictated entirely by your end goal.

- If your primary focus is creating a dense, water-repellent solid fuel to replace coal: Torrefaction is the more direct and higher-yield process for this specific application.

- If your primary focus is long-term carbon sequestration and soil amendment: Pyrolysis is the only process that produces true, stable, and porous biochar suitable for agricultural and environmental use.

- If your primary focus is producing bio-oil or a spectrum of valuable co-products: Pyrolysis is the required pathway, with biochar being an important part of the overall system value.

Ultimately, understanding this core distinction between "upgrading a fuel" and "transforming a material" is the key to selecting the correct thermal technology for your needs.

Summary Table:

| Feature | Torrefaction | Pyrolysis Biochar |

|---|---|---|

| Primary Goal | Create a dense, coal-like solid fuel | Produce a stable, carbon-rich soil amendment (biochar) |

| Temperature Range | 200-300°C (392-572°F) | >350°C, often up to 700°C (662-1292°F) |

| Oxygen Environment | Oxygen-limited | Near-total absence of oxygen (anaerobic) |

| Solid Product | Biocoal (high in volatiles) | Biochar (high in stable, fixed carbon) |

| Solid Yield | High (70-80%) | Lower (25-35%) |

| Key Application | Solid fuel replacement for coal | Soil amendment, carbon sequestration, filtration |

| Co-products | Limited (used for process heat) | Bio-oil and syngas (valuable co-products) |

Ready to select the right thermal processing equipment for your biomass goals?

Whether your project requires the precise temperature control of a pyrolysis reactor or the robust design of a torrefaction unit, KINTEK has the expertise and equipment to support your success. Our specialized lab equipment and consumables are designed to meet the demanding needs of biomass research and development.

Contact our experts today to discuss how our solutions can help you achieve superior results in biochar production, fuel upgrading, or process optimization.

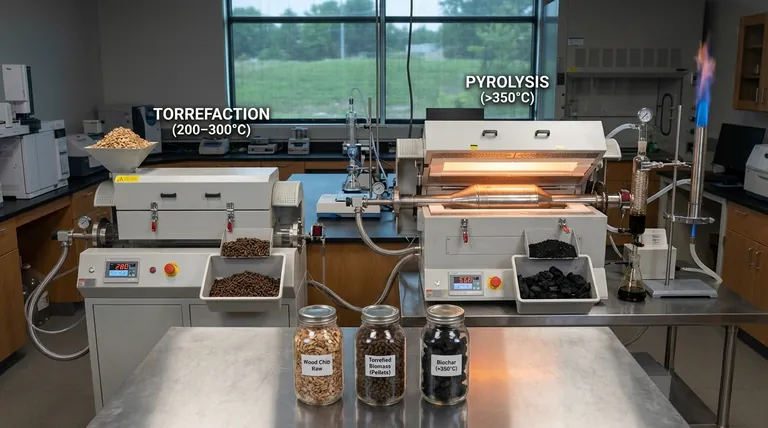

Visual Guide

Related Products

- Rotary Tube Furnace Split Multi Heating Zone Rotating Tube Furnace

- Vacuum Sealed Continuous Working Rotary Tube Furnace Rotating Tube Furnace

- Laboratory Vacuum Tilt Rotary Tube Furnace Rotating Tube Furnace

- Laboratory Rapid Thermal Processing (RTP) Quartz Tube Furnace

- 1400℃ Laboratory High Temperature Tube Furnace with Alumina Tube

People Also Ask

- What is a rotary heat type furnace? The Ultimate Guide to Uniform Heating & Mixing

- What is the process of zirconium production? From Ore to High-Performance Metal & Ceramic

- How are tube furnaces classified based on the orientation of the tube? Choose the Right Design for Your Process

- How do tube furnaces or muffle furnaces ensure stoichiometric accuracy during synthesis? Mastering Li4GeO4 & Li4VO4

- At what temperature does wood pyrolysis begin? Control the Process for Biochar, Bio-Oil, or Syngas