While the term "vacuum packing" often refers to food storage, in an industrial metalworking context, it almost certainly refers to vacuum hardening. The core difference is that vacuum hardening removes all air from a sealed chamber before heating the metal, whereas normal hardening heats the metal in the presence of an atmosphere. This fundamental change in environment leads to significant differences in cost, material compatibility, and the final quality of the component.

The decision between vacuum and normal hardening is not just about making metal harder. It is a strategic choice that balances the higher cost of vacuum processing against the critical need for a pristine surface finish, minimal distortion, and predictable material properties.

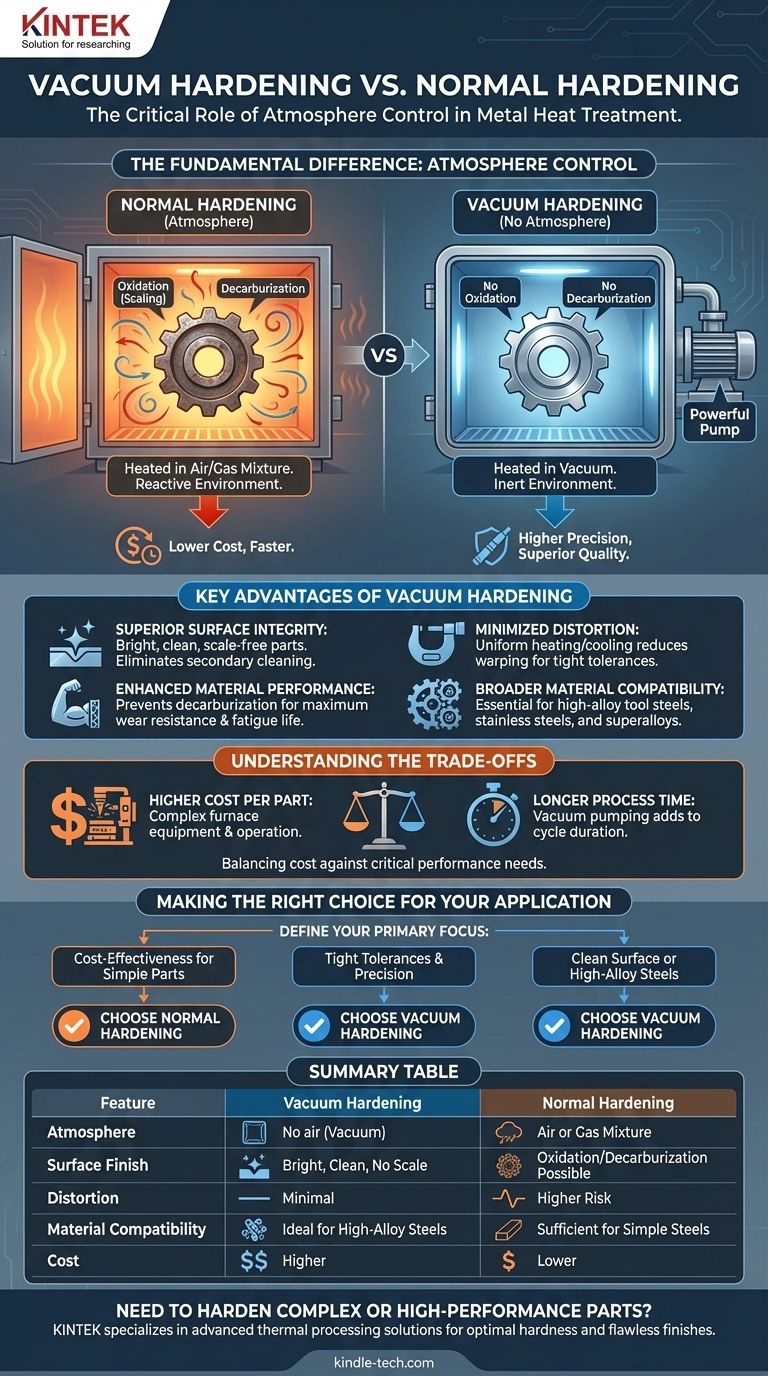

The Fundamental Difference: Atmosphere Control

The key distinction between these two heat treatment methods lies in what surrounds the metal part as it is heated and cooled. This environment directly impacts the surface of the component.

Normal Hardening: Heating in an Atmosphere

Normal, or conventional, hardening involves heating a metal part in a furnace that contains air or a controlled mixture of gases.

This direct exposure to the atmosphere at high temperatures can cause unwanted chemical reactions. The most common issues are oxidation (scaling) and decarburization (the loss of carbon from the surface), which can soften the steel.

Vacuum Hardening: Heating in an Absense of Atmosphere

Vacuum hardening places the part inside a sealed, robust chamber. Powerful pumps then remove virtually all of the air before the heating cycle begins.

By heating the material in a vacuum, there is no oxygen or other reactive gas to interact with the metal's surface. This completely prevents oxidation and decarburization, resulting in a part that is chemically unchanged on its surface.

Key Advantages of Vacuum Hardening

Choosing the more complex vacuum process provides distinct engineering advantages that are critical for high-performance and high-precision applications.

Superior Surface Integrity

Parts that emerge from a vacuum furnace are bright, clean, and free of scale. This often eliminates the need for secondary operations like sandblasting, chemical cleaning, or grinding to remove a damaged surface layer.

Minimized Distortion

Vacuum furnaces allow for extremely precise control over heating and cooling rates. This uniform, controlled processing minimizes the internal stresses that cause parts to warp or distort, which is essential for complex geometries and tight tolerances.

Enhanced Material Performance

By preventing decarburization, vacuum hardening ensures that the surface of the part achieves the same full hardness as the core. This is critical for components that require maximum wear resistance and fatigue life.

Broader Material Compatibility

Many high-alloy tool steels, stainless steels, and superalloys are highly sensitive to atmospheric heating. The inert environment of a vacuum furnace is the only way to properly harden these advanced materials without compromising their integrity.

Understanding the Trade-offs

Despite its benefits, vacuum hardening is not always the necessary or most economical choice. Understanding its limitations is key to making an informed decision.

The Cost Factor

Vacuum furnaces are complex machines that are significantly more expensive to build, operate, and maintain than conventional atmospheric furnaces. This translates directly to a higher cost per part.

Process Time and Batch Size

The time required to pump the chamber down to a deep vacuum adds to the total cycle time. This can make the process slower than some conventional methods, particularly for large production runs.

When Normal Hardening is Sufficient

For simple, low-carbon steel parts where the final surface finish is not critical or where subsequent machining will occur anyway, normal hardening is often perfectly adequate. It provides the necessary hardness at a much lower cost.

Making the Right Choice for Your Application

Selecting the correct hardening process requires you to define the most important outcome for your specific component.

- If your primary focus is cost-effectiveness for simple parts: Normal atmospheric hardening is almost always the most economical and sufficient choice.

- If your primary focus is maintaining tight tolerances on complex parts: Vacuum hardening is essential to minimize distortion and avoid costly rework.

- If your primary focus is a clean, ready-to-use surface finish: Vacuum hardening delivers a bright, scale-free part that requires no secondary cleaning.

- If your primary focus is hardening high-alloy or specialty steels: Vacuum hardening is not just an option but a requirement to preserve the material's properties.

Ultimately, your choice is an investment in the final quality and performance required for your component.

Summary Table:

| Feature | Vacuum Hardening | Normal Hardening |

|---|---|---|

| Atmosphere | No air (vacuum) | Air or gas mixture |

| Surface Finish | Bright, clean, no scale | Oxidation/decarburization possible |

| Distortion | Minimal | Higher risk |

| Material Compatibility | Ideal for high-alloy steels | Sufficient for simple steels |

| Cost | Higher | Lower |

Need to Harden Complex or High-Performance Metal Parts?

Choosing the right heat treatment process is critical for your component's success. The precision and superior surface integrity of vacuum hardening can be the difference between a part that meets specifications and one that fails.

KINTEK specializes in advanced thermal processing solutions, including vacuum hardening, for laboratories and manufacturers requiring the highest quality results. Our expertise ensures your high-alloy steels, tool steels, and precision components achieve optimal hardness, minimal distortion, and a flawless finish.

Let's discuss your project requirements and find the most effective hardening solution for your needs.

Contact our experts today to get started!

Visual Guide

Related Products

- Vacuum Heat Treat Furnace with Ceramic Fiber Liner

- Vacuum Heat Treat Furnace and Levitation Induction Melting Furnace

- Vacuum Heat Treat Sintering Brazing Furnace

- Vacuum Heat Treat and Molybdenum Wire Sintering Furnace for Vacuum Sintering

- Molybdenum Vacuum Heat Treat Furnace

People Also Ask

- Why do you vacuum for heat treatment? Achieve Flawless, High-Performance Metal Components

- What is the structure of a vacuum furnace? A Guide to Its Core Components & Functions

- How does argon and nitrogen cooling compare in vacuum furnaces? A Guide to Faster, Cheaper Quenching

- What is the leak rate for a vacuum furnace? Ensure Process Purity and Repeatability

- What does a vacuum furnace do? Achieve High-Purity Heat Treatment for Superior Components