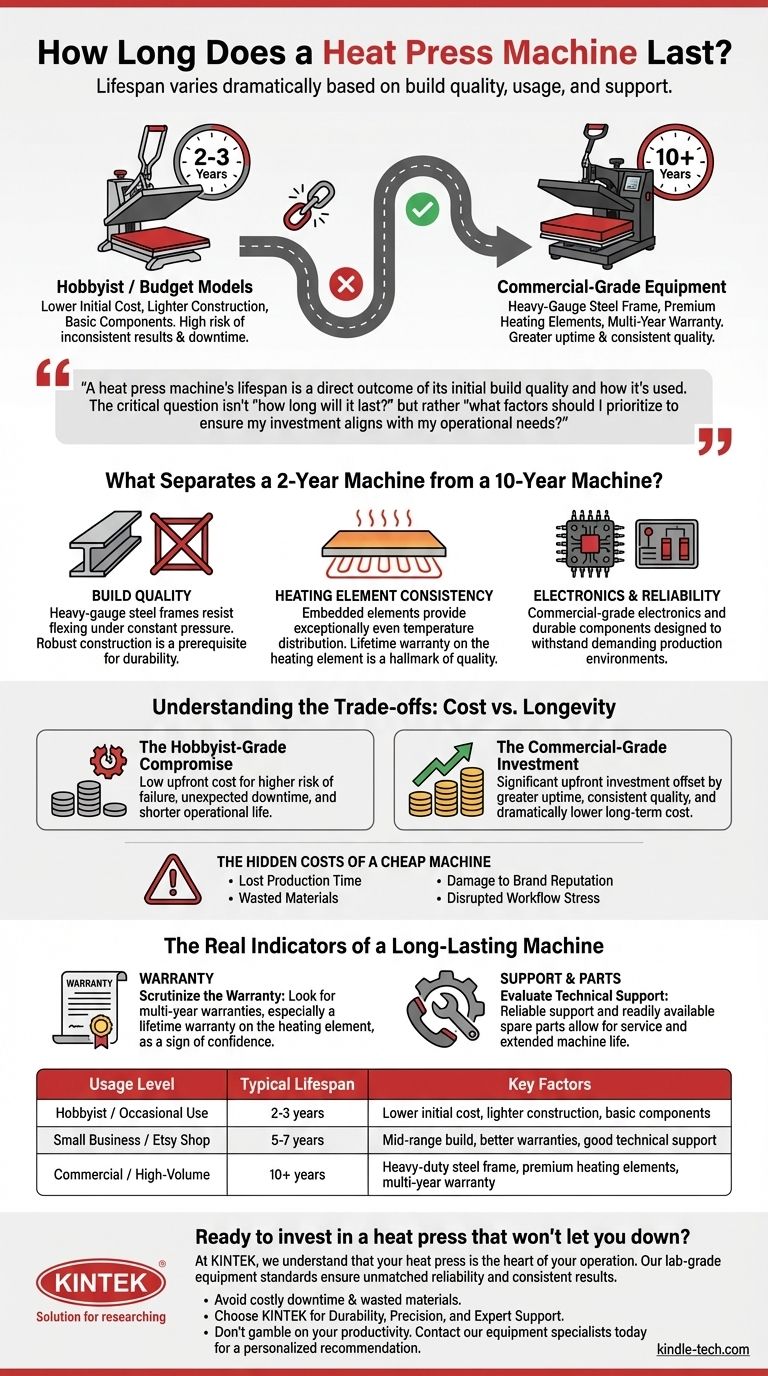

The lifespan of a heat press machine varies dramatically, from just a couple of years for budget-friendly hobby models to over a decade for robust commercial-grade equipment. The longevity is not a fixed number but is determined almost entirely by the machine's build quality, the intensity of its use, and the availability of support and spare parts.

A heat press machine's lifespan is a direct outcome of its initial build quality and how it's used. The critical question isn't "how long will it last?" but rather "what factors should I prioritize to ensure my investment aligns with my operational needs?"

What Separates a 2-Year Machine from a 10-Year Machine?

The difference in lifespan comes down to fundamental choices in engineering, materials, and design philosophy. A machine built for daily commercial use is fundamentally different from one intended for occasional hobby use.

The Critical Role of Build Quality

A long-lasting machine starts with a solid foundation. Look for heavy-gauge steel frames that resist flexing and warping under the constant pressure and heat cycles.

This is the difference between a commercial oven built to run 12 hours a day and a home oven built for occasional use. The commercial unit's robust construction is a prerequisite for durability.

Heating Element Consistency

The heart of the heat press is its heating element. In cheaper models, elements can degrade, creating cold spots that ruin transfers and render the machine useless.

High-quality machines feature platens with embedded heating elements that provide exceptionally even temperature distribution. The manufacturer's warranty on the heating element is often the single best indicator of its quality.

Electronics and Component Reliability

Beyond the frame and platen, the controller, wiring, and pressure mechanisms are common points of failure.

Commercial-grade machines use higher-quality electronics and more durable components designed to withstand the stress of a demanding production environment.

Understanding the Trade-offs: Cost vs. Longevity

Choosing a heat press involves a direct trade-off between the initial purchase price and the long-term total cost of ownership. Understanding this is crucial for making a sound investment.

The Hobbyist-Grade Compromise

Low-cost machines are appealing for their accessibility. They allow you to enter the market with minimal financial risk.

However, they are not built for extensive use. You are trading a low upfront cost for a higher risk of inconsistent results, unexpected downtime, and a much shorter operational life.

The Commercial-Grade Investment

A commercial-grade machine represents a significant upfront investment. Its price reflects the durable materials and superior engineering required for reliability under pressure.

For any serious business, this higher cost is offset by greater uptime, consistent quality, and a dramatically lower long-term cost when you factor in replacing cheaper units every few years.

The Hidden Costs of a Cheap Machine

A failed heat press doesn't just cost money to replace. The true cost includes lost production time, wasted materials from failed transfers, damage to your brand's reputation, and the stress of a disrupted workflow.

The Real Indicators of a Long-Lasting Machine

Instead of focusing on a specific number of years, evaluate the factors that signal a machine is built to last.

Scrutinize the Warranty

A manufacturer's warranty is their statement of confidence. A short, 90-day or 1-year warranty suggests a product built to a price point, not for endurance.

Look for machines with multi-year warranties, and pay special attention to a lifetime warranty on the heating element. This is a hallmark of a top-tier brand.

Evaluate Technical Support and Parts

As the reference material wisely notes, durability is also about serviceability. When a component eventually fails, can you get help?

A brand that offers reliable technical support and makes spare parts available allows you to service and extend the life of your machine for many years, whereas a failure on a no-name import often means replacing the entire unit.

Making the Right Choice for Your Goal

Your final decision should be guided by a clear understanding of your own objectives.

- If your primary focus is starting a hobby or occasional personal projects: A reputable entry-level machine is a low-risk starting point, but be prepared to upgrade if your usage increases.

- If your primary focus is launching a small business or Etsy shop: Invest in a mid-range or "prosumer" model from a brand with a strong warranty and positive reviews to protect your business from costly downtime.

- If your primary focus is running a high-volume commercial operation: Prioritize a heavy-duty, commercial-grade machine from a brand known for its durability and excellent technical support; the upfront cost is an investment in operational certainty.

Ultimately, choosing a heat press is an investment in the reliability and continuity of your work.

Summary Table:

| Usage Level | Typical Lifespan | Key Factors |

|---|---|---|

| Hobbyist / Occasional Use | 2-3 years | Lower initial cost, lighter construction, basic components |

| Small Business / Etsy Shop | 5-7 years | Mid-range build, better warranties, good technical support |

| Commercial / High-Volume | 10+ years | Heavy-duty steel frame, premium heating elements, multi-year warranty |

Ready to invest in a heat press that won't let you down?

At KINTEK, we understand that your heat press is the heart of your operation. Whether you're a hobbyist starting a new project or a commercial printer running high-volume jobs, our lab-grade equipment standards ensure unmatched reliability and consistent results.

We help you avoid:

- Costly downtime from machine failures

- Wasted materials from inconsistent heating

- The stress of replacing cheap equipment every few years

Choose KINTEK for:

- Durability: Heavy-gauge steel frames and industrial-grade components built for daily use.

- Precision: Even heat distribution technology for perfect transfers every time.

- Support: Expert technical support and readily available spare parts to extend your machine's life.

Don't gamble on your productivity. Contact our equipment specialists today for a personalized recommendation that matches your needs and budget. Let's build a reliable foundation for your success together!

Visual Guide

Related Products

- Automatic Laboratory Heat Press Machine

- 24T 30T 60T Heated Hydraulic Press Machine with Heated Plates for Laboratory Hot Press

- Double Plate Heating Press Mold for Lab

- Automatic Heated Hydraulic Press Machine with Heated Plates for Laboratory Hot Press

- Manual High Temperature Heated Hydraulic Press Machine with Heated Plates for Lab

People Also Ask

- What is the hot pressing process polymer? Achieve Maximum Density and Strength for Critical Parts

- What is hot press vs cold press machine? Choose the Right Method for Your Materials

- Why is a laboratory precision hot press necessary for processing high-performance composite solid-state electrolyte membranes?

- How do laboratory hydraulic presses and hot pressing affect MEA preparation? Optimize Your Fuel Cell Efficiency

- How is pressure generated and applied in a hot press? Master High-Intensity Hydraulic & Pneumatic Systems

- What is the mechanism of a precision hydraulic hot press for MEA fabrication? Master Decal Transfer Success

- What is the core function of a laboratory heated hydraulic press in CSP? Revolutionize Low-Temp Ceramic Sintering

- What is the primary purpose of using the Hot Press process for Thallium Bromide? Achieve High-Performance TlBr Crystals