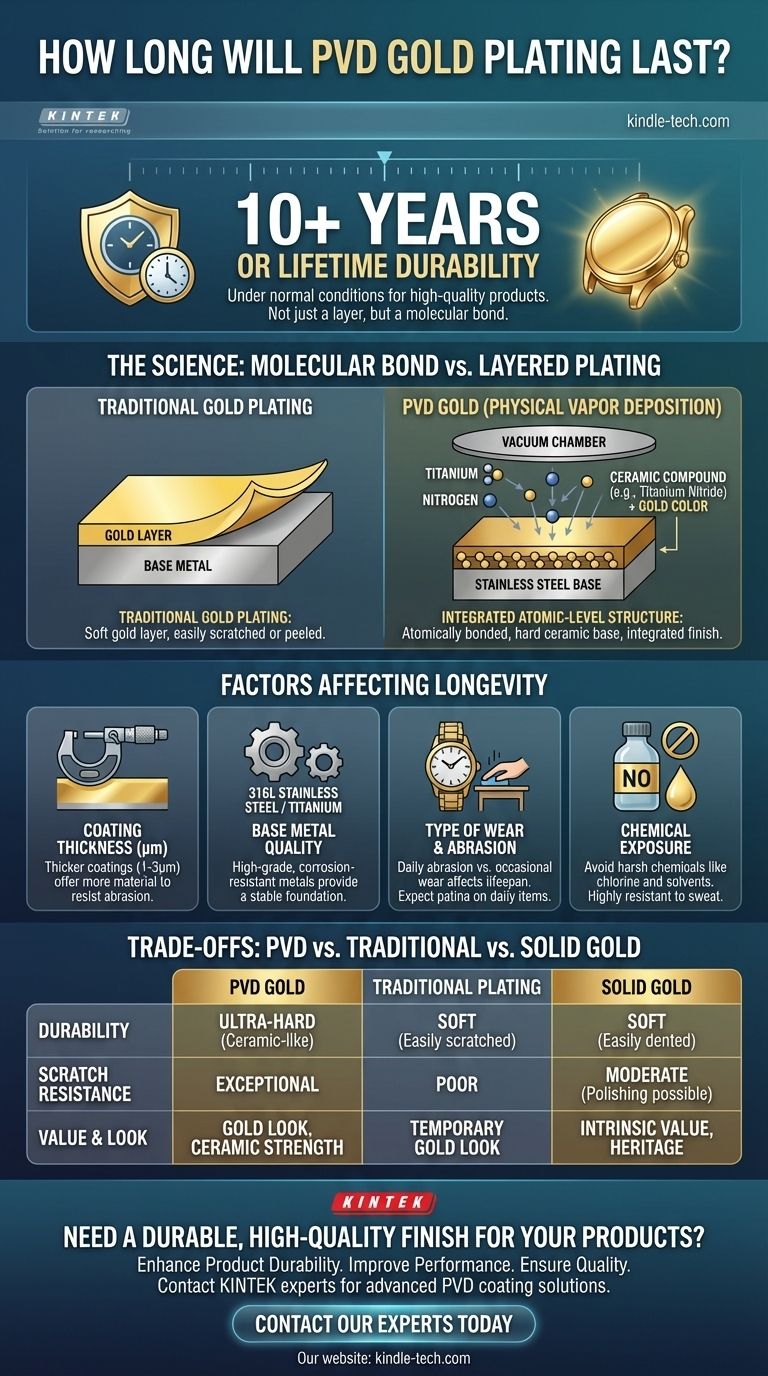

For a high-quality product, PVD gold plating can last for ten years or more, and will often last for the lifetime of the item under normal conditions. This exceptional durability stems from a process that is fundamentally different and far more robust than traditional gold plating. The longevity depends on the thickness of the coating, the materials used, and how the item is worn and cared for.

The crucial insight is that the durability of a "PVD gold" finish does not come from the gold, but from an underlying, ultra-hard ceramic compound (like titanium nitride) that is molecularly bonded to the base metal. The gold is merely a component that provides color, while the PVD process itself provides the strength.

What is PVD Gold, and Why Is It So Durable?

To understand its longevity, you must first understand that PVD is not plating in the traditional sense. It's a high-tech vacuum deposition process that creates a finish far superior to older methods.

The PVD Process Explained

PVD, or Physical Vapor Deposition, takes place in a high-vacuum chamber. A solid target material, such as titanium, is vaporized by a plasma arc into its atomic components. These atoms, along with a reactive gas like nitrogen, are then deposited onto the product (e.g., a stainless steel watch case), forming a new, atomically-bonded surface layer.

The Secret is the Ceramic Base

The "gold" color in high-end PVD is typically achieved using titanium nitride (TiN) or zirconium nitride (ZrN). These are extremely hard ceramic materials, often used to coat industrial cutting tools to increase their lifespan. The final color is fine-tuned by precisely adjusting the mixture of gases and metals in the chamber.

It's a Molecular Bond, Not a Layer

Unlike traditional electroplating, which lays a soft layer of gold on top of a metal, PVD integrates the new material into the surface of the base metal. This molecular bond means the finish is not a separate layer that can easily flake or peel off. It is, for all practical purposes, part of the object itself.

The Factors That Determine Longevity

Not all PVD coatings are created equal. Several key factors directly influence how long the finish will maintain its appearance.

Coating Thickness

PVD coatings are measured in microns (µm). While even a thin PVD coating is durable, a thicker coating (e.g., 1-3 microns) will naturally offer more material to withstand abrasion over many years of wear.

Quality of the Base Metal

The process works best on high-grade, corrosion-resistant metals. 316L stainless steel and titanium are ideal substrates for PVD coating, as they provide a stable and durable foundation for the finish to bond to.

Type of Wear and Abrasion

An item's lifespan is dictated by its use. A watch clasp that constantly rubs against a desk will show wear faster than the bezel. An occasional-wear dress watch may look new for decades, while a daily-wear tool watch will develop a patina.

Exposure to Chemicals

While highly resistant to sweat and corrosion, the finish can be damaged by prolonged exposure to harsh chemicals. Chlorine from swimming pools, solvents, and abrasive cleaners should be avoided.

Understanding the Trade-offs

PVD offers incredible performance, but it's important to understand its position relative to other options.

PVD vs. Traditional Gold Plating

This is not a fair comparison. Traditional electroplating deposits a very thin, soft layer of pure gold that can often be scratched off with a fingernail. PVD is orders of magnitude harder, more scratch-resistant, and more corrosion-resistant.

PVD vs. Solid Gold

This is the most critical trade-off. PVD provides the look of gold with the durability of a ceramic tool bit. Solid gold, while intrinsically valuable, is a very soft metal that scratches and dents easily.

A deep scratch on a PVD-coated item can, in theory, reveal the silver-colored steel underneath, and it cannot be polished away. However, the force required to create such a scratch is significantly greater than what would dent or gouge a solid gold item.

Making the Right Choice for Your Goal

To select the right material, you must be clear about your priority.

- If your primary focus is maximum durability and a gold appearance: High-quality PVD on a stainless steel base is the most resilient and practical choice for daily-wear items.

- If your primary focus is intrinsic value and heritage: Solid gold is the only option, but you must accept its inherent softness and the need for careful wear.

- If your primary focus is a temporary fashion look on a tight budget: Traditional gold plating may suffice, but you must expect the finish to wear away with regular use.

By understanding the science behind the finish, you can confidently choose the material that best aligns with your expectations for longevity and value.

Summary Table:

| Factor | Impact on Longevity | Key Insight |

|---|---|---|

| Coating Thickness | Higher thickness (1-3µm) = More durability | More material to resist abrasion over time. |

| Base Metal Quality | 316L Stainless Steel or Titanium = Best results | Provides a stable, corrosion-resistant foundation. |

| Type of Wear | Daily abrasion vs. occasional wear affects lifespan | A daily-wear item will develop a patina faster. |

| Exposure to Chemicals | Harsh chemicals (e.g., chlorine) can damage the finish | Highly resistant to sweat, but avoid harsh cleaners. |

Need a Durable, High-Quality Finish for Your Products?

At KINTEK, we specialize in advanced PVD coating solutions for laboratory and industrial equipment. Our expertise ensures your components benefit from ultra-hard, molecularly-bonded coatings that offer exceptional scratch and corrosion resistance, significantly extending product life.

We help you:

- Enhance Product Durability: Achieve long-lasting finishes that withstand daily wear and tear.

- Improve Performance: Utilize coatings that are proven in demanding industrial applications.

- Ensure Quality: Rely on our precision processes for consistent, high-quality results.

Let's discuss how our PVD coatings can add value and longevity to your products. Contact our experts today for a tailored solution!

Visual Guide

Related Products

- HFCVD Machine System Equipment for Drawing Die Nano-Diamond Coating

- Vacuum Hot Press Furnace Machine for Lamination and Heating

- 915MHz MPCVD Diamond Machine Microwave Plasma Chemical Vapor Deposition System Reactor

- Laboratory Sterilizer Lab Autoclave Pulse Vacuum Lifting Sterilizer

- CVD Diamond Cutting Tool Blanks for Precision Machining

People Also Ask

- What is the hot filament chemical vapour deposition of diamond? A Guide to Synthetic Diamond Coating

- How is diamond coating made? A Guide to CVD and PVD Methods

- What is microwave plasma CVD? A Guide to High-Purity Diamond and Material Synthesis

- What is direct current DC magnetron sputtering? A Guide to High-Quality Thin Film Deposition

- What is the process of coating deposition? A Step-by-Step Guide to Thin Film Engineering