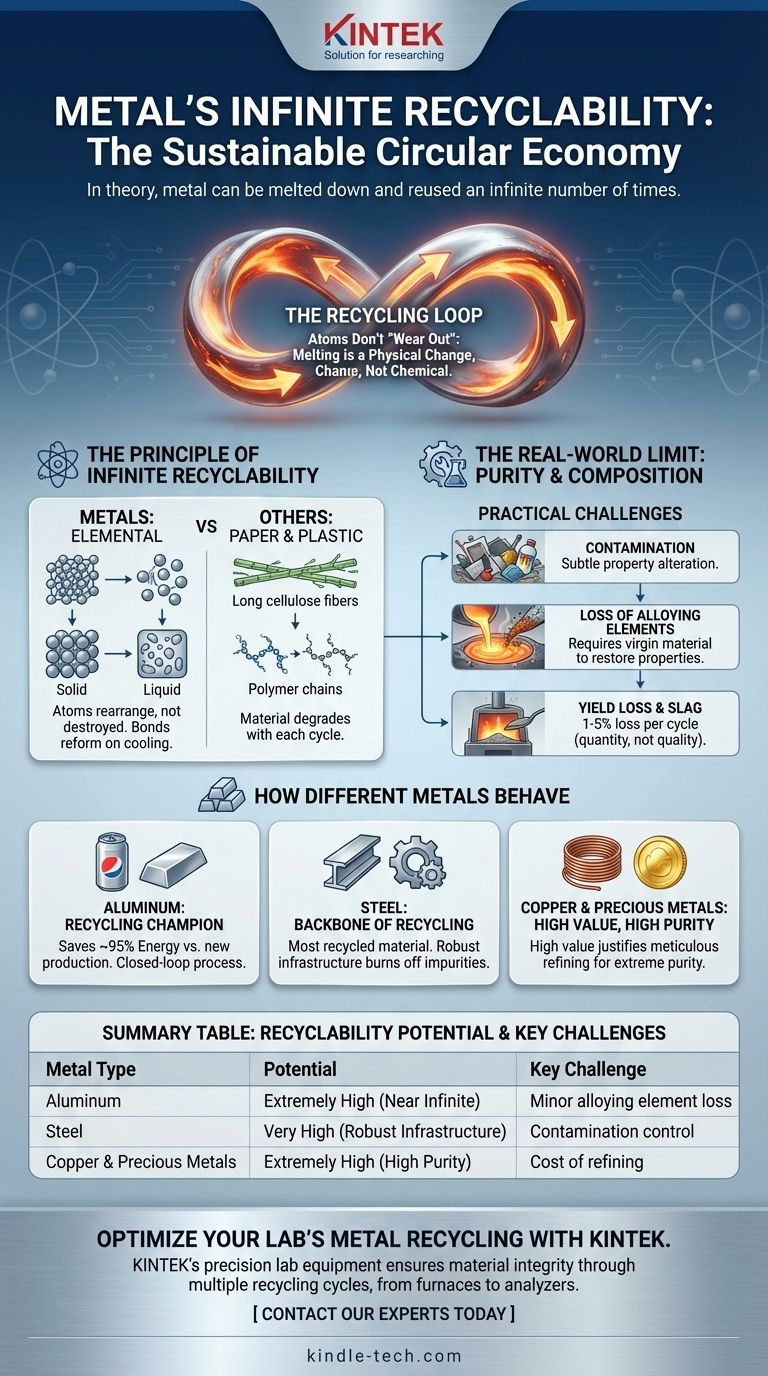

In theory, metal can be melted down and reused an infinite number of times. Unlike materials such as paper or plastic, the fundamental atomic structure of a metal is not degraded by the melting process. This unique property makes metals like aluminum, steel, and copper cornerstones of the circular economy, as their core atoms don't "wear out."

The number of times a metal can be recycled is not limited by the metal itself, but by the practical challenges of maintaining its purity and specific chemical composition with each successive cycle. The problem isn't the material, but the process.

The Principle of Infinite Recyclability

To understand why metals are unique, we must look at them on an atomic level. This reveals why they are fundamentally different from other common recyclable materials.

### Metals are Elemental

Metals are elements, the basic building blocks of matter. When you melt a piece of aluminum, you are not destroying the aluminum atoms; you are simply breaking the metallic bonds holding them together in a solid state.

Upon cooling, these bonds reform, and the material becomes a solid again with its essential properties intact. The atoms themselves do not get "old" or "worn out."

### A Physical, Not Chemical, Transformation

Melting is a physical change, not a chemical one. This distinction is critical. The process rearranges the atoms from a rigid lattice (solid) to a disordered state (liquid), but it does not alter the atoms themselves.

### Contrasting with Other Materials

This contrasts sharply with materials like paper or plastic. Recycling paper shortens its cellulose fibers, reducing its strength with each cycle. Recycling plastic often breaks down the long polymer chains, a form of chemical degradation that diminishes its quality.

The Real-World Limit: Purity and Composition

While the theory is infinite, the practical application of metal recycling faces hurdles that introduce limitations. The primary challenges are contamination and maintaining the precise "recipe" of metal alloys.

### The Problem of Contamination

Scrap metal is rarely pure. It often comes mixed with other metals, paint, plastics, and other non-metallic elements. While the smelting process is designed to remove many of these impurities, some can remain.

This contamination can subtly alter the properties of the final product, potentially making it unsuitable for high-performance applications like aerospace components.

### The Loss of Alloying Elements

Most metals we use are not pure elements but alloys—metals mixed with other elements to achieve specific properties like strength, corrosion resistance, or lightness. For example, steel is an iron-carbon alloy, and aircraft-grade aluminum contains elements like zinc and magnesium.

During melting, some of these crucial alloying elements can oxidize and be lost to the slag (the molten layer of impurities skimmed off the top). To bring the recycled metal back to its original specification, new, "virgin" material or pure alloying elements must be added.

### Yield Loss and Slag

Not all of the metal that enters the furnace comes out as a usable product. A certain percentage is inevitably lost as dross or slag during the melting and refining process.

While this loss is typically small for each cycle (often 1-5%), it represents a practical limit on the efficiency of the recycling loop. It is a loss of quantity, not quality.

How Different Metals Behave

Different metals have unique properties that affect their recyclability in practice.

### Aluminum: The Recycling Champion

Aluminum is famous for its recyclability. Recycling aluminum saves up to 95% of the energy required to produce it from its raw ore, bauxite. The process is so efficient that the quality of recycled aluminum is virtually indistinguishable from primary aluminum, making it a true "closed-loop" material.

### Steel: The Backbone of Recycling

As the most recycled material on Earth, steel's recycling infrastructure is incredibly robust. The high temperatures of steel furnaces can burn off many impurities, and the chemistry is well-understood, allowing recyclers to precisely control the final composition.

### Copper and Precious Metals: High Value, High Purity

Metals like copper, gold, and silver have high intrinsic value, which justifies more meticulous and expensive refining processes. This ensures that they can be recycled repeatedly while maintaining extremely high levels of purity.

How to Apply This to Your Goal

Understanding the nuance between theoretical perfection and practical limits allows you to make better decisions depending on your objective.

- If your primary focus is environmental sustainability: Using recycled metal is almost always the superior choice due to the massive energy savings and reduction in mining.

- If your primary focus is high-performance engineering (e.g., aerospace): You must account for the strict need for purity and precise alloy composition, which may require blending recycled material with virgin material to meet exacting standards.

- If your primary focus is general consumer or industrial products: The vast majority of these goods can and should be made from recycled metal without any compromise in quality or performance.

This inherent and endlessly repeatable quality makes metal a cornerstone material for building a truly sustainable and circular economy.

Summary Table:

| Metal Type | Recyclability Potential | Key Challenge |

|---|---|---|

| Aluminum | Extremely High (Near Infinite) | Minor alloying element loss |

| Steel | Very High (Robust Infrastructure) | Contamination control |

| Copper & Precious Metals | Extremely High (High Purity) | Cost of refining |

Optimize your lab's metal recycling and material testing processes with KINTEK.

Whether you're developing sustainable materials or ensuring the purity of metal alloys for high-performance applications, KINTEK's precision lab equipment and consumables are essential for your success. Our furnaces, analyzers, and sample preparation tools help you maintain material integrity through multiple recycling cycles.

Contact our experts today to discuss how KINTEK can support your laboratory's specific metal testing and recycling needs!

Visual Guide

Related Products

- Electric Rotary Kiln Pyrolysis Furnace Plant Machine Calciner Small Rotary Kiln Rotating Furnace

- Vacuum Sealed Continuous Working Rotary Tube Furnace Rotating Tube Furnace

- Electric Rotary Kiln Continuous Working Small Rotary Furnace Heating Pyrolysis Plant

- Electric Rotary Kiln Small Rotary Furnace Biomass Pyrolysis Plant

- Electric Rotary Kiln Small Rotary Furnace for Activated Carbon Regeneration

People Also Ask

- What are the different types of induction heating? Choose the Right System for Your Melting & Heat Treating Needs

- What are the materials for acid lining and basic lining in electric induction furnace? Choose the Right Refractory for Your Melt

- What is melt loss? The Ultimate Guide to Reducing Metal Loss in High-Temp Processing

- What is the function of the electric arc vacuum chamber in the ITT process? Single-Step Titanium Powder Production

- What is the primary function of a Vacuum Induction Melting Furnace? Achieving Pure Cu-Si Alloy Synthesis

- What is the advantage of induction furnace? Achieve Clean, Precise, and Efficient Metal Melting

- What is the frequency of induction melting furnace? Optimize Your Melting Process with the Right Frequency

- Why does an induction furnace blast? Prevent Catastrophic Steam Explosions in Your Foundry