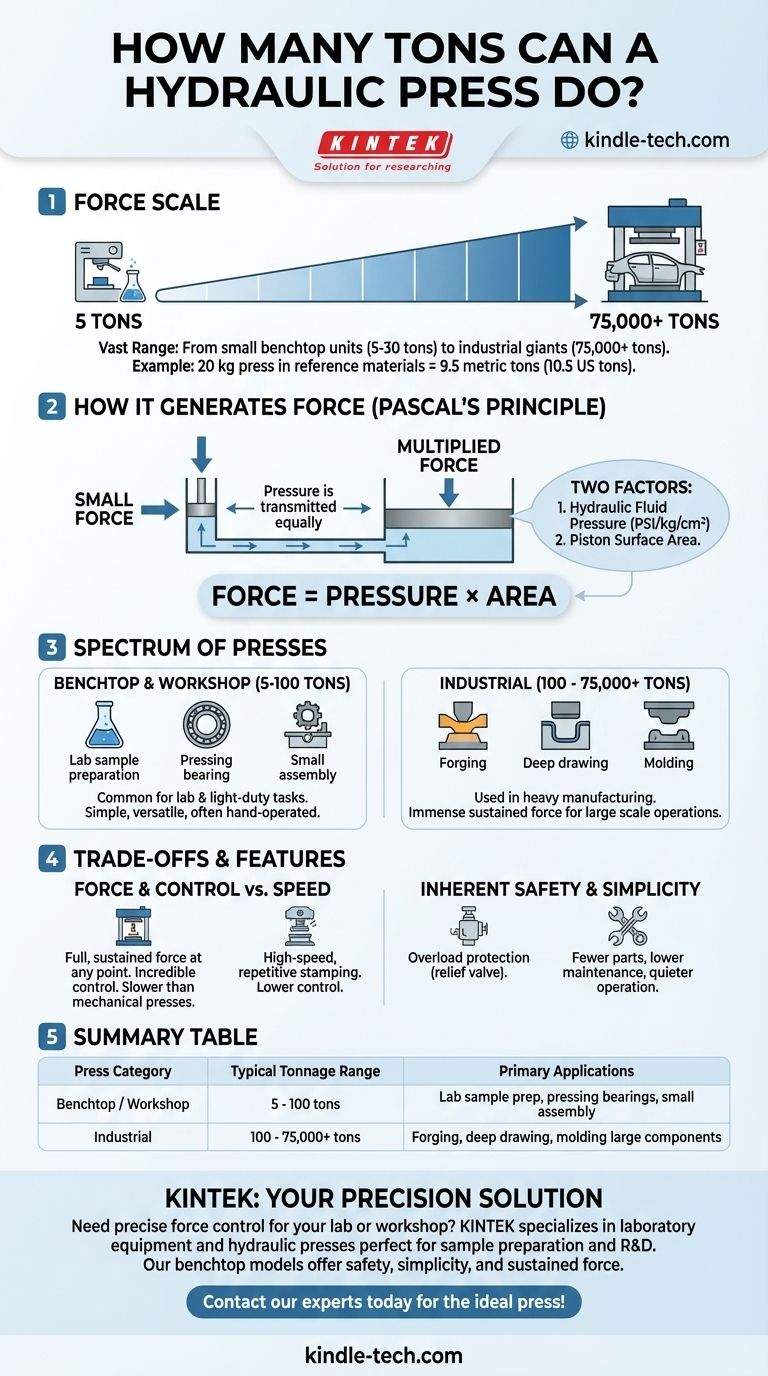

The force a hydraulic press can exert is not a single number but a vast range, scaling from small benchtop units generating 5-30 tons to massive industrial machines capable of producing over 75,000 tons. The specific 20 kg press in your reference materials, for example, has a recommended maximum power of 9.5 metric tons (about 10.5 US tons), which is typical for laboratory or small workshop applications.

A hydraulic press is a force multiplier. Its tonnage is not a fixed property but a direct result of its design, specifically the hydraulic pressure and the piston size, allowing for an immense range of capabilities from tabletop models to factory-sized giants.

How a Hydraulic Press Generates Force

A hydraulic press operates on a fundamental law of physics known as Pascal's Principle. This principle is the key to understanding its capabilities.

The Core Concept: Pascal's Principle

Pascal's Principle states that pressure applied to an enclosed, incompressible fluid is transmitted equally throughout the fluid. A hydraulic press uses this to its advantage.

A small force is applied to a small piston, which creates pressure in the hydraulic fluid. This same pressure then acts on a much larger piston, and because Force = Pressure × Area, the larger surface area of the second piston multiplies the initial force enormously.

The Two Factors Defining Tonnage

Ultimately, the maximum tonnage of any hydraulic press is determined by two variables:

- Hydraulic Fluid Pressure: The maximum pressure the pump, hoses, and seals can safely sustain, often measured in pounds per square inch (PSI) or kg/cm².

- Piston Surface Area: The size of the main piston face that the pressurized fluid pushes against. A larger piston results in a higher potential force for the same pressure.

The Spectrum of Hydraulic Presses

The term "hydraulic press" covers an enormous range of equipment, each designed for a specific purpose.

Benchtop and Workshop Presses (5-100 Tons)

These are the most common types of presses. The 20 kg unit from the reference, with its ~10-ton capacity, fits squarely in this category.

They are primarily used for sample preparation in labs, pressing bearings, small assembly work, and light-duty shaping. Their design is simple, often with a hand-operated lever, making them versatile and relatively inexpensive.

Industrial Presses (100 - 75,000+ Tons)

At the other end of the spectrum are industrial giants used in heavy manufacturing. These machines are used for processes that require immense, sustained force.

Common applications include forging large metal billets, deep drawing sheet metal for car body panels, and molding composite materials. These presses can be several stories tall and are the backbone of modern heavy industry.

Understanding the Trade-offs

While capable of immense force, hydraulic presses have distinct characteristics and are not the right tool for every job.

Force and Control vs. Speed

The defining advantage of a hydraulic press is its ability to deliver full, sustained force at any point in its stroke. This gives the operator incredible control over the process.

The primary trade-off is speed. Hydraulic presses are generally slower than their mechanical counterparts, which use a flywheel and crank for rapid, repetitive motion. This makes mechanical presses better suited for high-volume stamping of small parts.

Inherent Safety and Simplicity

Hydraulic systems have a built-in form of overload protection. If the force required exceeds the system's maximum pressure rating, a relief valve opens, preventing damage to the machine or tooling.

They also have fewer moving parts than complex mechanical presses, leading to lower maintenance costs and quieter operation. This simplicity contributes to their long lifespan and adaptability.

Making the Right Choice for Your Goal

Selecting the right press depends entirely on the task at hand.

- If your primary focus is lab sample preparation or small workshop tasks: A benchtop hydraulic press in the 5 to 30-ton range offers excellent control and sufficient power.

- If your primary focus is high-speed, repetitive stamping: A mechanical press is likely the more efficient choice due to its faster cycle times.

- If your primary focus is forming large, complex, or tough materials: A high-tonnage hydraulic press is the industry standard for its ability to deliver immense and precisely controlled force.

Understanding that a press's power is a function of its design empowers you to look beyond a single number and evaluate the right tool for your specific application.

Summary Table:

| Press Category | Typical Tonnage Range | Primary Applications |

|---|---|---|

| Benchtop / Workshop | 5 - 100 tons | Lab sample prep, pressing bearings, small assembly |

| Industrial | 100 - 75,000+ tons | Forging, deep drawing, molding large components |

Need precise force control for your lab or workshop? KINTEK specializes in laboratory equipment, including hydraulic presses perfect for sample preparation and R&D. Our benchtop models offer the safety, simplicity, and sustained force you need for accurate results. Contact our experts today to find the ideal press for your specific application!

Visual Guide

Related Products

- Laboratory Hydraulic Press Split Electric Lab Pellet Press

- Automatic Laboratory Heat Press Machine

- Heated Hydraulic Press Machine with Integrated Manual Heated Plates for Lab Use

- Automatic Heated Hydraulic Press Machine with Heated Plates for Laboratory Hot Press

- Manual Heated Hydraulic Press Machine with Heated Plates for Laboratory Hot Press

People Also Ask

- How does pressure control of a laboratory hydraulic press affect W-Ti alloys? Optimize Grain Structure & Density

- Who uses a hydraulic press? A Guide to Industries and Applications Requiring Massive Force

- What is the history of the hydraulic press? From Pascal's Principle to Industrial Revolution Powerhouse

- What are the components of a plate and frame filter press? A Detailed Breakdown of the 4 Key Systems

- Where is compression moulding used? For High-Strength Parts in Automotive, Aerospace & Electrical

- How much psi can a hydraulic press make? From 2,000 PSI to over 50,000 PSI Explained

- Can XRF detect rare earth elements? A Guide to Rapid, Non-Destructive Analysis

- What is the importance of using a laboratory hydraulic press for R1/3Zr2(PO4)3 samples? Enhance Ion Conductivity