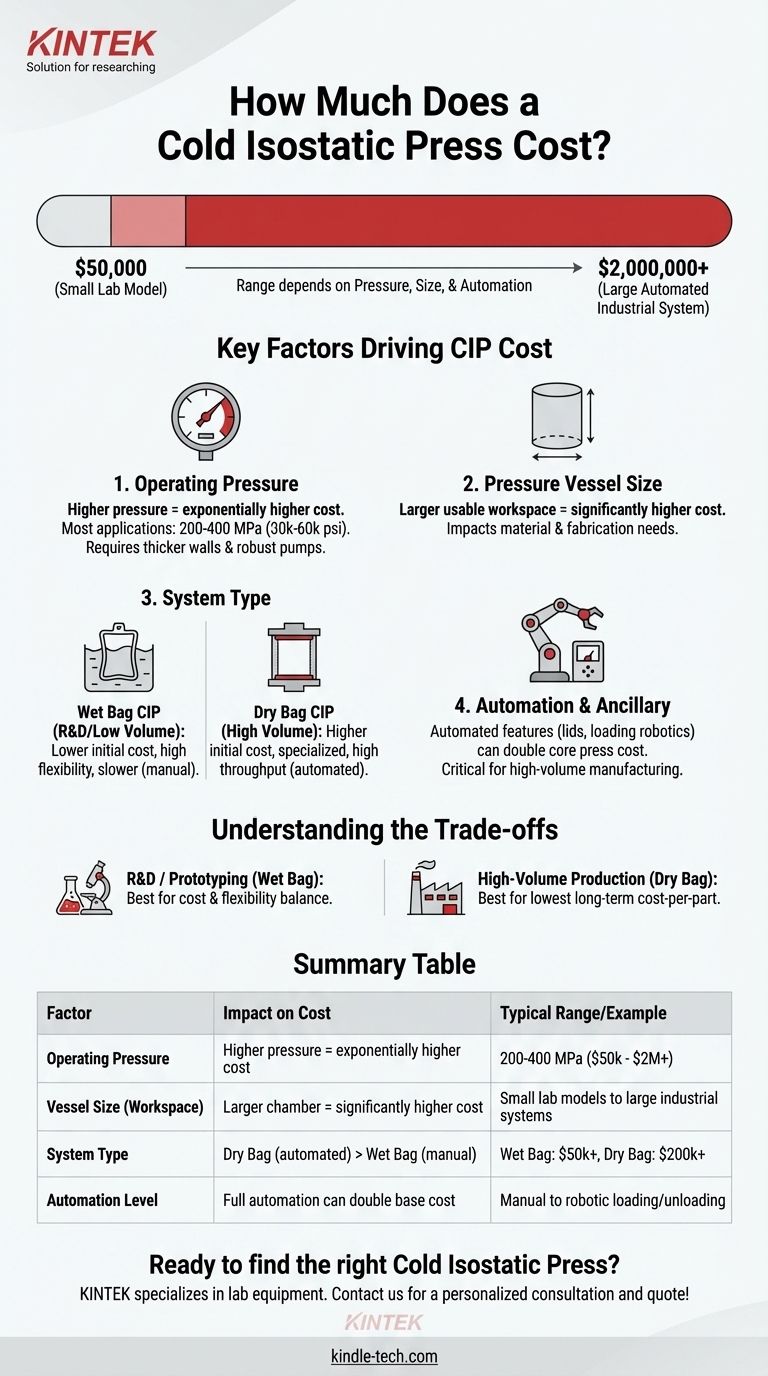

The cost of a cold isostatic press (CIP) ranges from approximately $50,000 for a small laboratory model to over $2,000,000 for a large, automated industrial system. This wide variation is not arbitrary; it is directly tied to the machine's pressure rating, chamber size, and level of automation. Understanding these key factors is essential for determining the true investment required for your specific application.

The final cost of a Cold Isostatic Press is not a fixed number but a direct function of your specific processing requirements. The primary cost drivers are the maximum operating pressure, the internal dimensions of the pressure vessel, and the degree of automation needed for your production volume.

Key Factors Driving CIP Cost

To budget effectively, you must move beyond a single price tag and analyze the components that define the machine's capability and, therefore, its cost.

Factor 1: Operating Pressure

The maximum pressure a CIP can generate is a fundamental cost driver. As pressure requirements increase, the engineering complexity and material strength of the pressure vessel must increase exponentially.

Most commercial applications fall between 200 to 400 MPa (30,000 to 60,000 psi). Systems designed for the higher end of this range require thicker vessel walls and more robust pump systems, significantly increasing their price.

Factor 2: Pressure Vessel Size

The usable workspace inside the pressure chamber directly impacts cost. A larger vessel requires more advanced materials and fabrication techniques to safely contain the immense pressures involved.

Consider the dimensions and quantity of the parts you need to press in a single cycle. A press for small ceramic components will be far less expensive than one designed for large near-net shape industrial parts.

Factor 3: System Type (Wet Bag vs. Dry Bag)

The method of applying pressure creates a major branching point in cost and application.

-

Wet Bag CIP: In this process, the flexible mold is sealed and submerged directly into the pressurizing fluid. These systems are highly versatile for R&D and low-volume production but are slower due to manual loading and unloading. They represent the lower end of the cost spectrum.

-

Dry Bag CIP: Here, the pressure chamber incorporates a permanent elastomeric membrane. The powder is placed inside this membrane, and the fluid pressurizes it from the outside. These systems are designed for high-throughput, automated production of specific part shapes and are significantly more expensive upfront.

Factor 4: Automation and Ancillary Systems

A basic, manually operated press is the most affordable option. However, production environments often require automation to achieve desired cycle times and reduce labor costs.

Features like automated vessel lids, part loading/unloading robotics, and integrated control systems can easily double the cost of the core press but are critical for high-volume manufacturing.

Understanding the Trade-offs

Choosing a CIP involves balancing initial investment against long-term operational efficiency. An inexpensive machine may not be the most cost-effective solution for your goal.

Initial Cost vs. Throughput

A low-cost, manual wet bag press is ideal for lab work but becomes a bottleneck in a production setting. An expensive, automated dry bag press has a high capital cost but can yield a much lower cost-per-part at high volumes due to speed and reduced labor.

Flexibility vs. Specialization

Wet bag systems offer maximum flexibility. You can press parts of varying sizes and shapes simply by creating new, inexpensive molds. This is perfect for prototyping or a high-mix, low-volume product line.

Dry bag systems are specialized. They are built for speed and efficiency in producing one specific part or a small family of similar parts. They offer very little flexibility for other geometries.

Operating Costs to Consider

The initial purchase price is only part of the total cost of ownership. You must also budget for:

- Tooling: The elastomeric molds or bags are consumables and need periodic replacement.

- Fluid & Maintenance: The pressurizing fluid (typically water with inhibitors) requires management and filtering. Seals and pumps also require routine maintenance.

- Facility Requirements: These are heavy machines that require significant floor space, reinforced foundations, and substantial electrical power.

Making the Right Choice for Your Goal

Select a machine based on a clear understanding of your primary objective, as this will align your budget with the right capabilities.

- If your primary focus is R&D, material development, or prototyping: A small-to-medium-sized wet bag press offers the best balance of cost and flexibility.

- If your primary focus is low-to-medium volume production of diverse parts: A larger wet bag press, possibly with semi-automated features like a powered lid, is your most logical choice.

- If your primary focus is high-volume, repeatable production of a single part: The higher initial investment in a fully automated dry bag system will deliver the lowest long-term cost per part.

Ultimately, defining your application with precision is the first and most critical step in determining the true cost of a cold isostatic press.

Summary Table:

| Factor | Impact on Cost | Typical Range/Example |

|---|---|---|

| Operating Pressure | Higher pressure = exponentially higher cost | 200-400 MPa ($50k - $2M+) |

| Vessel Size (Workspace) | Larger chamber = significantly higher cost | Small lab models to large industrial systems |

| System Type | Dry Bag (automated) is more expensive than Wet Bag (manual) | Wet Bag: $50k+, Dry Bag: $200k+ |

| Automation Level | Full automation can double the base machine cost | Manual operation to robotic loading/unloading |

Ready to find the right Cold Isostatic Press for your budget and application?

KINTEK specializes in lab equipment and consumables, serving laboratory needs. Our experts can help you navigate the trade-offs between initial cost, throughput, and flexibility to identify the perfect CIP solution for your R&D or production goals.

Contact us today for a personalized consultation and quote!

Visual Guide

Related Products

- Electric Lab Cold Isostatic Press CIP Machine for Cold Isostatic Pressing

- Manual Cold Isostatic Pressing Machine CIP Pellet Press

- Automatic Lab Cold Isostatic Press CIP Machine Cold Isostatic Pressing

- Manual High Temperature Heated Hydraulic Press Machine with Heated Plates for Lab

- Automatic High Temperature Heated Hydraulic Press Machine with Heated Plates for Lab

People Also Ask

- Why is a cold isostatic press (CIP) required after uniaxial pressing? Maximize LLZO Density & Performance

- What is the purpose of using a sealed laminated bag in CIP for battery components? Ensure Purity and High Density.

- How is isostatic pressing distinguished from conventional pressing? Unlock Superior Uniformity and Density

- What is the dry bag process? A Guide to High-Speed Isostatic Pressing

- Why is a Cold Isostatic Press (CIP) Required for NaSICON? Achieve Maximum Green Density and Ionic Conductivity

- What role does an industrial-grade high-pressure manual screw pump play in an HHIP system? Achieve Precise Densification

- How does a laboratory isostatic press contribute to the fabrication of LAGP solid-state electrolyte pellets?

- What is the difference between HIP and CIP? A Guide to Shaping vs. Densification