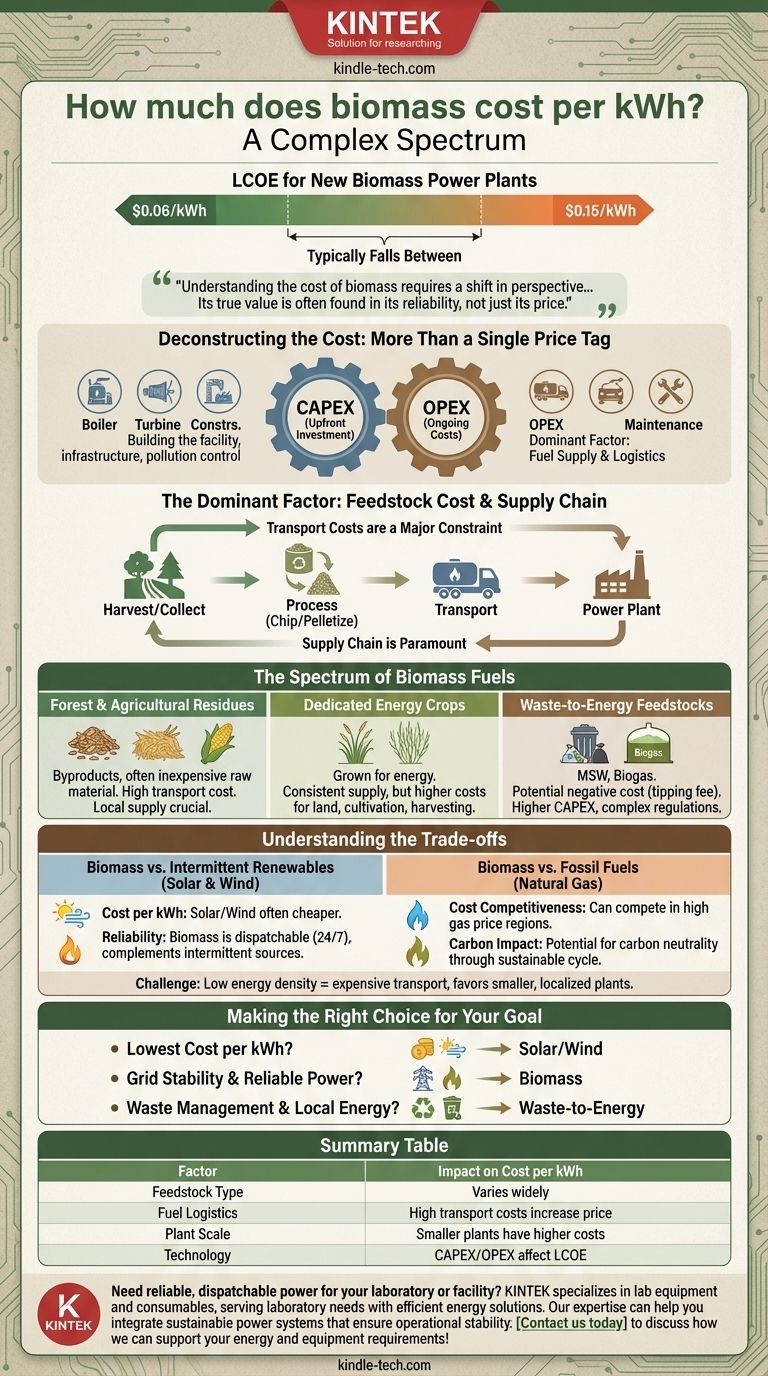

The cost of biomass per kilowatt-hour is not a single number, but a wide spectrum influenced by fuel, technology, and scale. The Levelized Cost of Energy (LCOE) for new biomass power plants typically falls between $0.06 and $0.15 per kWh. This places it in a complex position, often more expensive than new utility-scale solar or wind but potentially competitive with fossil fuels, especially when its unique benefits are considered.

Understanding the cost of biomass requires a shift in perspective. The final price per kWh is less about the power plant itself and more about the specific type, source, and logistical chain of the organic fuel it consumes. Its true value is often found in its reliability, not just its price.

Deconstructing the Cost: More Than a Single Price Tag

To understand the cost of biomass energy, we must look at the lifetime expenses of a power plant relative to its lifetime energy production. This is known as the Levelized Cost of Energy (LCOE), the standard metric for comparing different generation sources.

The Core Drivers: CAPEX and OPEX

The LCOE for biomass is primarily driven by two components: Capital Expenditures (CAPEX) and Operational Expenditures (OPEX).

CAPEX represents the upfront investment to build the facility. This includes the boiler, steam turbine, generator, pollution control systems, and crucial fuel handling and storage infrastructure.

OPEX represents the ongoing costs to run the plant. For biomass, the single most significant operating cost is nearly always the fuel itself.

The Dominant Factor: Feedstock Cost

Unlike solar or wind, a biomass plant must be continuously fed. The cost and type of this "feedstock" are the most critical variables determining the final price of electricity.

The supply chain is paramount. This includes the cost to harvest, collect, process (e.g., chip or pelletize), and transport the biomass to the power plant.

The Spectrum of Biomass Fuels

The term "biomass" covers a wide range of organic materials, each with a dramatically different cost profile.

Forest and Agricultural Residues

These materials, such as wood chips from forestry operations, corn stover, or straw, are often byproducts of other industries. This can make the raw material itself inexpensive, but transportation costs are a major constraint. A plant's viability often depends on a cheap, high-volume supply within a small radius.

Dedicated Energy Crops

These are plants like switchgrass or fast-growing willow that are grown specifically for energy production. While they provide a consistent and predictable fuel source, they introduce costs for land use, cultivation, and harvesting, making them a more expensive option.

Waste-to-Energy Feedstocks

This category includes Municipal Solid Waste (MSW) and biogas from anaerobic digesters (processing manure or food waste). These can have a negative feedstock cost, as the plant operator may be paid a "tipping fee" to accept the waste. However, these plants often have higher capital costs and more complex regulatory requirements.

Understanding the Trade-offs

No energy source exists in a vacuum. The economic case for biomass becomes clearer when compared to other options.

Biomass vs. Intermittent Renewables (Solar & Wind)

On a pure cost-per-kWh basis for new construction, utility-scale solar and wind are almost always cheaper than biomass.

However, solar and wind are intermittent—they only produce power when the sun is shining or the wind is blowing. Biomass is dispatchable, meaning it can be turned on and off on demand or run 24/7 to provide stable, baseload power. This reliability is a critical service for maintaining a stable grid.

Biomass vs. Fossil Fuels (Natural Gas)

Biomass can be cost-competitive with natural gas plants, particularly in regions with high gas prices or policies that price carbon emissions.

The primary advantage of biomass here is its potential for being carbon neutral. While burning biomass releases CO2, the cycle of growing new organic matter can reabsorb an equivalent amount of CO2 from the atmosphere, assuming the feedstock is managed sustainably.

The Challenge of Scale and Logistics

The "energy density" of biomass is low compared to fossil fuels. This means transporting it is expensive and inefficient. As a result, biomass plants are often smaller and more localized than coal or gas plants, which prevents them from achieving the same economies of scale.

Making the Right Choice for Your Goal

The decision to use or invest in biomass energy depends entirely on the strategic objective.

- If your primary focus is the absolute lowest cost per kWh: Utility-scale solar and wind are the leading choices for new electricity generation.

- If your primary focus is grid stability and reliable, renewable power: Biomass is a powerful contender, providing firm, dispatchable energy that perfectly complements intermittent renewables.

- If your primary focus is waste management and local energy production: Converting agricultural, forest, or municipal waste into energy can be a highly effective solution that solves multiple problems at once.

Ultimately, evaluating biomass requires looking beyond a single price tag to understand its unique role in a balanced and reliable energy system.

Summary Table:

| Factor | Impact on Cost per kWh |

|---|---|

| Feedstock Type | Varies widely (e.g., low-cost residues vs. expensive energy crops) |

| Fuel Logistics | High transport costs can significantly increase final price |

| Plant Scale | Smaller plants have higher costs due to lower economies of scale |

| Technology | Capital and operational expenditures (CAPEX/OPEX) affect LCOE |

Need reliable, dispatchable power for your laboratory or facility? KINTEK specializes in lab equipment and consumables, serving laboratory needs with efficient energy solutions. Our expertise can help you integrate sustainable power systems that ensure operational stability. Contact us today to discuss how we can support your energy and equipment requirements!

Visual Guide

Related Products

- Multifunctional Electrolytic Electrochemical Cell Water Bath Single Layer Double Layer

- Single Punch Manual Tablet Press Machine TDP Tablet Punching Machine

- Portable High Pressure Laboratory Autoclave Steam Sterilizer for Lab Use

- Custom PTFE Teflon Parts Manufacturer for PTFE Containers

- Automatic Heated Hydraulic Press Machine with Heated Plates for Laboratory Hot Press 25T 30T 50T

People Also Ask

- How should a double-layer water-bath electrolytic cell be operated? A Step-by-Step Guide for Reliable Results

- What are the post-use procedures for a five-port water bath electrolytic cell? Ensure Safety & Longevity

- What precautions should be taken regarding temperature control with a five-port water bath electrolytic cell? Ensure Safe and Accurate Electrochemical Experiments

- What are the key features of the five-port water bath electrolytic cell? Precision Control for Electrochemical Experiments

- What does the routine maintenance of a double-layer water-bath electrolytic cell involve? A Guide to Ensuring Precision and Longevity