Proper post-use procedure for a five-port water bath electrolytic cell follows a strict sequence: power down completely before disconnecting the circuit, safely manage the used electrolyte, thoroughly clean the cell and electrodes, and finally, dry and store all components correctly. This methodical approach is essential for user safety, equipment longevity, and the integrity of future experiments.

The core principle behind post-use care is not just cleaning, but a systematic process of neutralization. By safely de-energizing the system, removing reactive agents, and meticulously cleaning all components, you prevent corrosion, ensure safety, and eliminate cross-contamination.

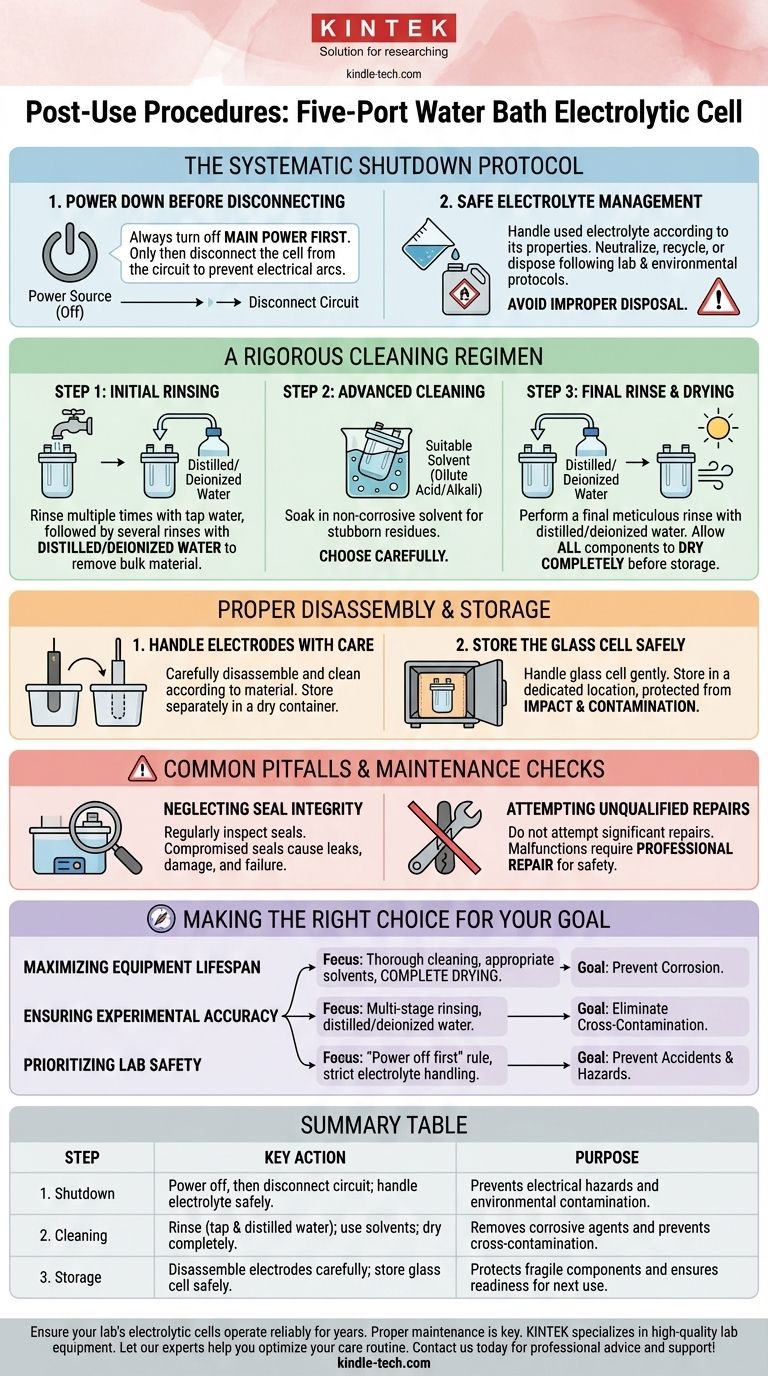

The Systematic Shutdown Protocol

The first steps after your experiment concludes are centered on safely de-energizing the system and managing the chemical components. The order of operations is critical to prevent accidents.

Step 1: Power Down Before Disconnecting

Always turn off the main power source first.

Only after the power is off should you disconnect the electrolytic cell from the electrical circuit. This specific order prevents the risk of electrical arcs or other safety incidents that can occur when disconnecting a live circuit.

Step 2: Safe Electrolyte Management

The used electrolyte must be handled according to its chemical properties.

This may involve neutralization, recycling, or disposal following proper laboratory and environmental protocols. Improper disposal can cause environmental pollution and damage to plumbing.

A Rigorous Cleaning Regimen

Thorough cleaning is essential to remove residual electrolyte and reaction byproducts, which can corrode the equipment and contaminate subsequent experiments.

Step 1: Initial Rinsing

Immediately after safely removing the electrolyte, rinse the glass cell multiple times with tap water, followed by several rinses with distilled or deionized water.

This initial step removes the bulk of the residual material and prepares the cell for deeper cleaning.

Step 2: Advanced Cleaning for Stubborn Residues

For any remaining residues or stubborn stains, a more targeted approach is necessary.

Soak the cell in a suitable, non-corrosive solvent. This may be a dilute acid or alkali, but the choice must be made carefully to avoid damaging the cell material.

Step 3: Final Rinse and Thorough Drying

After any advanced cleaning, perform a final, meticulous rinse with distilled or deionized water to ensure no cleaning agents remain.

Allow the cell and all its components to dry completely before storage. Moisture can promote corrosion and microbial growth.

Proper Disassembly and Storage

Correct storage protects your investment and ensures the equipment is ready for its next use.

Step 1: Handle Electrodes with Care

Carefully disassemble the electrodes from the cell apparatus.

Clean them according to their specific material requirements and store them properly. This often means storing them separately in a designated, dry container.

Step 2: Store the Glass Cell Safely

The electrolytic cell is typically made of glass, a fragile material. Always handle it gently to prevent breakage.

Store the clean, dry cell in a dedicated location where it is protected from impact and contamination.

Common Pitfalls and Maintenance Checks

Beyond the immediate post-use procedure, a proactive mindset toward maintenance is crucial for reliable operation.

Neglecting Seal Integrity

Regularly inspect the seals on both the water bath circulation system and the electrolytic cell ports.

Compromised seals can lead to water or gas leaks, which can cause equipment damage or outright experimental failure.

Attempting Unqualified Repairs

If you encounter significant issues, do not attempt to fix them yourself.

Problems like a malfunctioning water bath, damaged connection points, severe electrode damage, or electrical faults require professional repair to ensure safety and proper function.

Making the Right Choice for Your Goal

Your primary objective will slightly adjust the focus of your post-use procedure.

- If your primary focus is maximizing equipment lifespan: Emphasize thorough cleaning with appropriate solvents and ensure complete drying before storage to prevent any form of corrosion.

- If your primary focus is ensuring experimental accuracy: Concentrate on the multi-stage rinsing process with distilled or deionized water to eliminate any chance of chemical cross-contamination.

- If your primary focus is prioritizing lab safety: Adhere strictly to the "power off before disconnecting" rule and follow all protocols for safe handling and disposal of the electrolyte.

Ultimately, a consistent and meticulous post-use procedure transforms your equipment from a simple tool into a reliable and long-lasting scientific instrument.

Summary Table:

| Step | Key Action | Purpose |

|---|---|---|

| 1. Shutdown | Power off, then disconnect circuit; handle electrolyte safely. | Prevents electrical hazards and environmental contamination. |

| 2. Cleaning | Rinse (tap & distilled water); use solvents for residues; dry completely. | Removes corrosive agents and prevents cross-contamination. |

| 3. Storage | Disassemble electrodes carefully; store glass cell in a safe, dry place. | Protects fragile components and ensures readiness for next use. |

Ensure your lab's electrolytic cells operate reliably for years. Proper maintenance is key to safety and accurate results. KINTEK specializes in high-quality lab equipment and consumables, serving all your laboratory needs.

Let our experts help you optimize your equipment care routine. Contact us today for professional advice and support!

Visual Guide

Related Products

- Multifunctional Electrolytic Electrochemical Cell Water Bath Single Layer Double Layer

- Double-Layer Water Bath Electrolytic Electrochemical Cell

- H-Type Double-Layer Optical Electrolytic Electrochemical Cell with Water Bath

- Optical Water Bath Electrolytic Electrochemical Cell

- Quartz Electrolytic Electrochemical Cell for Electrochemical Experiments

People Also Ask

- What does the routine maintenance of a double-layer water-bath electrolytic cell involve? A Guide to Ensuring Precision and Longevity

- What are the pre-use procedures for a five-port water bath electrolytic cell? A 4-Step Guide for Reliable Results

- What precautions should be taken regarding temperature control with a five-port water bath electrolytic cell? Ensure Safe and Accurate Electrochemical Experiments

- What are the procedures for after using a double-layer water-bath electrolytic cell? Ensure Equipment Longevity and Data Accuracy

- How does the design of an electrolytic cell influence evaluation of electrochemical catalytic performance? Key Factors