Routine maintenance of a double-layer water-bath electrolytic cell is a systematic process focused on preserving its physical integrity and thermal performance. This involves the regular inspection of all components—including the glass body, seals, and electrodes—along with meticulous cleaning of the cell's surfaces to remove contaminants and residual electrolyte. Prompt replacement of any damaged parts is critical to ensure continued operational accuracy.

The primary advantage of a double-layer cell is precise temperature control. Therefore, effective maintenance goes beyond simple cleaning; it is about preserving the physical and thermal integrity required for accurate, stable, and repeatable electrochemical experiments.

The Purpose of Double-Layer Design

To understand maintenance, you must first understand the cell's design. An electrolytic cell drives non-spontaneous reactions using an external power source connected to two electrodes (an anode and a cathode) submerged in an electrolyte.

The Inner Electrolytic Chamber

This is the core reaction vessel. It contains the electrolyte (a solution with ions) and the electrodes. The integrity of this chamber is paramount for containing the reaction and ensuring the electrochemical process proceeds as intended.

The Outer Water Jacket

This second layer forms a bath around the inner chamber. Its sole purpose is to provide precise temperature control. By circulating water at a specific temperature, it ensures the reaction inside the cell remains stable, mitigating heat generated during electrolysis or fluctuations from the environment.

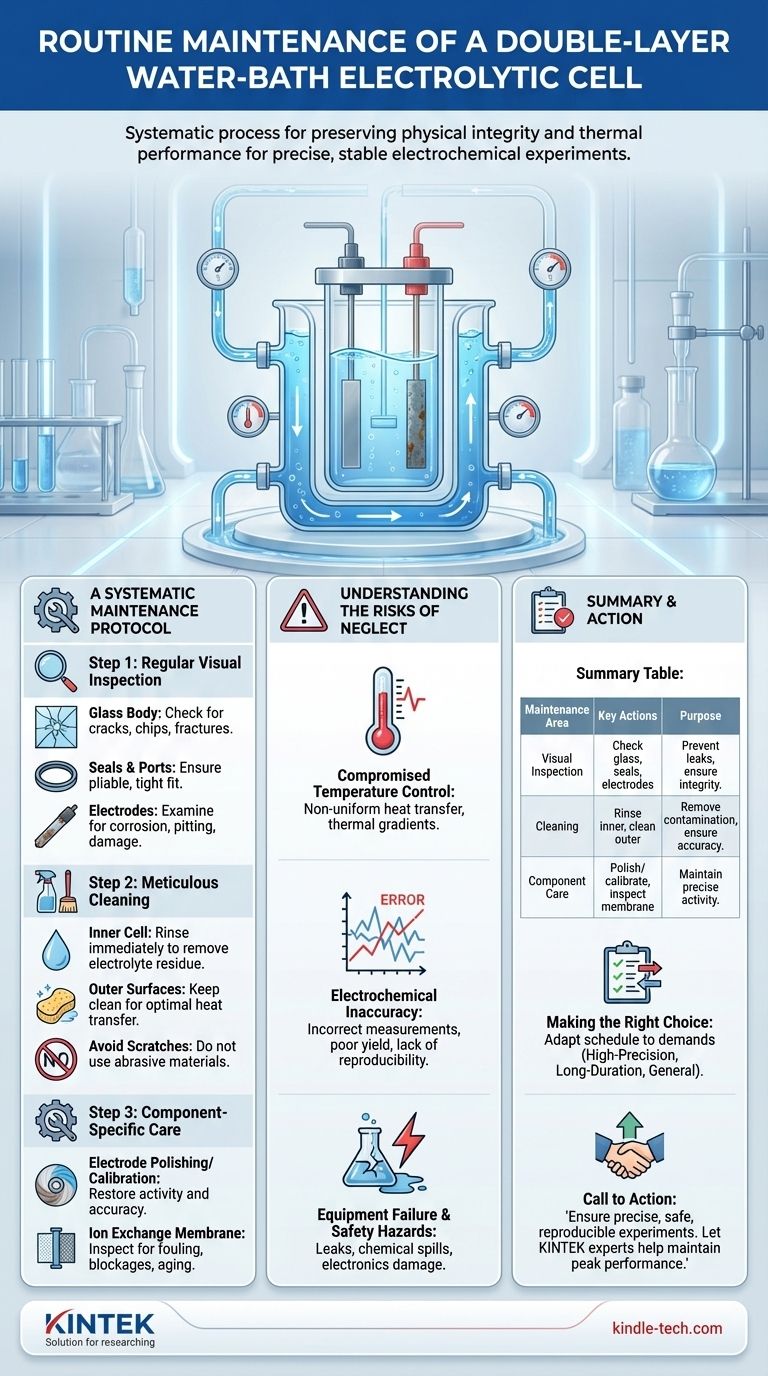

A Systematic Maintenance Protocol

A consistent maintenance routine prevents experimental failure and extends the life of the cell. This protocol should be divided into distinct areas of focus.

Step 1: Regular Visual Inspection

Before and after each use, conduct a thorough visual check.

- Glass Body: Inspect both the inner chamber and the outer water jacket for any cracks, chips, or fractures. Even a minor crack can compromise thermal regulation or lead to a catastrophic leak.

- Seals and Ports: Check that all seals, stoppers, and connection ports are pliable and form a tight fit. Hardened or cracked seals can cause leaks of either electrolyte or water from the jacket.

- Electrodes: Examine the electrodes for signs of corrosion, pitting, or physical damage. A compromised electrode surface will alter the reaction kinetics and invalidate your results.

Step 2: Meticulous Cleaning

Residue and contamination are sources of experimental error.

- Inner Cell: After use, immediately rinse the inner cell with an appropriate solvent to remove all residual electrolyte. Use a soft brush or cloth to gently clean the surfaces.

- Outer Surfaces: Keep the exterior of the cell and the water jacket clean to ensure optimal and uniform heat transfer from the water bath to the inner chamber.

- Avoid Scratches: Never use abrasive materials that could scratch the glass, as this creates stress points that may lead to future fractures.

Step 3: Component-Specific Care

Certain components require periodic, more intensive maintenance based on usage.

- Electrode Polishing: Depending on the electrode material and the reaction, the electrode surfaces may need to be polished or cleaned to remove passivation layers and restore their activity.

- Electrode Calibration: For quantitative work, electrodes must be periodically calibrated to ensure their response is accurate and reproducible.

- Ion Exchange Membrane: If your cell uses a membrane to separate the anode and cathode compartments, inspect it for fouling, blockages, or aging. Replace it according to the manufacturer's guidelines or when performance degrades.

Understanding the Risks of Neglect

Skipping maintenance introduces significant risks that compromise your research and equipment.

Compromised Temperature Control

A dirty or stained outer jacket surface hinders uniform heat transfer. This can create thermal gradients or prevent the cell from maintaining the target temperature, leading to inconsistent reaction rates and unreliable data.

Electrochemical Inaccuracy

Corroded electrodes or a fouled ion exchange membrane directly impact the electrochemical process. This leads to incorrect measurements, poor product yield in electrosynthesis, and a general lack of reproducibility between experiments.

Equipment Failure and Safety Hazards

An unchecked crack in the glass or a failed seal can lead to leaks. This not only ruins an experiment but can also damage surrounding equipment and create a safety hazard from spilled chemicals or water interacting with electronics.

Making the Right Choice for Your Goal

Your maintenance schedule should adapt to your experimental demands.

- If your primary focus is high-precision quantitative analysis: You must prioritize rigorous electrode calibration and meticulous cleaning of the inner cell after every single use to ensure data integrity.

- If your primary focus is long-duration electrosynthesis: Your maintenance should emphasize regular inspection of seals and the ion exchange membrane to prevent leaks and performance degradation over time.

- If your primary focus is general teaching or qualitative work: A balanced schedule of weekly visual inspections and thorough post-experiment cleaning is sufficient to maintain cell integrity and prolong its operational life.

Ultimately, consistent and thoughtful maintenance is the foundation for reliable and reproducible electrochemical research.

Summary Table:

| Maintenance Area | Key Actions | Purpose |

|---|---|---|

| Visual Inspection | Check glass for cracks, inspect seals, examine electrodes. | Prevent leaks and ensure physical integrity. |

| Cleaning | Rinse inner cell, clean outer surfaces, avoid abrasives. | Remove contamination for accurate thermal and electrochemical performance. |

| Component Care | Polish/calibrate electrodes, inspect/replace membrane. | Maintain precise electrochemical activity and separation. |

Ensure your electrochemical experiments are precise, safe, and reproducible. Proper maintenance of your double-layer water-bath electrolytic cell is critical for reliable data and long equipment life. KINTEK specializes in high-quality lab equipment and consumables, serving the precise needs of research and industrial laboratories. Let our experts help you maintain peak performance. Contact our team today to discuss your laboratory requirements and discover how our solutions can support your success.

Visual Guide

Related Products

- Double Layer Five-Port Water Bath Electrolytic Electrochemical Cell

- Double-Layer Water Bath Electrolytic Electrochemical Cell

- H-Type Double-Layer Optical Electrolytic Electrochemical Cell with Water Bath

- Multifunctional Electrolytic Electrochemical Cell Water Bath Single Layer Double Layer

- H Type Electrolytic Cell Triple Electrochemical Cell

People Also Ask

- How can the electrochemical reaction be controlled when using this electrolytic cell? Master Voltage, Current & Electrolyte

- What are the procedures for after using a double-layer water-bath electrolytic cell? Ensure Equipment Longevity and Data Accuracy

- What are the key features of the five-port water bath electrolytic cell? Precision Control for Electrochemical Experiments

- What are the standard aperture specifications of the electrolytic cell? Key Sizes for Your Electrochemical Setup

- What are the standard aperture sizes on the lid of the multifunctional electrolytic cell? Key Ports for Your Electrochemical Setup