The short answer is: the cost to PVD coat a single item can range from as little as a few dollars to several hundred dollars. The price is not based on a simple per-piece fee but is dictated by a wide range of factors, making a "standard" price impossible to quote without a detailed review of your project.

The true cost of PVD coating is a function of process, not just material. The majority of the expense is driven by the labor for part preparation and the operational time of the vacuum chamber, not the coating itself.

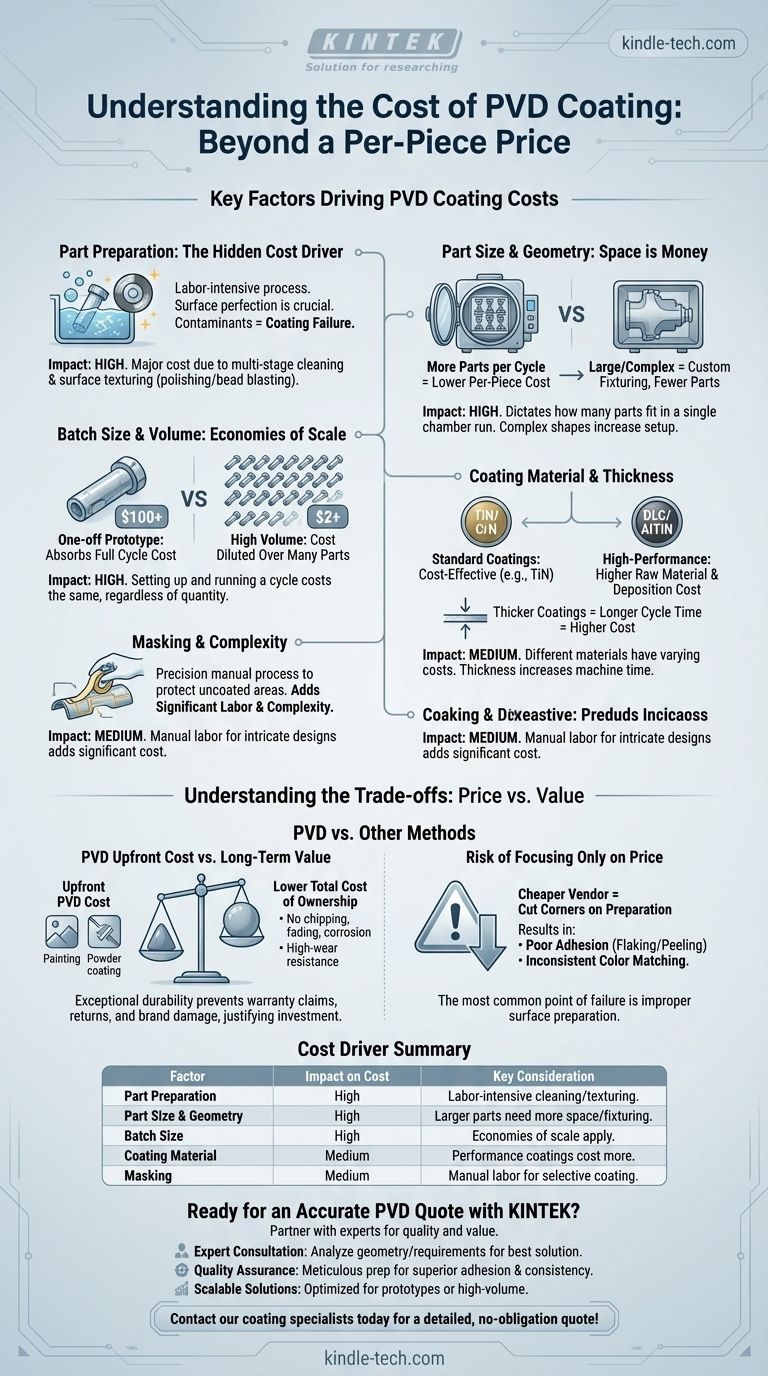

The Key Factors Driving PVD Coating Costs

To accurately budget for Physical Vapor Deposition (PVD), you must understand the individual components that contribute to the final price. The coating material is often one of the smallest factors.

Part Preparation: The Hidden Cost

Before a part can be coated, its surface must be perfect. This preparation phase is labor-intensive and often the most significant cost driver.

Any contaminants like oils, dirt, or even fingerprints will cause the coating to fail. This requires multi-stage ultrasonic cleaning and drying. Furthermore, the final appearance of the PVD finish is determined by the underlying surface texture. A polished part will have a polished PVD finish; a matte part will have a matte finish. Achieving this desired texture through polishing or bead blasting adds considerable labor costs.

Part Size and Geometry

PVD is a line-of-sight process performed in a vacuum chamber. The cost of running a cycle is relatively fixed, so the primary goal is to fit as many parts as possible into a single run.

Larger parts take up more space, meaning fewer can be coated at once, increasing the per-piece cost. Complex geometries may require custom fixturing or racking to hold them, adding to the setup cost and potentially reducing the number of parts per batch.

Batch Size and Volume

This is a classic economy-of-scale principle. The cost to set up and run a PVD chamber is the same whether it contains one part or one thousand parts.

A one-off prototype might cost $100 because it occupies an entire machine cycle. However, coating 10,000 of the same small part might bring the per-piece cost down to $2. The single highest cost driver for small projects is that they absorb the full overhead of a production run.

Coating Material and Thickness

Different PVD materials have different costs. Standard coatings like Titanium Nitride (TiN) or Chromium Nitride (CrN) are very cost-effective.

Higher-performance coatings like Diamond-Like Carbon (DLC) or multi-layer functional coatings (e.g., AlTiN) are more expensive due to raw material cost and the more complex deposition process they require. Thicker coatings also require longer cycle times, which increases the cost by consuming more machine time and energy.

Masking and Complexity

If only specific areas of your part need to be coated, the uncoated areas must be masked. This is a precise, manual process.

An operator must carefully apply special tapes or custom-made metal shields to the part. This meticulous labor can add significant cost, especially for intricate designs.

Understanding the Trade-offs

Choosing a coating service based on the lowest price can introduce significant risks to your product's quality and long-term performance.

PVD vs. Other Coating Methods

PVD often has a higher upfront cost compared to processes like painting or powder coating. However, its exceptional hardness, wear resistance, and chemical inertness mean it often has a lower total cost of ownership.

A PVD finish will not chip, fade, or corrode like paint. For high-wear components or premium products, this durability prevents warranty claims, returns, and damage to your brand's reputation, justifying the initial investment.

The Risk of Focusing Only on Price

The most common point of failure in PVD is not the coating itself, but improper surface preparation. A cheaper vendor may cut corners on cleaning or surface texturing to lower their price.

This results in poor adhesion, causing the coating to flake or peel over time. Inconsistent color matching between batches is another common issue with low-cost providers, which can be disastrous for a consumer product line.

How to Get an Accurate PVD Coating Quote

To determine if PVD is the right choice, you must engage with a coating partner with a clear understanding of your goals.

- If you are prototyping or have a small batch: Be prepared for a higher per-piece cost and seek a provider who specializes in R&D or small-volume work.

- If you are planning for mass production: Discuss how to optimize your part's design for efficient racking and minimal masking to significantly reduce the per-piece cost.

- If durability is your absolute priority: Specify the performance you need, and let the expert recommend the right coating (like DLC or AlTiN), understanding it may cost more than a standard aesthetic finish.

- If aesthetics are the main goal: Your primary focus should be on the surface preparation (e.g., polishing vs. bead blasting), as this defines the final look more than the coating itself.

Ultimately, evaluating PVD coating requires you to look beyond the price per piece and consider the total value it adds to your product.

Summary Table:

| Factor | Impact on Cost | Key Consideration |

|---|---|---|

| Part Preparation | High | Labor-intensive cleaning and surface texturing (polishing, blasting) is a major cost driver. |

| Part Size & Geometry | High | Larger/complex parts require more space and custom fixturing, increasing per-piece cost. |

| Batch Size | High | Economies of scale apply; small batches absorb the full cost of a production run. |

| Coating Material | Medium | Standard coatings (TiN) are cost-effective; high-performance coatings (DLC) cost more. |

| Masking | Medium | Manually masking specific areas to avoid coating adds labor and complexity. |

Ready to Get an Accurate Quote for Your PVD Coating Project?

Understanding the factors that drive cost is the first step. Partnering with the right expert is the next. KINTEK specializes in precision PVD coating services for laboratories and manufacturers. We provide:

- Expert Consultation: We analyze your part's geometry, material, and performance requirements to recommend the most efficient and cost-effective coating solution.

- Quality Assurance: Our meticulous surface preparation and controlled deposition processes ensure superior adhesion, consistent color matching, and long-lasting durability for your products.

- Scalable Solutions: Whether you need a single prototype coating or high-volume production, we optimize our processes to deliver the best value.

Don't let an inaccurate quote risk your product's quality. Let KINTEK's expertise in lab equipment and consumables ensure your coating project is a success.

Contact our coating specialists today for a detailed, no-obligation quote!

Visual Guide

Related Products

- RF PECVD System Radio Frequency Plasma-Enhanced Chemical Vapor Deposition RF PECVD

- Chemical Vapor Deposition CVD Equipment System Chamber Slide PECVD Tube Furnace with Liquid Gasifier PECVD Machine

- Split Chamber CVD Tube Furnace with Vacuum Station Chemical Vapor Deposition System Equipment Machine

- VHP Sterilization Equipment Hydrogen Peroxide H2O2 Space Sterilizer

- Molybdenum Tungsten Tantalum Special Shape Evaporation Boat

People Also Ask

- What are the advantages of PECVD? Enable Low-Temperature, High-Quality Thin-Film Deposition

- What are the applications of PECVD? Essential for Semiconductors, MEMS, and Solar Cells

- How does RF power create plasma? Achieve Stable, High-Density Plasma for Your Applications

- What is an example of PECVD? RF-PECVD for High-Quality Thin Film Deposition

- How are PECVD and CVD different? A Guide to Choosing the Right Thin-Film Deposition Process