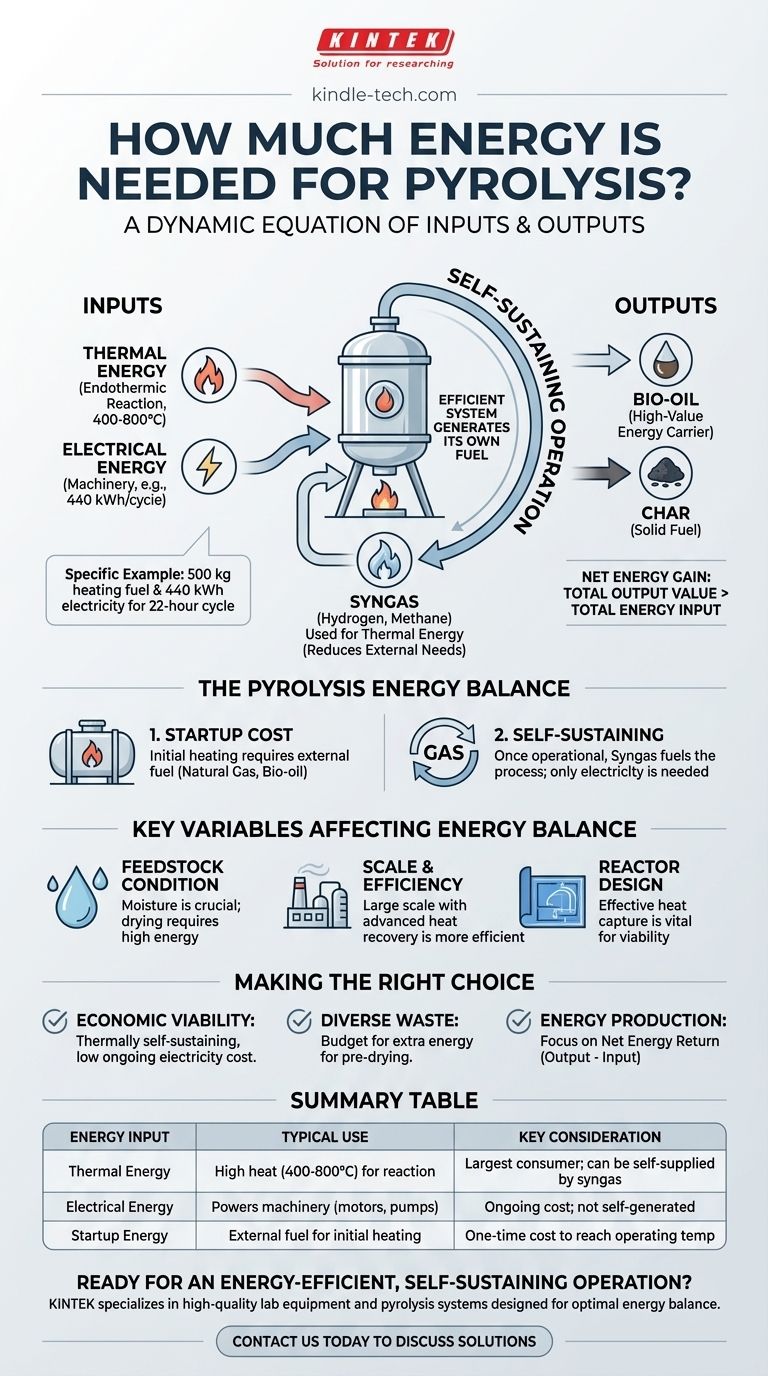

The energy required for pyrolysis is not a single number, but rather a dynamic equation of inputs and outputs. For a specific middle-scale plant, the input might be around 500 kg of heating fuel and 440 kWh of electricity for a 22-hour cycle. However, this only tells half the story, as an efficient pyrolysis system is designed to generate its own fuel from the waste it processes.

The core issue is not how much energy pyrolysis consumes, but whether the process is energy self-sustaining. While it requires significant initial heat to start, a well-designed system uses the energy-rich syngas it produces to fuel its own continued operation, dramatically reducing external energy needs.

The Two Types of Energy Input

Understanding the energy needs of pyrolysis requires separating them into two distinct categories: thermal energy to drive the reaction and electrical energy to run the machinery.

Thermal Energy: The Primary Requirement

Pyrolysis is an endothermic process. It requires a constant input of high heat (typically 400-800°C) in an oxygen-free environment to break down feedstock like plastic or biomass into smaller molecules.

This thermal energy is the largest energy consumer in the entire process. The exact amount depends heavily on the feedstock's nature and the reactor's efficiency.

Electrical Energy: Powering the System

In addition to heat, the system requires electricity to operate its components. This includes motors for shredders and conveyors, pumps for moving liquids, and the control systems that manage temperature and pressure.

A power draw of 20 kW, as cited for a middle-scale plant, translates to 440 kWh over a 22-hour cycle, a non-trivial operational cost.

The Pyrolysis Energy Balance: Input vs. Output

The crucial insight is that pyrolysis is both an energy consumer and an energy producer. The viability of any project hinges on this balance.

The Initial Startup Cost

To begin the process, the reactor must be heated to its target temperature using an external fuel source. This could be natural gas, electricity, or, more commonly, bio-oil saved from a previous batch.

Achieving Self-Sustaining Operation

Once the feedstock begins to break down, it produces three main products: solid char, liquid bio-oil, and a non-condensable gas known as syngas.

This syngas is rich in combustible compounds like hydrogen and methane. In an efficient plant, this gas is captured and piped back to the reactor's burner, providing the thermal energy needed to continue the process.

After the initial startup phase, the system can become thermally self-sustaining, using its own byproduct as its primary fuel. The external energy need then drops to only the electricity required to run the machinery.

The Net Energy Gain

The primary products, bio-oil and char, are themselves high-value energy carriers. The bio-oil can be refined into transportation fuels, and the char can be used as a solid fuel. Therefore, while the process requires energy to run, the total energy value of its outputs is typically far greater than the total energy input.

Understanding the Key Variables and Trade-offs

Not all pyrolysis systems are created equal. The energy balance is dramatically affected by three factors.

Feedstock Condition is Crucial

The moisture content of your feedstock is the single most important variable. Processing wet biomass requires a massive amount of extra energy to first boil off the water before pyrolysis can even begin. Dry feedstocks like plastics are far more energy-efficient.

Scale and System Efficiency

Small, lab-scale units are often very energy-inefficient due to poor insulation and heat loss. Large, industrial-scale plants are engineered with advanced heat recovery systems and superior insulation, making it much easier to achieve and maintain self-sustaining operation.

Technology and Reactor Design

The design of the pyrolysis reactor and its associated heat-capture systems plays a major role. A poorly designed system will fail to effectively capture and reuse the heat from the syngas, requiring continuous external fuel input and rendering the operation economically unviable.

Making the Right Choice for Your Goal

The "right" amount of energy depends entirely on your objective and the system you are evaluating.

- If your primary focus is economic viability: Your analysis must confirm the system is thermally self-sustaining after startup. The only significant ongoing energy cost should be electricity.

- If your primary focus is processing diverse waste: You must budget for the significant additional energy required for pre-drying wet or contaminated feedstock.

- If your primary focus is energy production: The key metric is the Net Energy Return—the total energy value of the produced bio-oil and char minus the electrical input needed to run the plant.

Ultimately, evaluating a pyrolysis system requires looking beyond the initial energy input and focusing on the complete energy balance of the entire process.

Summary Table:

| Energy Input | Typical Use/Requirement | Key Consideration |

|---|---|---|

| Thermal Energy | High heat (400-800°C) to drive the endothermic reaction. | Largest energy consumer; can be self-supplied by syngas. |

| Electrical Energy | Powers machinery (e.g., motors, pumps, controls). | Ongoing operational cost; not self-generated. |

| Startup Energy | External fuel (e.g., natural gas, bio-oil) for initial heating. | One-time cost per batch to reach operating temperature. |

Ready to achieve an energy-efficient, self-sustaining pyrolysis operation for your laboratory? KINTEK specializes in high-quality lab equipment and consumables, including pyrolysis systems designed for optimal energy balance and maximum yield. Our experts can help you select the right technology to meet your specific goals for waste processing or energy production.

Contact us today to discuss how KINTEK's solutions can enhance your lab's efficiency and sustainability!

Visual Guide

Related Products

- Rotary Tube Furnace Split Multi Heating Zone Rotating Tube Furnace

- Vacuum Sealed Continuous Working Rotary Tube Furnace Rotating Tube Furnace

- 1700℃ Laboratory High Temperature Tube Furnace with Alumina Tube

- 1400℃ Laboratory High Temperature Tube Furnace with Alumina Tube

- Vertical Laboratory Tube Furnace

People Also Ask

- How does pyrolysis start? Unlock the Molecular Trigger for Efficient Biomass Conversion

- What is the purpose of the rotary kiln? A Guide to Continuous High-Temperature Processing

- What are the parameters of a rotary kiln? Mastering Control for Optimal Process Results

- What are the catalysts for fast pyrolysis? Overcoming Biomass Conversion Challenges

- Can reactors be used for the pyrolysis of plastic waste? The Core Technology Explained

- What are the different types of rotary kiln incinerators? Find the Right Design for Your Waste Stream

- What is activated carbon method? A Deep Dive into Purification via Adsorption

- What is the temperature of carbon reactivation? Optimize Your Process Between 700°C and 900°C