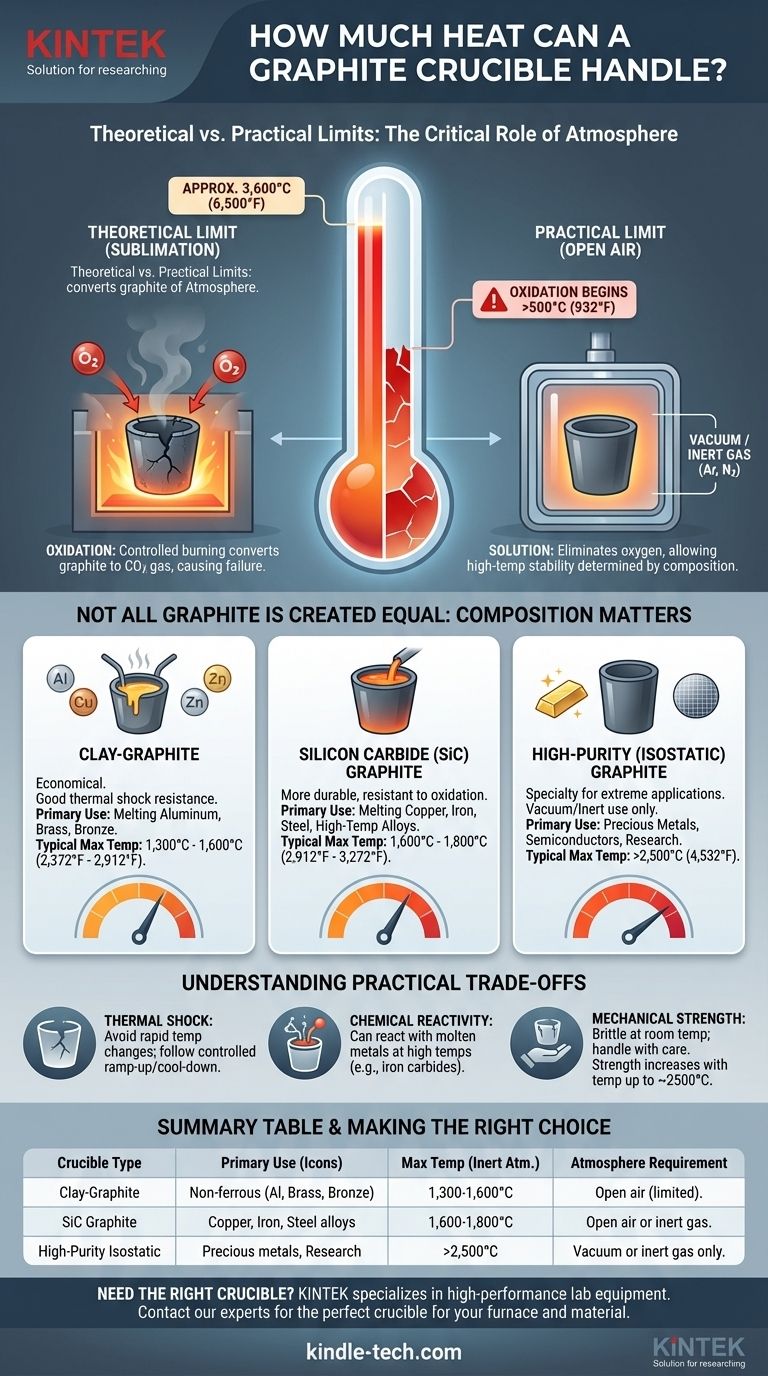

In theory, a graphite crucible can withstand temperatures up to its sublimation point of approximately 3,600°C (6,500°F). However, this number is misleading for most real-world applications. The practical, safe operating temperature of a graphite crucible is significantly lower and depends entirely on its specific material composition and, most critically, the atmosphere in which it is heated.

The true temperature limit of a graphite crucible is not a single number. In open air, oxidation begins to destroy the crucible above 500°C (932°F). To reach temperatures of 1,500°C to over 2,500°C, you must use the correct type of crucible within a vacuum or an inert gas atmosphere.

The Critical Factor: Atmosphere and Oxidation

The single greatest limitation for a graphite crucible is not its melting point but its reaction to oxygen. This is the primary reason for premature failure in many workshop and industrial settings.

The Problem with Oxygen

Graphite is a form of carbon. When heated in the presence of oxygen (i.e., in open air), it does not melt; it oxidizes. This is essentially a controlled burning process that converts the solid carbon of the crucible into carbon dioxide gas.

When Oxidation Begins

This process begins at temperatures as low as 500°C (932°F). As the temperature increases, the rate of oxidation accelerates dramatically. A crucible held at high temperatures in an open-air furnace will visibly shrink, become thin, and ultimately fail.

The Solution: Inert Environments

To utilize graphite's incredible high-temperature stability, you must remove oxygen from the equation. This is achieved by using the crucible inside a vacuum furnace or an environment flooded with an inert gas, such as argon or nitrogen. In this controlled atmosphere, oxidation is prevented, and the crucible's limit is instead determined by its material composition.

Not All Graphite Is Created Equal

Crucibles are rarely made of pure, raw graphite. They are engineered composites designed for specific tasks, and their composition directly dictates their performance and temperature limits.

Clay-Graphite Crucibles

These are a common and economical choice, made from a mixture of graphite, clay, and other binders. They offer good thermal shock resistance.

- Primary Use: Melting non-ferrous metals like aluminum, brass, and bronze.

- Typical Max Temperature: Around 1,300°C to 1,600°C (2,372°F to 2,912°F).

Silicon Carbide (SiC) Graphite Crucibles

These crucibles are infused with silicon carbide, making them far more durable, resistant to oxidation, and excellent at conducting heat. This is a very common choice for demanding applications.

- Primary Use: Melting copper, iron, steel, and other high-temperature alloys.

- Typical Max Temperature: Around 1,600°C to 1,800°C (2,912°F to 3,272°F).

High-Purity (Isostatic) Graphite

Machined from solid blocks of high-purity, isostatically-pressed graphite, these are specialty crucibles for the most extreme applications. They are only suitable for use in vacuum or inert atmospheres.

- Primary Use: Melting precious metals, silicon for semiconductors, and research applications.

- Typical Max Temperature: Can exceed 2,500°C (4,532°F), approaching the theoretical sublimation point under ideal conditions.

Understanding the Practical Trade-offs

Beyond temperature, several other factors can lead to crucible failure. Understanding these limitations is critical for safe and successful operation.

The Risk of Thermal Shock

Graphite, while stable at high temperatures, can crack if heated or cooled too quickly. This thermal shock is a leading cause of failure. Always follow a controlled, gradual ramp-up and cool-down procedure.

Chemical Reactivity and Contamination

At very high temperatures, graphite can react with certain molten metals. For example, it can dissolve into molten iron, increasing the melt's carbon content and forming iron carbides. This can both contaminate your final product and degrade the crucible itself.

Mechanical Strength

While graphite gets stronger with temperature up to a certain point (around 2500°C), it becomes more brittle at room temperature and can be fragile if mishandled. Always inspect a crucible for cracks before use.

Making the Right Choice for Your Melt

Your choice must align with the material you are melting and the furnace environment you are using.

- If your primary focus is melting non-ferrous metals (aluminum, brass, bronze) in an open-air furnace: A clay-graphite or silicon carbide crucible is your most reliable and cost-effective choice.

- If your primary focus is melting ferrous metals (iron, steel) or high-temperature copper alloys: A high-quality silicon carbide crucible is essential for its durability and superior high-temperature performance.

- If your primary focus is melting reactive metals, precious metals, or materials for research: You must use a high-purity graphite crucible within a vacuum or inert gas furnace to prevent both oxidation and contamination.

Ultimately, understanding the interplay between atmosphere and material composition is the key to maximizing the performance and lifespan of your crucible.

Summary Table:

| Crucible Type | Primary Use | Max Temperature (Inert Atmosphere) | Atmosphere Requirement |

|---|---|---|---|

| Clay-Graphite | Non-ferrous metals (Al, Brass, Bronze) | 1,300°C - 1,600°C | Open air (limited) |

| Silicon Carbide (SiC) Graphite | Copper, Iron, Steel alloys | 1,600°C - 1,800°C | Open air or inert gas |

| High-Purity Isostatic Graphite | Precious metals, Semiconductors, Research | >2,500°C (up to 3,600°C) | Vacuum or inert gas only |

Need the right crucible for your specific application? KINTEK specializes in high-performance lab equipment and consumables, including graphite crucibles engineered for maximum temperature resistance and longevity. Whether you're melting non-ferrous metals, high-temperature alloys, or conducting precision research, our experts can help you select the perfect crucible for your furnace environment and material requirements. Contact our technical team today for personalized guidance and to ensure your melting operations achieve optimal results with the right equipment.

Visual Guide

Related Products

- 1400℃ Laboratory High Temperature Tube Furnace with Alumina Tube

- Engineering Advanced Fine Alumina Al2O3 Ceramic Crucible for Laboratory Muffle Furnace

- Vertical High Temperature Graphite Vacuum Graphitization Furnace

- 1700℃ Laboratory High Temperature Tube Furnace with Alumina Tube

- Graphite Vacuum Continuous Graphitization Furnace

People Also Ask

- What are the typical heating zone configurations and maximum temperature capabilities of tube furnaces? Find the Right Setup for Your Lab

- How does a quartz tube vacuum furnace contribute to the crystallization process of Ag-doped Li-argyrodite electrolytes?

- How does a high-temperature tube furnace facilitate the phase transformation of alumina products? Master Thermal Control

- What precautions should be taken when using a tube furnace? Ensure Safe, Effective High-Temperature Processing

- What materials are used for the tubes in tube furnaces? A Guide to Selecting the Right Tube for Your Process