The short answer is there is no single, universal schedule for hydraulic maintenance. While manufacturers often recommend initial service intervals, such as changing filters after the first 50 hours and then every 500 to 1,000 hours, these are merely starting points. The true frequency depends entirely on the machine's operating conditions, environment, and the results of ongoing fluid analysis.

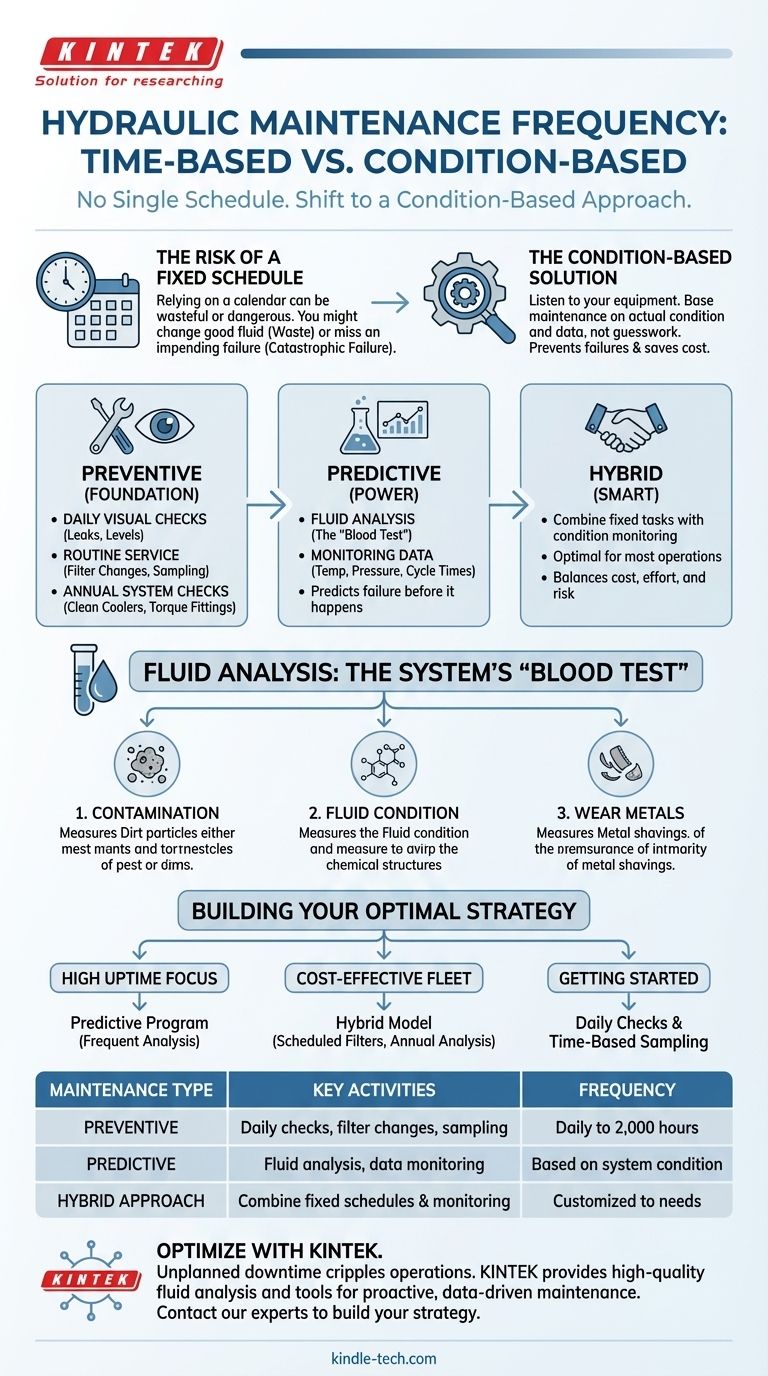

The most effective hydraulic maintenance strategy is not based on a fixed calendar, but on the actual condition of the system. Shifting from a time-based to a condition-based approach prevents both catastrophic failures and unnecessary, costly servicing.

From Calendar Guesses to Condition-Based Certainty

Relying solely on hours of operation is a blunt instrument for maintenance. A hydraulic system operating in a climate-controlled factory has vastly different needs than one on a mobile rig in a dusty, high-temperature environment. The goal is to move beyond guesswork and listen to what the equipment is telling you.

The Foundation: Preventive Maintenance Schedules

Preventive maintenance is your baseline. These are the scheduled, non-negotiable tasks that form the backbone of your reliability program.

Daily Visual Checks This is the simplest yet most effective form of maintenance. A trained operator should perform a quick walk-around at the start of every shift, checking for:

- Obvious leaks from hoses, fittings, or seals.

- Correct fluid levels in the reservoir.

- Signs of hose abrasion, cracking, or blistering.

- Any unusual noises or vibrations during operation.

Routine Service Intervals (500-2,000 Hours) This is where the manufacturer's recommendations come into play. These intervals are typically for replacing consumable items.

- Change Filters: Replace hydraulic filters according to the schedule or when the filter bypass indicator activates.

- Take a Fluid Sample: Draw a sample of the hydraulic fluid for analysis. This is the most critical step in determining future maintenance needs.

Annual or Semi-Annual System Checks Deeper inspections should be performed at least once a year.

- Clean Heat Exchangers: Ensure radiators and coolers are free of debris to maintain proper operating temperatures.

- Check Accumulators: Verify the nitrogen pre-charge in any accumulators to ensure they are functioning correctly.

- Torque Fittings: Check and torque critical fasteners and fittings, especially after initial machine run-in.

The Power of Predictive Maintenance

Predictive maintenance uses data to predict failure before it happens. For hydraulics, this revolves around one central practice: fluid analysis.

Fluid Analysis: The System's "Blood Test"

Sending a fluid sample to a lab provides a detailed report on the health of your hydraulic system. It is the single most valuable diagnostic tool you have.

The analysis looks for three key things:

- Contamination: Measures the presence of dirt, water, and metal particles. High particle counts indicate a dirty environment or an internal component beginning to fail.

- Fluid Condition: Checks the fluid's viscosity and chemical makeup (additive package). This tells you if the fluid itself has broken down due to heat or oxidation.

- Wear Metals: Identifies the specific types of metal particles in the fluid (e.g., copper, iron, aluminum), which can pinpoint exactly which component (a brass bushing, a steel pump gear) is wearing out.

Monitoring Operating Parameters

Beyond fluid analysis, keep an eye on performance data.

- Temperature: A system that is suddenly running hotter than its baseline indicates a problem, such as internal bypassing or an inefficient cooler.

- Pressure: A drop in system pressure or an inability to reach relief pressure can signal a worn pump or leaking valve.

- Cycle Times: If a hydraulic function becomes slower over time, it's a clear indicator of reduced efficiency somewhere in the system.

Understanding the Trade-offs

Choosing a maintenance strategy involves balancing cost, effort, and risk.

The Risk of a Fixed Schedule

Relying only on a calendar can be wasteful and dangerous. You might change fluid and filters that are still in perfect condition, wasting money.

Worse, you could miss an impending failure because the service interval hasn't arrived yet, leading to catastrophic damage and extensive downtime.

The Investment in a Condition-Based Program

A predictive program requires more upfront effort. You need to establish baseline data, train personnel to take clean fluid samples, and pay for lab analysis.

However, the return on investment is enormous. It extends the life of components, maximizes the useful life of your hydraulic fluid, and dramatically reduces unplanned downtime.

The Smart Hybrid Approach

For many operations, a hybrid model is the most practical solution.

- Follow a fixed schedule for low-cost, easy tasks like daily inspections and routine filter changes.

- Use condition monitoring (especially fluid analysis) to make the big, expensive decisions, such as when to change the hydraulic fluid or schedule a major component overhaul.

Building Your Optimal Maintenance Strategy

There is no one-size-fits-all answer, so your strategy should align with your operational goals and the criticality of the equipment.

- If your primary focus is maximum uptime for critical machinery: Implement a robust predictive maintenance program centered on frequent fluid analysis and performance monitoring.

- If your primary focus is cost-effective management of a large, diverse fleet: Use a hybrid model with scheduled filter changes and biannual or annual fluid analysis to guide major service decisions.

- If you are just getting started with a formal program: Begin with rigorous daily inspections and a time-based schedule for taking oil samples—the data you collect will quickly show you where to focus your efforts.

By shifting your focus from a rigid calendar to the actual condition of your equipment, you move from reactive repair to proactive reliability.

Summary Table:

| Maintenance Type | Key Activities | Frequency |

|---|---|---|

| Preventive | Daily visual checks, filter changes, fluid sampling | Daily to 2,000 hours |

| Predictive | Fluid analysis, temperature/pressure monitoring | Based on system condition |

| Hybrid Approach | Combine fixed schedules with condition monitoring | Customized to operational needs |

Optimize Your Hydraulic System Reliability with KINTEK

Unplanned downtime and costly repairs can cripple your operations. KINTEK specializes in providing high-quality hydraulic fluid analysis equipment and consumables that empower you to shift from reactive fixes to proactive, data-driven maintenance.

By partnering with us, you gain access to:

- Precision Sampling Kits: Ensure clean, representative fluid samples for accurate lab results.

- Advanced Monitoring Tools: Track system temperature, pressure, and contamination levels in real-time.

- Expert Support: Our team helps you interpret fluid analysis data to predict failures before they happen.

Take the guesswork out of hydraulic maintenance. Contact our lab experts today to build a customized condition-based strategy that maximizes uptime and extends the life of your critical machinery.

Visual Guide

Related Products

- Laboratory Manual Hydraulic Pellet Press for Lab Use

- Hydraulic Diaphragm Lab Filter Press for Laboratory Filtration

- Laboratory Test Sieves and Sieving Machines

- HFCVD Machine System Equipment for Drawing Die Nano-Diamond Coating

- Variable Speed Peristaltic Pump

People Also Ask

- What is the role of a laboratory hydraulic press in Rare Earth Element (REE) analysis? Unlock High-Precision XRF & LIBS

- What are the advantages of using a laboratory manual hydraulic pellet press for FTIR? Enhance Your Spectral Data

- What function does a laboratory hydraulic press serve in the preparation of LLZTO ceramic electrolyte pellets?

- Why is a hydraulic press used for vacuum carbothermic magnesium reduction pellets? Protect Systems & Enhance Gas Flow

- What is the use of a hydraulic pellet press? Transform Powders into Precise Samples for Analysis