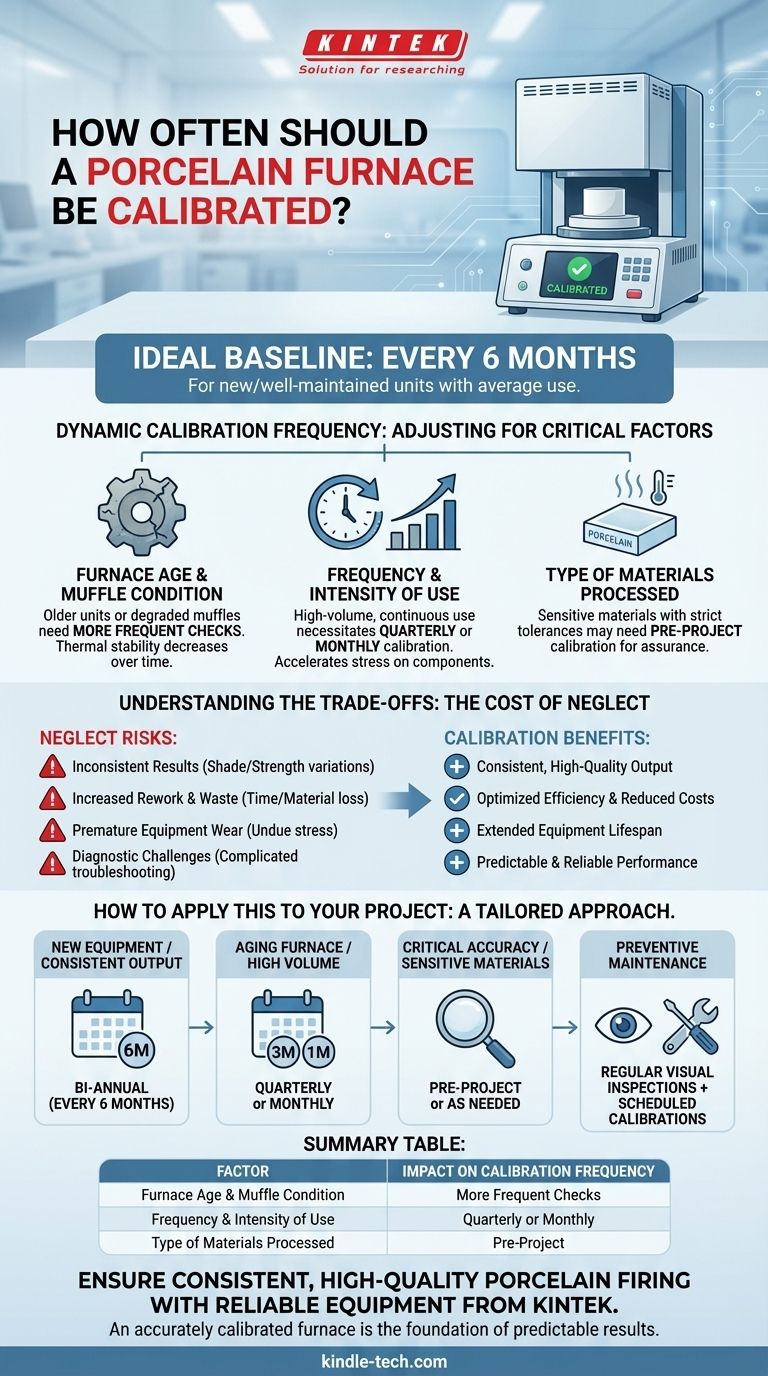

A porcelain furnace should ideally be calibrated every 6 months for a new or well-maintained unit with average use. However, this frequency is not static; it dynamically adjusts based on critical factors such as the furnace's age, the muffle's condition, and its operational intensity. Increased usage or an aging furnace necessitates more frequent checks to maintain precision.

Consistent and accurate firing is paramount in porcelain work, and calibration is the bedrock of achieving this reliability. The optimal calibration schedule is a balance between proactive maintenance and reactive adjustments, ensuring stable thermal performance and consistent product quality while minimizing operational downtime and costs.

The Foundation of Firing Accuracy

Accurate temperature control is non-negotiable for successful porcelain firing. Calibration ensures that the furnace's displayed temperature precisely matches the actual internal temperature. Deviations can lead to significant issues.

Why Calibration is Essential

Poor temperature control can result in under-fired or over-fired porcelain. This directly impacts the material's strength, aesthetics, and fit. Regular calibration safeguards the quality of your output.

Key Factors Influencing Calibration Frequency

The "every 6 months" guideline is a starting point. Several variables will dictate whether you need to calibrate more or less often. Understanding these factors allows for a tailored maintenance schedule.

Furnace Age and Muffle Condition

Older furnaces naturally experience more wear and tear, including changes to heating elements and insulation. The muffle, the internal chamber where firing occurs, can degrade over time, affecting heat distribution. As these components age, the furnace's thermal stability can decrease, requiring more frequent calibration.

Frequency and Intensity of Use

A furnace operating continuously or handling high volumes of work will accumulate operational hours much faster than one used intermittently. High-frequency usage subjects the heating elements and thermocouple to greater stress, accelerating the need for calibration.

Type of Materials Processed

Certain porcelain materials or firing cycles may have stricter temperature tolerances. If your work involves highly sensitive materials, more frequent calibration provides an additional layer of assurance.

Understanding the Trade-offs

Neglecting regular calibration can seem like a cost-saving measure in the short term, but it almost invariably leads to more significant expenses and compromises in the long run.

Risk of Inconsistent Results

Uncalibrated furnaces can produce inconsistent firing results, leading to variations in shade, translucency, and strength. This variability directly affects product quality and customer satisfaction.

Increased Rework and Material Waste

When firing results are unpredictable, the likelihood of needing to re-fire or entirely re-make pieces increases dramatically. This wastes valuable time, labor, and expensive porcelain materials.

Premature Equipment Wear

While not directly causing wear, operating a furnace outside its optimal thermal parameters due to calibration issues can put undue stress on components. This can potentially shorten the lifespan of elements or the muffle.

Diagnostic Challenges

If problems arise with your fired products, an uncalibrated furnace complicates troubleshooting. It becomes difficult to discern if the issue stems from material properties, technique, or the furnace itself.

How to Apply This to Your Project

Establishing a robust calibration protocol is an investment in quality and efficiency. Adjust your approach based on your specific operational context and priorities.

- If your primary focus is consistent, high-quality output with new equipment: Adhere to a bi-annual (every 6 months) calibration schedule.

- If your primary focus is optimizing an aging furnace or managing high production volumes: Implement a quarterly (every 3 months) or even monthly calibration schedule, especially if you notice subtle shifts in results.

- If your primary focus is troubleshooting or ensuring critical accuracy for sensitive materials: Consider calibration before significant projects or whenever output quality deviates unexpectedly.

- If your primary focus is preventive maintenance and minimizing unexpected failures: Combine scheduled calibrations with regular visual inspections of the muffle and heating elements for signs of degradation.

By proactively managing your porcelain furnace's calibration, you ensure the integrity of your work and the efficiency of your operations.

Summary Table:

| Factor | Impact on Calibration Frequency |

|---|---|

| Furnace Age & Muffle Condition | Older units or degraded muffles require more frequent checks. |

| Frequency & Intensity of Use | High-volume, continuous use necessitates quarterly or monthly calibration. |

| Type of Materials Processed | Sensitive materials with strict tolerances may need pre-project calibration. |

Ensure consistent, high-quality porcelain firing with reliable equipment from KINTEK.

An accurately calibrated furnace is the foundation of predictable results, saving you time and money by reducing rework and material waste. KINTEK specializes in premium lab equipment and consumables, serving the precise needs of dental and laboratory professionals.

Let our experts help you maintain peak performance. Contact KINTEK today to discuss your furnace calibration needs and explore our range of durable, precision-engineered solutions.

Visual Guide

Related Products

- 1200℃ Muffle Furnace Oven for Laboratory

- Graphite Vacuum Furnace Negative Material Graphitization Furnace

- Horizontal High Temperature Graphite Vacuum Graphitization Furnace

- 1700℃ Laboratory High Temperature Tube Furnace with Alumina Tube

- Graphite Vacuum Furnace Bottom Discharge Graphitization Furnace for Carbon Materials

People Also Ask

- What is the primary function of a Dental Press Furnace? Fabricate Strong, Aesthetic Dental Restorations

- What is the firing of porcelain in dentistry? The Lab Process for Strong, Life-like Crowns & Veneers

- What is the temperature of a porcelain furnace? Master Sintering for Perfect Results

- What is the temperature of the burnout oven? Master the Multi-Stage Cycle for Flawless Castings

- What are the different types of dental furnaces? Choose the Right Furnace for Your Dental Lab

- What is a key consideration when purchasing a dental furnace? Ensure Material Compatibility for Superior Restorations

- What is the function of a porcelain furnace? Precision Firing for Lifelike Dental Restorations

- Are zirconia crowns biocompatible? The Ultimate Guide to Safe, Metal-Free Dental Restorations