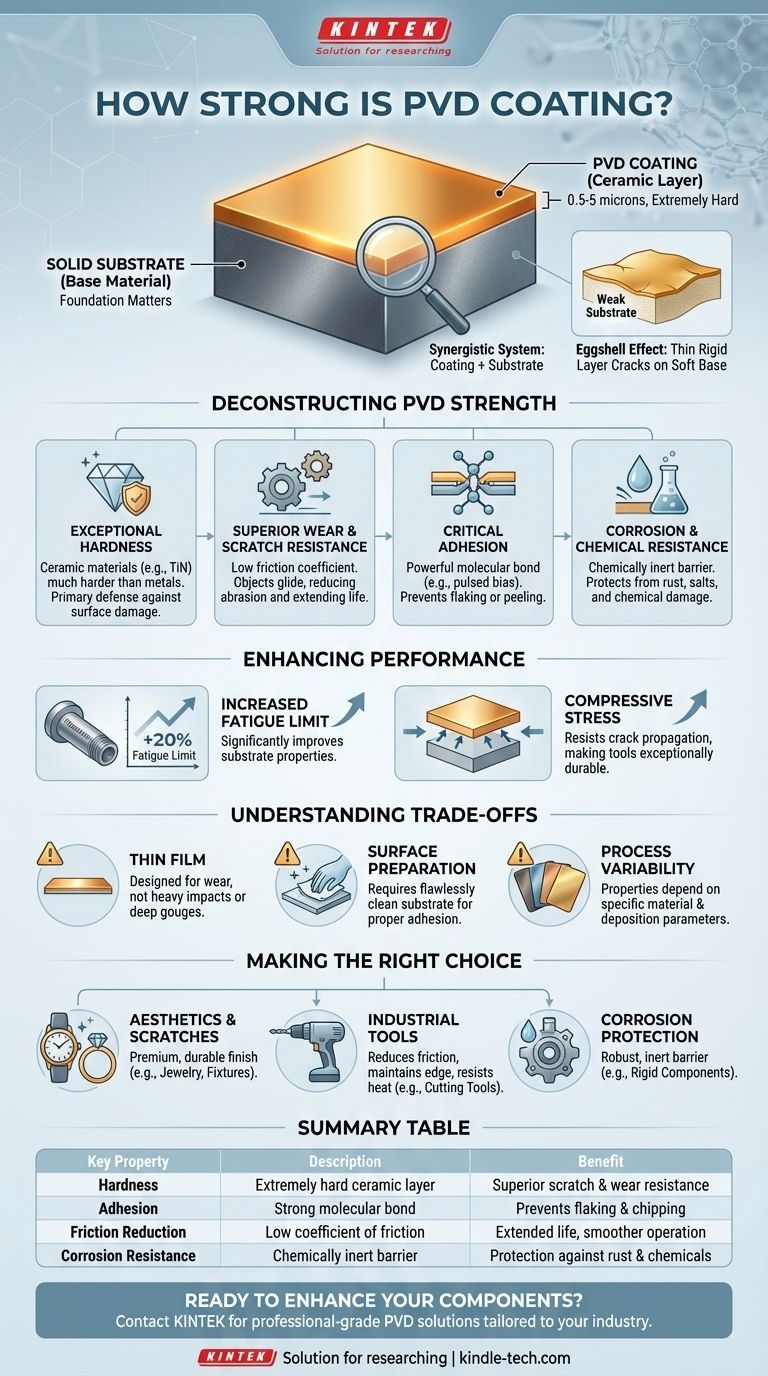

To be precise, the strength of a Physical Vapor Deposition (PVD) coating is not a single value but a combination of properties. It creates an extremely hard, thin ceramic layer on a surface that is highly resistant to wear, corrosion, and friction. The coating's true strength, however, is fundamentally tied to the hardness and preparation of the underlying material it is bonded to.

The core takeaway is that PVD is not a standalone shield; it is a surface-level enhancement. Its remarkable durability comes from forming a synergistic system with the base material, increasing its surface hardness and wear resistance, but it cannot compensate for a weak substrate.

Deconstructing the "Strength" of PVD

When we discuss the "strength" of a PVD coating, we are actually referring to several distinct, measurable characteristics that work together to create a highly durable surface.

Exceptional Hardness

PVD coatings are often ceramic materials like Titanium Nitride (TiN), which are inherently much harder than most metals. This process deposits a very thin—typically 0.5 to 5 microns—but densely packed layer onto the substrate.

This added hardness is the primary defense against surface damage.

Superior Wear and Scratch Resistance

Hardness directly translates to excellent resistance against wear, abrasion, and scratches. The process also significantly reduces the coefficient of friction on the surface.

A lower-friction surface means objects are more likely to glide over it rather than digging in and causing a scratch, dramatically extending the pristine appearance and functional life of the part.

The Critical Role of Adhesion

A coating is only as strong as its bond to the substrate. PVD creates a powerful bond at a molecular level, ensuring the coating does not easily flake, chip, or peel.

Modern PVD processes use technologies like pulsed bias systems to physically drive the coating material into the surface of the substrate, creating an exceptionally strong and integrated bond.

Corrosion and Chemical Resistance

The PVD layer acts as a chemically inert barrier between the substrate and its environment. This protects the underlying metal from oxidation (rust), corrosion from salt, and damage from many chemicals.

It's a Partnership: The Substrate and Coating System

A PVD coating should not be evaluated in isolation. Its performance is entirely dependent on the material it is applied to, creating a composite system where both parts must work together.

The Foundation Matters

Think of PVD as a thin layer of ice. Over a solid granite slab, that ice is incredibly hard and difficult to break. Over soft mud, however, any pressure will deform the mud, and the "strong" ice will crack instantly.

Similarly, applying a hard PVD coating to a soft material like aluminum will not prevent dents. If the base material deforms from an impact, the thin, rigid PVD layer on top may crack—a phenomenon known as the "eggshell effect."

How PVD Enhances Performance

When applied to a suitable substrate, PVD dramatically enhances its inherent properties. For example, a Titanium Nitride (TiN) coating on a high-strength titanium alloy has been shown to increase the fatigue limit by over 20%.

During the cooling phase of the PVD process, the coating forms a state of compressive stress. This internal stress helps to resist the formation and propagation of microscopic cracks, making PVD-coated tools exceptionally durable for demanding tasks like milling.

Understanding the Trade-offs

While highly effective, PVD is not a universal solution. Understanding its limitations is key to using it correctly.

It Is a Thin Film

The coating is exceptionally hard, but it is also exceptionally thin. It is designed to protect against scratches and wear, not to absorb the energy of a heavy impact or prevent a deep gouge that deforms the base metal.

The Importance of Surface Preparation

The performance of PVD is critically dependent on a flawlessly clean and smooth substrate. Any surface imperfections, oils, or contaminants will compromise adhesion and lead to premature failure of the coating.

Not All PVD is Created Equal

The term "PVD" describes a process, not a single material. The final properties—color, hardness, friction coefficient—depend entirely on the specific ceramic material being deposited (e.g., TiN, CrN, AlTiN) and the precise parameters of the deposition process.

Making the Right Choice for Your Application

Use PVD strategically where its specific strengths solve your core problem.

- If your primary focus is aesthetics and scratch resistance (e.g., watches, jewelry, fixtures): PVD is an excellent choice, providing a durable, long-lasting finish with a premium look.

- If your primary focus is industrial tool performance (e.g., drill bits, milling cutters): PVD is essential for increasing tool life by reducing friction, maintaining a sharp cutting edge, and resisting high-temperature wear.

- If your primary focus is corrosion protection on a rigid component: PVD provides a robust and inert barrier that is far more durable than traditional paints or plating.

Ultimately, view PVD not as a simple protective layer, but as a strategic engineering decision to enhance the surface performance of a well-chosen material.

Summary Table:

| Key Property | Description | Benefit |

|---|---|---|

| Hardness | Extremely hard ceramic layer (e.g., TiN) | Superior scratch and wear resistance |

| Adhesion | Strong molecular bond to substrate | Prevents flaking and chipping |

| Friction Reduction | Low coefficient of friction | Extended part life and smoother operation |

| Corrosion Resistance | Chemically inert barrier | Protection against rust and chemicals |

Ready to enhance your components with professional-grade PVD coatings?

KINTEK specializes in advanced lab equipment and consumables, including PVD coating solutions tailored for industries like aerospace, medical devices, and precision tooling. Our expertise ensures your substrates receive optimal surface enhancement for maximum durability and performance.

Contact us today to discuss how our PVD coatings can solve your specific wear, corrosion, or friction challenges!

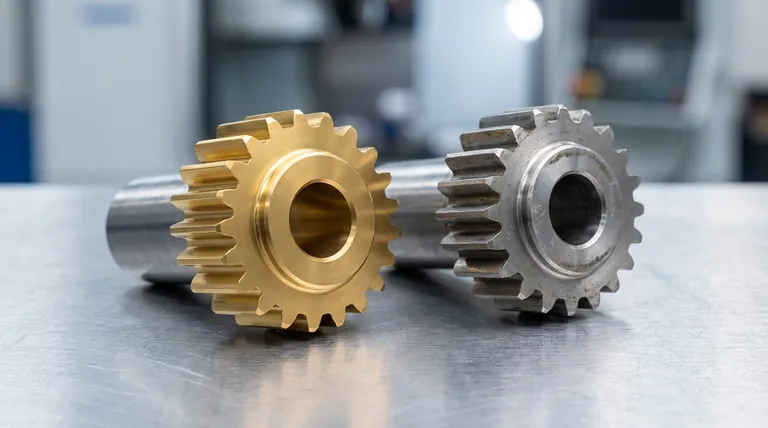

Visual Guide

Related Products

- Custom CVD Diamond Coating for Lab Applications

- RF PECVD System Radio Frequency Plasma-Enhanced Chemical Vapor Deposition RF PECVD

- Vacuum Hot Press Furnace Machine for Lamination and Heating

- Laboratory Muffle Oven Furnace Bottom Lifting Muffle Furnace

- Precision Machined Zirconia Ceramic Ball for Engineering Advanced Fine Ceramics

People Also Ask

- What is diamond coating film? A Thin Layer of Diamond for Extreme Performance

- Is diamond coating worth it? Maximize Component Life and Performance

- How long does diamond coating last? Maximize Lifespan with the Right Coating for Your Application

- How thick is CVD diamond coating? Balancing Durability and Stress for Optimal Performance

- What are diamond coated films? Enhance Materials with Super-Hard, Transparent Layers