In safety-critical systems, yes, a pressure switch is absolutely necessary. It acts as an essential safety device, not just a functional component. In a furnace, for example, it prevents carbon monoxide exposure and potential fires by ensuring the system is operating under safe pressure conditions before allowing combustion to continue.

A pressure switch is fundamentally a gatekeeper. It translates a physical condition—a specific pressure level—into an electrical command, either permitting or halting an operation to ensure both proper function and critical safety.

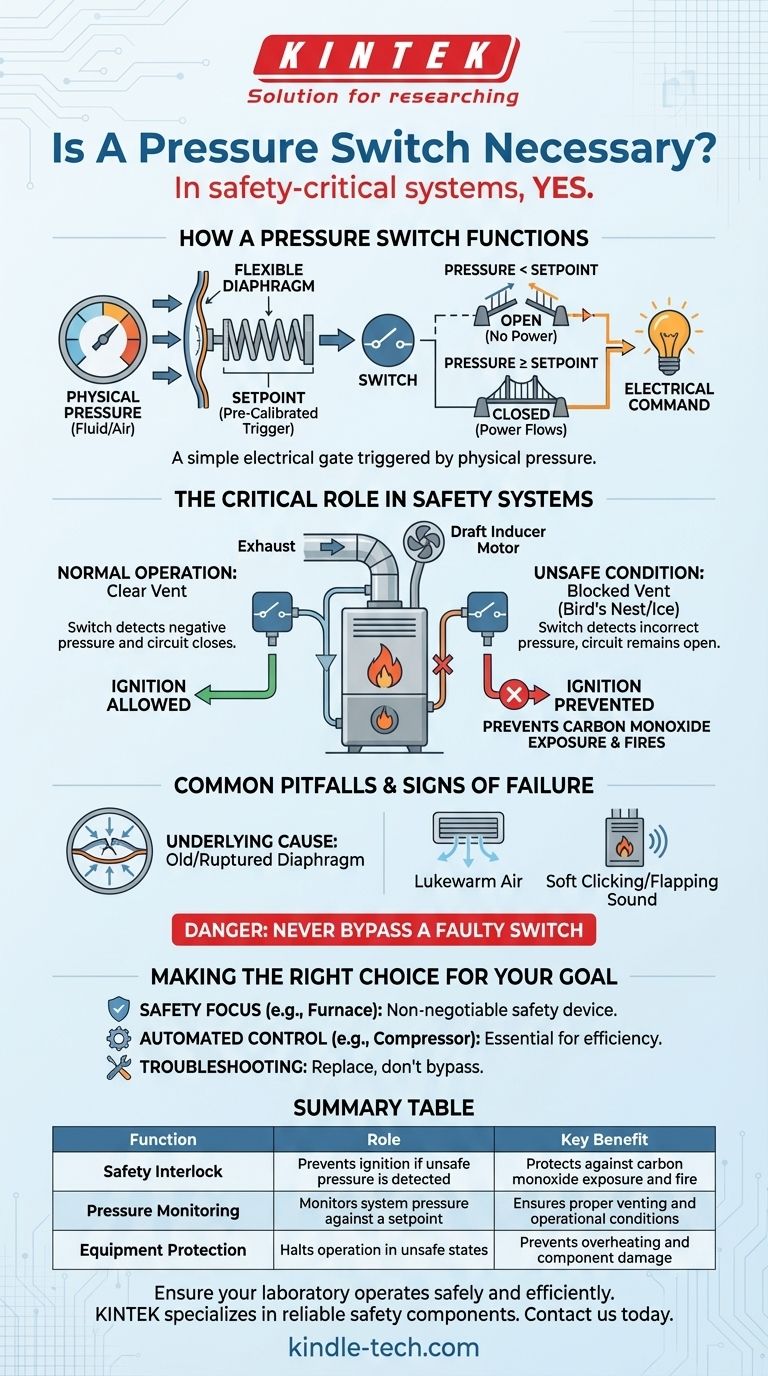

How a Pressure Switch Functions

A pressure switch is a simple but ingenious device that connects a physical system to an electrical one. Its job is to monitor pressure and act when a specific threshold is crossed.

The Core Principle: A Simple Electrical Gate

Think of a pressure switch like a drawbridge for electricity. When the switch is "open," the drawbridge is up, and no power can pass through. When the switch is "closed," the bridge is down, completing the circuit and allowing power to flow to a component.

Actuation by Physical Pressure

The switch doesn't open or close on its own. It relies on pressure from a fluid (like air or water) pushing against a diaphragm inside it. This movement is the key to its operation.

The "Setpoint": A Pre-Calibrated Trigger

Inside the switch, a calibrated spring resists the diaphragm's movement. The switch is designed to actuate only when the pressure becomes strong enough to compress this spring. This pre-determined pressure level is known as the setpoint.

Once the setpoint is reached, the switch flips its state—either closing a normally open (NO) circuit or opening a normally closed (NC) one—to turn a device on or off.

The Critical Role in Safety Systems

While pressure switches are used in many applications, their most vital role is in safety. The modern gas furnace is a perfect example.

Preventing Harmful Gas Exposure

Your furnace must safely vent exhaust gases, including dangerous carbon monoxide, out of your home. The pressure switch's job is to confirm that the vent is clear. It does this by detecting the small amount of negative pressure created by the draft inducer motor.

If the switch doesn't detect the correct pressure—perhaps due to a bird's nest or ice blocking the vent—it will prevent the furnace from igniting. This action directly stops carbon monoxide from building up inside your living space.

Protecting Equipment and Preventing Fires

By ensuring all conditions are correct before operation, the pressure switch also protects the equipment itself. It stops the furnace from attempting to run in an unsafe state that could lead to overheating, component failure, or even a fire.

Common Pitfalls and Signs of Failure

Like any mechanical component, a pressure switch can wear out and fail. Bypassing a faulty switch, even temporarily, is extremely dangerous as it disables a life-saving safety feature.

Symptoms of a Failing Switch

You may have a failing furnace pressure switch if you notice lukewarm air coming from your vents or hear a soft flapping or clicking sound when the furnace attempts to start. These are often signs the switch is failing to close the circuit properly.

The Underlying Cause

Failure is often due to the internal diaphragm becoming old, brittle, or ruptured. When this happens, it can no longer move correctly in response to pressure changes, rendering it unable to do its job.

Making the Right Choice for Your Goal

Understanding the role of a pressure switch is key, whether you are troubleshooting, designing, or simply maintaining a system.

- If your primary focus is safety (e.g., a home furnace): The pressure switch is a non-negotiable safety device that must be functioning correctly at all times.

- If your primary focus is automated control (e.g., an air compressor): The switch is necessary for the system to operate efficiently and automatically without manual intervention.

- If your primary focus is troubleshooting a failed system: Suspecting a faulty pressure switch is valid, but replacing it with the correct part is the only safe solution.

Ultimately, the pressure switch serves as the critical link between safe physical conditions and correct electrical operation.

Summary Table:

| Function | Role | Key Benefit |

|---|---|---|

| Safety Interlock | Prevents ignition if unsafe pressure is detected | Protects against carbon monoxide exposure and fire |

| Pressure Monitoring | Monitors system pressure against a setpoint | Ensures proper venting and operational conditions |

| Equipment Protection | Halts operation in unsafe states | Prevents overheating and component damage |

Ensure your laboratory operates safely and efficiently. KINTEK specializes in lab equipment and consumables, including reliable safety components like pressure switches. Don't compromise on safety—contact us today to find the right solutions for your laboratory needs.

Visual Guide

Related Products

- Warm Isostatic Press WIP Workstation 300Mpa for High Pressure Applications

- Laboratory Vortex Mixer Orbital Shaker Multifunctional Rotation Oscillation Mixer

- 600T Vacuum Induction Hot Press Furnace for Heat Treat and Sintering

- Vacuum Hot Press Furnace Machine for Lamination and Heating

- Vacuum Hot Press Furnace Machine Heated Vacuum Press

People Also Ask

- What are the functions of high-purity quartz balls and quartz sand for catalyst testing? Enhance Reactor Performance

- Why are zirconia grinding jars and balls required for sulfide electrolytes? Prevent Metallic Contamination & Side Reactions

- What is the role of high-temperature stainless steel fixtures in diffusion couple experiments? Ensure Data Integrity

- What is the function of a high-power ultrasonic homogenizer in mixed matrix membranes? Achieve Superior Performance

- What are the main disadvantages associated with Rotary Vane Pumps? Avoid Contamination & High Maintenance Costs

- Why is a programmable temperature controller necessary during the annealing process of manganese coatings?

- Is fused silica the same as quartz? Unlock Superior Optical and Thermal Performance

- What are the common uses of vacuum pumps in laboratories? Essential for Filtration, Evaporation & Analysis