At its core, Hot Isostatic Pressing (HIP) is a materials processing method that uses high temperature and high-pressure gas to improve a material's properties. By subjecting a component to uniform pressure from all directions at elevated temperatures, the process collapses and welds shut internal voids, cracks, and porosity. This results in a final part with significantly increased density, improved mechanical properties, and greater reliability.

The fundamental purpose of HIP is to achieve near-perfect material density. It's a critical tool for either healing internal defects in pre-formed parts or consolidating powders into a fully solid component, unlocking the material's ultimate performance potential.

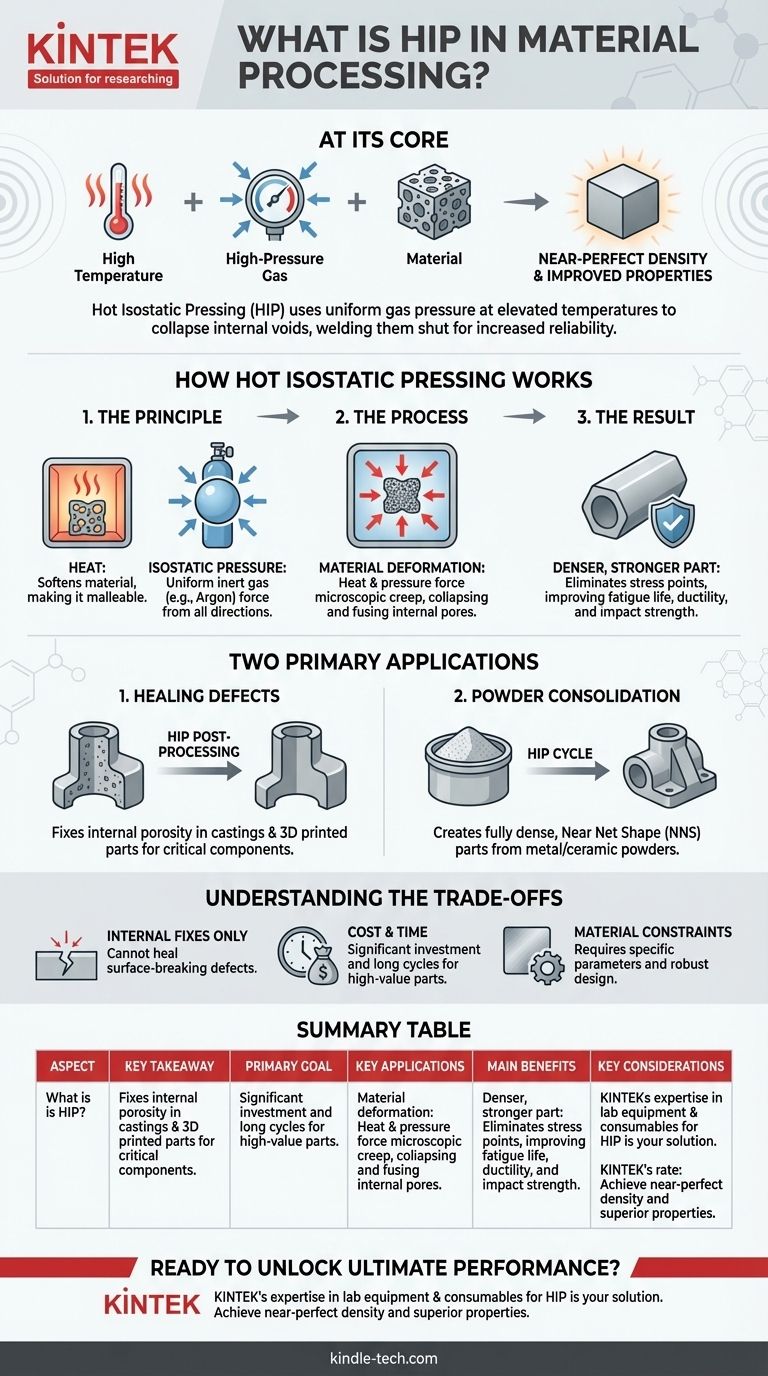

How Hot Isostatic Pressing Works

HIP leverages the principles of thermodynamics and pressure to fundamentally alter a material's internal structure. The "hot" and "isostatic" aspects are equally important.

The Core Principle: Temperature and Pressure

The high temperature brings the material to a state where it is soft and plastic, but below its melting point. This makes it malleable enough for microscopic changes to occur.

Simultaneously, an inert gas (typically Argon) is used to apply extreme, uniform pressure. This is known as isostatic pressure, meaning it is applied equally on all surfaces of the component, eliminating the risk of distortion.

The Process in Action

A component is loaded into a sealed, high-pressure containment vessel. The vessel is heated, and then the inert gas is pumped in and pressurized.

The combination of heat and pressure forces the material to creep and plastically deform on a microscopic scale. This action effectively collapses any internal pores or voids, permanently fusing their surfaces together.

The Result: A Denser, Stronger Part

The primary outcome of HIP is the elimination of internal porosity. By removing these microscopic defects, which act as stress concentration points, the process dramatically improves a material's mechanical properties, including fatigue life, ductility, and impact strength.

The Two Primary Applications of HIP

While the principle is singular, its application falls into two main categories: healing existing parts and creating new ones.

1. Healing Defects in Castings and Additive Parts

Many manufacturing methods, such as metal casting or additive manufacturing (3D printing), can leave behind tiny internal voids. While the part may look perfect, these pores compromise its structural integrity.

HIP is used as a post-processing step to "heal" these defects. This is a common and often mandatory step for critical components where failure is not an option.

2. Consolidating Powders into a Solid

HIP can also be used to create fully dense parts directly from metal, ceramic, or composite powders. The powder is placed into a shaped container or "can," which is then sealed.

During the HIP cycle, the powder particles are fused together, resulting in a solid, near net shape (NNS) component. This is a powerful method for creating complex parts from materials that are difficult to forge or machine.

Understanding the Trade-offs

While powerful, HIP is a specialized process with specific considerations. It is not a universal solution for all material problems.

It Primarily Fixes Internal Defects

HIP is exceptionally effective at closing internal porosity. However, it cannot heal surface-breaking cracks or defects open to the atmosphere, as the pressurized gas would enter the crack, equalizing the pressure and preventing it from closing.

Cost and Cycle Time

HIP equipment is a significant capital investment, and the process itself can take several hours per cycle. This makes it more expensive than many conventional heat treatments and is typically reserved for high-value or performance-critical components.

Material and Design Constraints

The process parameters (temperature and pressure) must be carefully selected based on the specific material being treated. The design of the component must also be able to withstand the process without unwanted distortion.

Making the Right Choice for Your Goal

Deciding whether to specify HIP requires a clear understanding of your component's performance requirements and failure risks.

- If your primary focus is maximizing the reliability of critical components: Use HIP as a post-processing step on castings or 3D printed parts to eliminate internal porosity and significantly increase fatigue life.

- If your primary focus is manufacturing complex shapes from advanced materials: Consider using HIP with powder metallurgy to create fully dense, near net shape parts that would be difficult or impossible to make otherwise.

- If your primary focus is achieving a material's absolute peak properties: HIP is the definitive process for removing the inherent defects that limit strength, ductility, and consistency.

Ultimately, Hot Isostatic Pressing is the tool you turn to when good enough isn't good enough, ensuring your material achieves its maximum theoretical integrity.

Summary Table:

| Aspect | Key Takeaway |

|---|---|

| Primary Goal | Achieve near-perfect material density by eliminating internal porosity. |

| Key Applications | Healing defects in castings/additive parts; consolidating powders into solid components. |

| Main Benefits | Increased fatigue life, improved ductility, greater reliability, and enhanced strength. |

| Key Considerations | Cannot heal surface-breaking defects; involves significant cost and cycle time. |

Ready to unlock the ultimate performance potential of your materials?

If your project demands maximum reliability for critical components or involves manufacturing complex parts from advanced materials, KINTEK's expertise in Hot Isostatic Pressing is your solution. We specialize in providing the lab equipment and consumables necessary to achieve near-perfect density and superior mechanical properties.

Contact our experts today to discuss how HIP can enhance your lab's capabilities and ensure your materials meet the highest standards of integrity.

Visual Guide

Related Products

- Warm Isostatic Press WIP Workstation 300Mpa for High Pressure Applications

- Warm Isostatic Press for Solid State Battery Research

- Manual High Temperature Heated Hydraulic Press Machine with Heated Plates for Lab

- Automatic High Temperature Heated Hydraulic Press Machine with Heated Plates for Lab

- Automatic Laboratory Heat Press Machine

People Also Ask

- What role does Hot Isostatic Pressing (HIP) equipment play in Ti6Al4V-SiCf preparation? Achieve Peak Composite Density

- What is the pressure of hot isostatic pressing? Unlock Full Material Density with High-Pressure HIP

- How long is hot isostatic pressing? Unlocking the Variables That Control Cycle Time

- What are the conditions for hot isostatic pressing? Unlock Maximum Material Density

- What is the sinter HIP process? Achieve Near-Perfect Density in a Single Cycle

- How does hot isostatic pressing work? Achieve Full Density and Superior Material Performance

- How does Hot Isostatic Pressing reduce porosity? Eliminate Internal Voids for Superior Material Density

- How does Hot Isostatic Press (HIP) enhance Si3N4 and h-BN ceramics? Achieving Full Density and Isotropy