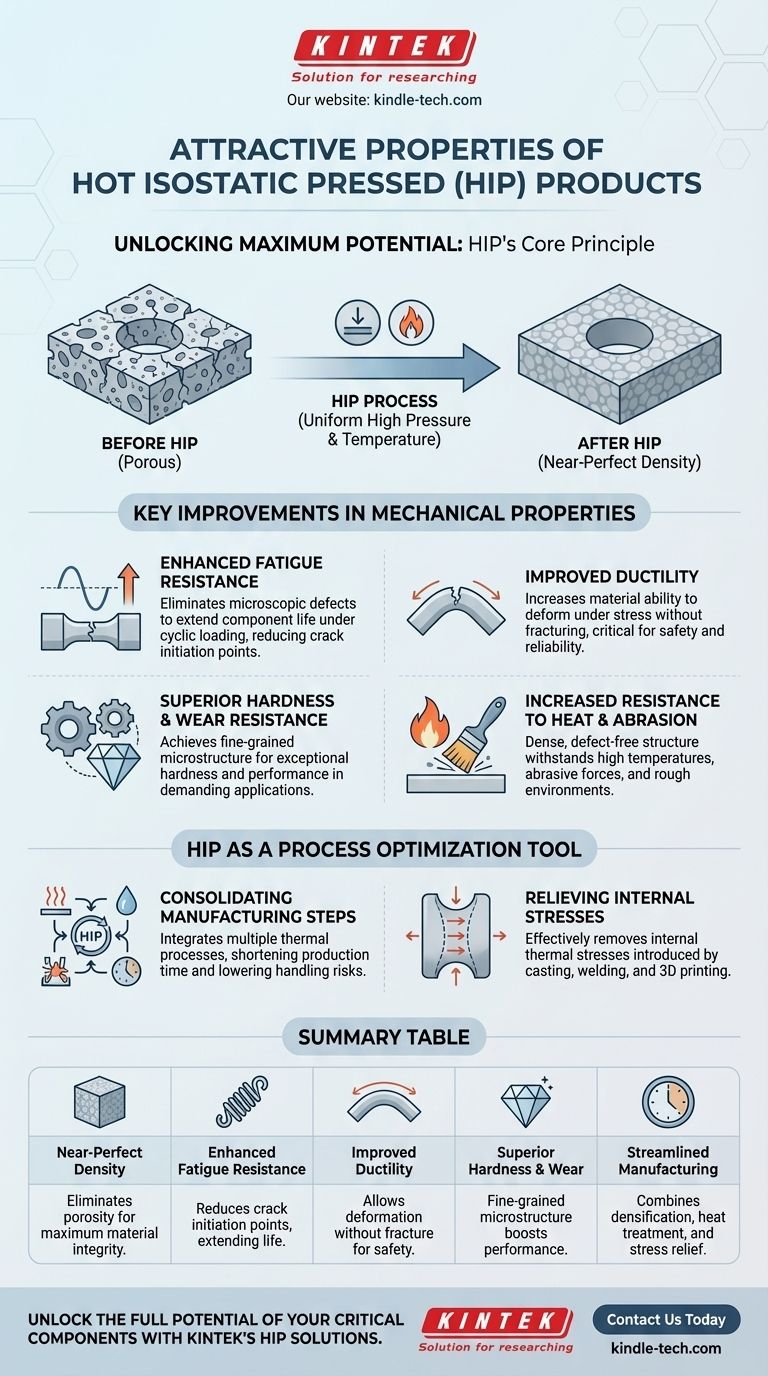

The most attractive properties of products treated with Hot Isostatic Pressing (HIP) are their near-perfect density and the resulting dramatic improvement in mechanical performance. The process uses uniform high pressure and elevated temperature to eliminate internal defects like porosity in castings and 3D-printed parts, leading to superior fatigue resistance, ductility, and overall reliability.

Hot Isostatic Pressing fundamentally transforms a component by healing it from the inside out. By collapsing internal voids, it creates a fully dense, uniform material structure, unlocking the maximum potential performance and reliability for parts in critical applications.

The Core Principle: Eliminating Internal Defects

The primary function of HIP is to remove the internal imperfections that compromise a part's integrity. This healing process is the source of all its subsequent benefits.

Achieving Near-Theoretical Density

HIP subjects a component to uniform pressure from all directions. This immense, evenly distributed force physically collapses internal voids, microporosity, and gas pockets.

The result is a product with density that approaches the absolute theoretical maximum for that material. This is a significant advantage over methods like conventional hot pressing, which may not achieve the same level of densification.

Creating a Uniform Microstructure

For components made through additive manufacturing (3D printing) or sintering, HIP is transformative. It addresses common issues like poor adhesion between printed layers or incomplete bonding between powder particles.

The process fuses these layers and particles together on a microscopic level, creating a homogenous and consistent internal structure throughout the entire part.

Key Improvements in Mechanical Properties

By creating a solid, uniform material, HIP directly enhances the mechanical properties that matter most in demanding applications.

Enhanced Fatigue Resistance and Ductility

Microporosity acts as a starting point for cracks. By eliminating these microscopic defects, HIP significantly improves a part's resistance to fatigue failure under cyclic loading.

This internal integrity also improves ductility, allowing the material to deform under stress without fracturing, a critical property for safety and reliability.

Superior Hardness and Wear Resistance

In applications like precision tooling, HIP creates products with exceptional hardness and wear resistance.

Because the process can be performed at lower temperatures and for shorter durations than some alternatives, it prevents the growth of coarse grains. This results in a fine-grained microstructure that boosts hardness and performance, especially for precision rolls and wear parts.

Increased Resistance to Heat and Abrasion

The dense, defect-free structure of a HIPed component is inherently more robust. This makes the final product better equipped to withstand rough environments, including high temperatures, abrasive forces, and general wear and tear.

HIP as a Process Optimization Tool

Beyond improving the final product, the HIP process itself offers compelling advantages for manufacturing efficiency.

Consolidating Manufacturing Steps

Modern HIP systems can integrate multiple thermal processes into a single cycle. A component can undergo heat treatment, high-pressure quenching, and aging within the HIP unit.

This consolidation reduces the total number of manufacturing steps, shortens production time, and lowers the risk of handling-related damage between processes.

Relieving Internal Stresses

Manufacturing processes like casting, welding, and 3D printing often introduce significant internal thermal stresses. HIP effectively relieves these stresses, improving the dimensional stability and overall performance of the finished part.

Making the Right Choice for Your Goal

Ultimately, the decision to use HIP depends on the specific requirements of your component and its application.

- If your primary focus is ultimate reliability and performance: HIP is the definitive choice for eliminating internal defects to maximize fatigue life and ductility in critical components.

- If your primary focus is qualifying additively manufactured parts: HIP is an essential post-processing step to heal porosity and poor layer bonding, turning a near-net shape part into a fully functional, high-performance component.

- If your primary focus is manufacturing efficiency for complex parts: HIP can streamline your production by combining densification, heat treatment, and stress relief into a single, controllable cycle.

By understanding these properties, you can leverage Hot Isostatic Pressing to produce components that are not just manufactured, but perfected.

Summary Table:

| Property | Benefit |

|---|---|

| Near-Perfect Density | Eliminates porosity and internal voids for maximum material integrity. |

| Enhanced Fatigue Resistance | Reduces crack initiation points, extending component life under cyclic loads. |

| Improved Ductility | Allows deformation without fracture for greater safety and reliability. |

| Superior Hardness & Wear Resistance | Fine-grained microstructure boosts performance in demanding applications. |

| Streamlined Manufacturing | Combines densification, heat treatment, and stress relief in one cycle. |

Unlock the full potential of your critical components with KINTEK's HIP solutions. Whether you're in aerospace, medical, or additive manufacturing, our advanced lab equipment and consumables ensure your parts achieve perfect density and superior mechanical properties. Contact us today to discuss how HIP can transform your manufacturing process and deliver unmatched reliability.

Visual Guide

Related Products

- Warm Isostatic Press WIP Workstation 300Mpa for High Pressure Applications

- Warm Isostatic Press for Solid State Battery Research

- Manual High Temperature Heated Hydraulic Press Machine with Heated Plates for Lab

- 24T 30T 60T Heated Hydraulic Press Machine with Heated Plates for Laboratory Hot Press

- Automatic Heated Hydraulic Press Machine with Heated Plates for Laboratory Hot Press

People Also Ask

- How long is hot isostatic pressing? Unlocking the Variables That Control Cycle Time

- What is the sinter HIP process? Achieve Near-Perfect Density in a Single Cycle

- What is the hot isostatic pressing cycle? A Guide to HIP for Superior Material Integrity

- How do warm isostatic presses improve dry electrode performance? Enhance ASSB Conductivity with Heat & Pressure

- What is the purpose of using a high-vacuum diffusion pump system for pre-treating powder capsules in HIP? Avoid PPBs

- What is the temperature and pressure for hot isostatic pressing? Achieve 100% Dense, High-Performance Materials

- How does Hot Isostatic Pressing reduce porosity? Eliminate Internal Voids for Superior Material Density

- How long does hot isostatic pressing take? From Hours to Days, Unpacking the Full HIP Cycle