At its core, Hot Isostatic Pressing (HIP) is an energy-intensive process. The exact energy consumption is not a single figure but varies significantly based on the size of the equipment, the specific materials being processed, and the required temperature and pressure settings. However, viewing its energy use in isolation is a common mistake.

The critical insight is not the energy consumed by the HIP cycle itself, but its potential to reduce total energy consumption across your entire manufacturing workflow by consolidating multiple heat treatment and processing steps into a single, efficient operation.

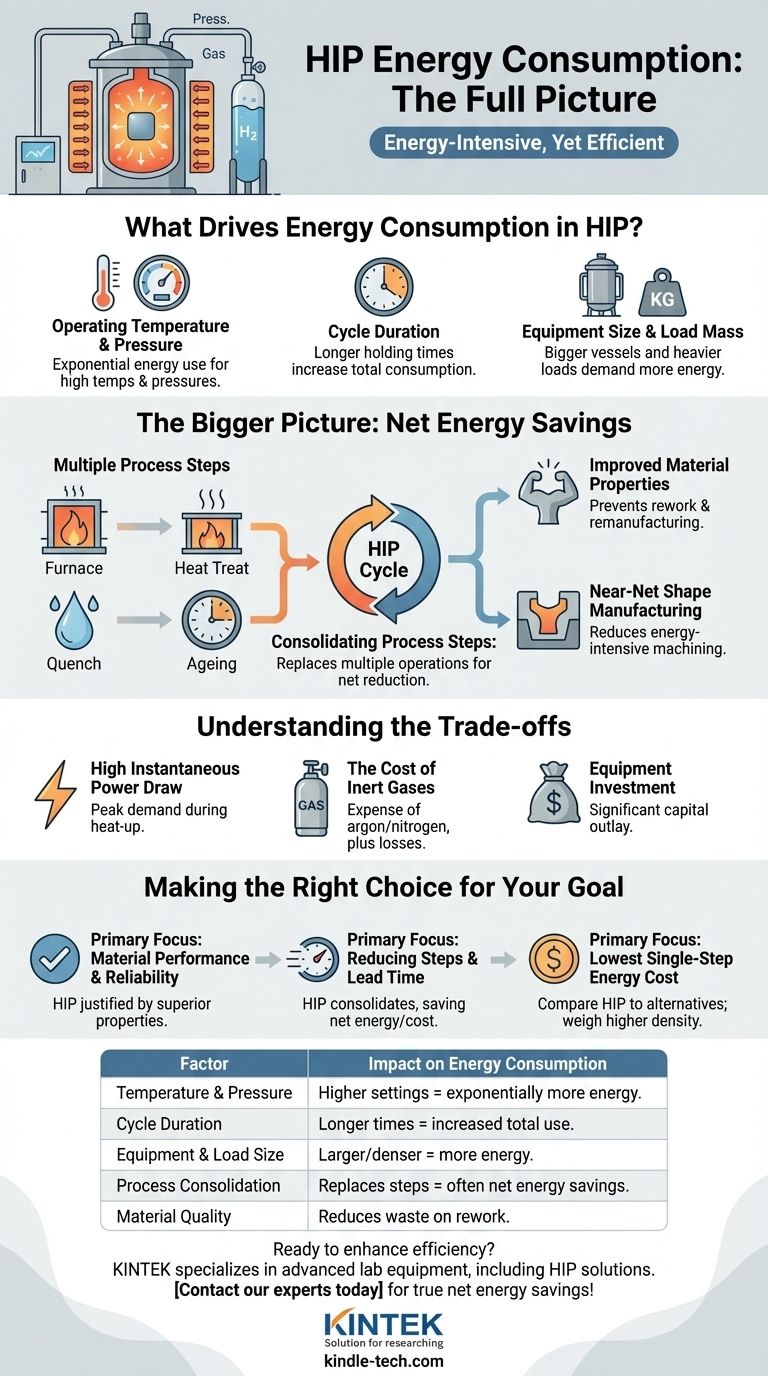

What Drives Energy Consumption in HIP?

The total energy required for a Hot Isostatic Pressing cycle is a direct function of several key operational parameters. Understanding these factors is essential to evaluating its true cost.

Operating Temperature and Pressure

The primary energy draw comes from the electric heaters needed to bring the vessel and its contents to the target temperature, which can be extremely high.

Simultaneously, energy is required to pressurize the inert gas (typically argon) that applies uniform pressure to the components. Higher temperatures and pressures demand exponentially more energy.

Cycle Duration

A typical HIP cycle consists of three phases: heating, holding (soaking) at the target temperature and pressure, and cooling.

Longer holding times, necessary for full densification of certain materials or large parts, directly increase total energy consumption.

Equipment Size and Load Mass

Larger HIP vessels require significantly more energy to heat their internal volume and thicker walls.

Furthermore, the thermal mass of the parts being processed plays a crucial role. A larger or denser load requires more energy to reach and maintain the target temperature.

The Bigger Picture: Net Energy Savings

While the HIP process itself consumes a lot of power, its real value often lies in making the entire production chain more efficient.

Consolidating Process Steps

This is the most significant factor. HIP can often combine sintering, heat treatment, quenching, and aging into a single cycle.

By eliminating the need for multiple separate furnace operations, HIP can lead to a substantial net reduction in total energy usage, production time, and part handling.

Improving Material Properties

The process dramatically improves material properties like density, ductility, and fatigue resistance, particularly in additively manufactured or cast parts.

This enhanced quality can prevent part failure, reduce the need for rework, and eliminate the energy-intensive process of remanufacturing defective components.

Enabling Near-Net Shape Manufacturing

HIP is a key part of powder metallurgy, which creates parts very close to their final dimensions (near-net shape).

This reduces or eliminates the need for subsequent energy-intensive machining operations, saving both energy and raw material.

Understanding the Trade-offs

Adopting HIP requires a clear understanding of its operational costs and requirements beyond just the energy for a single cycle.

High Instantaneous Power Draw

HIP systems have a high peak power demand, especially during the initial heat-up phase. This can have implications for a facility's electrical infrastructure.

The Cost of Inert Gases

The process relies on expensive inert gases like argon or nitrogen as the pressure medium. While these gases are typically recycled, there are always some losses, which contribute to the overall operational cost.

Equipment Investment

Hot isostatic pressing equipment is a significant capital investment. The energy costs must be evaluated in the context of this initial outlay and the high value of the components being produced.

Making the Right Choice for Your Goal

Evaluating HIP's energy consumption requires looking beyond the single machine and at your entire production workflow.

- If your primary focus is ultimate material performance and reliability: The energy cost of HIP is almost always justified by the elimination of internal porosity and the creation of a uniform microstructure.

- If your primary focus is reducing total manufacturing steps and lead time: HIP is a powerful tool for process consolidation, which often results in a net energy and cost savings.

- If your primary focus is the lowest possible energy cost for a single densification step: You must carefully compare HIP to alternatives like conventional hot pressing, weighing the higher density and superior properties achieved by HIP against its energy profile.

Ultimately, the decision to use HIP is a strategic one, where the energy investment is weighed against unparalleled improvements in material quality and overall process efficiency.

Summary Table:

| Factor | Impact on Energy Consumption |

|---|---|

| Temperature & Pressure | Higher settings require exponentially more energy. |

| Cycle Duration | Longer holding times directly increase total energy use. |

| Equipment & Load Size | Larger vessels and denser loads demand more energy to heat. |

| Process Consolidation | Replaces multiple steps, often leading to net energy savings. |

| Material Quality | Reduces energy wasted on rework and remanufacturing. |

Ready to evaluate how HIP can enhance your lab's efficiency and material performance? KINTEK specializes in advanced lab equipment, including hot isostatic pressing solutions, to help you consolidate processes, reduce waste, and achieve superior material properties. Contact our experts today to discuss your specific application and discover the true net energy savings for your workflow!

Visual Guide

Related Products

- Warm Isostatic Press WIP Workstation 300Mpa for High Pressure Applications

- Anti-Cracking Press Mold for Lab Use

- Vacuum Hot Press Furnace Machine for Lamination and Heating

- Laboratory Sterilizer Lab Autoclave Vertical Pressure Steam Sterilizer for Liquid Crystal Display Automatic Type

- Variable Speed Peristaltic Pump

People Also Ask

- What is the process of bio-oil production and manufacturing? From Biomass to Advanced Biofuel

- What are the surface protection techniques? Enhance Durability and Performance for Your Components

- What are the limitations of the IR spectroscopy? Understanding Its Boundaries for Accurate Analysis

- How do ultrasonic cell disruptors or dispersion equipment function during ZIF-8 synthesis? Master Acoustic Cavitation

- What are the limitations of XRF? Understanding Its Boundaries for Accurate Elemental Analysis

- What is sputtering rate? Master the Key to Controlling Thin Film Deposition Speed

- How does temperature control influence green nanoparticle synthesis? Achieve Precision with High-Tech Stirrers

- What is the process of vim var melting? Master Vim Variable Scopes for Bug-Free Scripting