In the context of healthcare regulation, yes, an autoclave is absolutely considered a medical device. When an autoclave is intended for use in sterilizing instruments, equipment, or supplies for human medical application, regulatory bodies classify it as such to enforce strict standards for performance and patient safety.

The crucial distinction is not the technology itself, but its intended use. An autoclave becomes a regulated medical device when it is used for sterilizing healthcare instruments, subjecting it to rigorous design, maintenance, and validation standards that non-medical versions do not require.

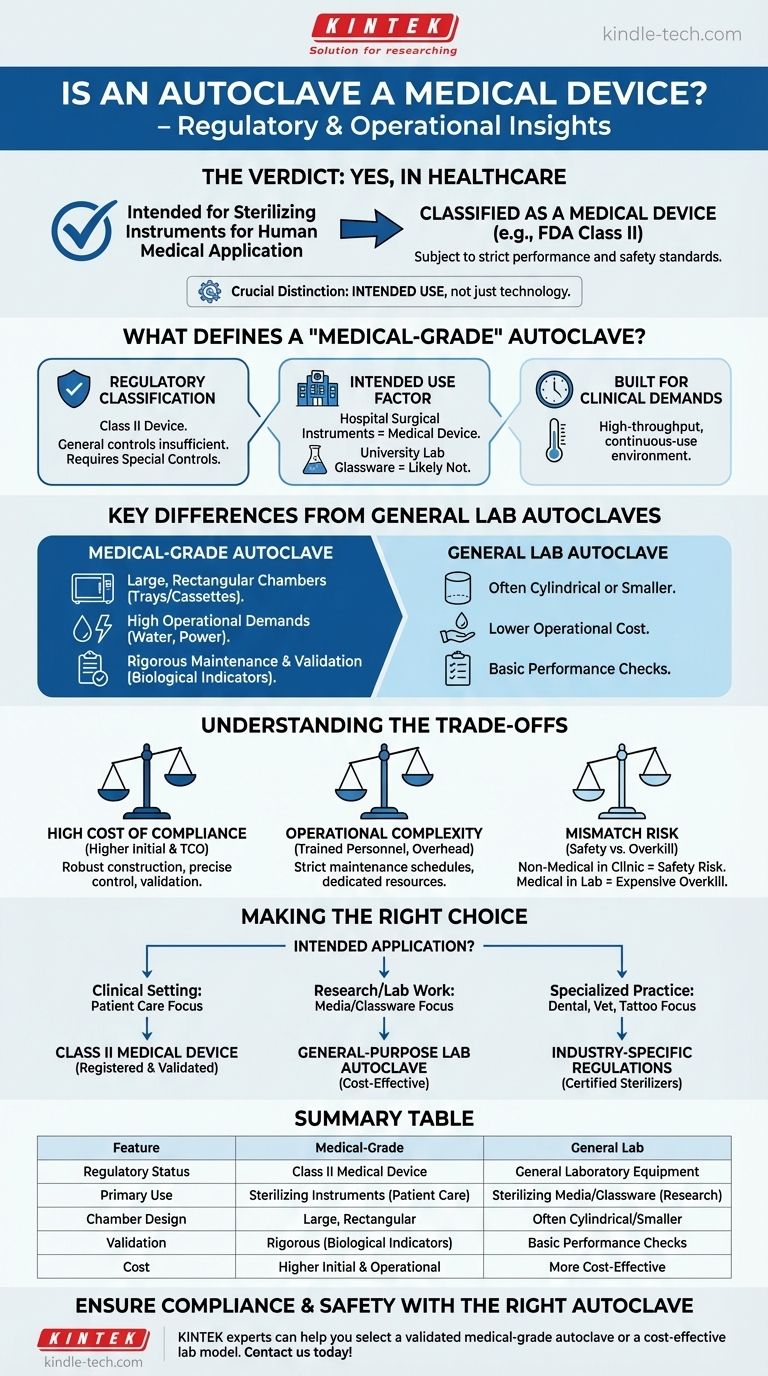

What Defines a "Medical-Grade" Autoclave?

The classification as a medical device is a formal designation that carries significant implications for the machine's design, operation, and oversight.

The Role of Regulatory Classification

Regulatory agencies, such as the FDA in the United States, typically categorize sterilizers as Class II medical devices. This classification signifies that general controls are insufficient to provide a reasonable assurance of safety and effectiveness, requiring special controls to be in place.

Intended Use is the Deciding Factor

The key factor in this classification is "intended use." An autoclave used to sterilize surgical instruments in a hospital is a medical device. A nearly identical machine used to sterilize glassware in a university research lab would likely not be.

Built for Demanding Clinical Environments

Medical-grade autoclaves are specifically engineered for the high-throughput, continuous-use environment of a hospital or surgical center. Their design and construction reflect these demanding operational needs.

Key Differences from Non-Medical Autoclaves

While the principle of steam sterilization is the same, medical-grade autoclaves differ significantly in their construction, operational requirements, and cost.

Design and Capacity

Medical autoclaves often feature large, rectangular chambers. This design is optimized to efficiently accommodate the standardized trays and cassettes used for surgical instruments, maximizing throughput.

High Operational Demands

These devices are resource-intensive. They are designed to run almost constantly, consuming thousands of gallons of water and requiring significant electrical power to maintain the necessary temperature and pressure for repeated cycles.

Rigorous Maintenance and Validation

Medical devices are subject to demanding maintenance and validation protocols. This involves regular, documented servicing and routine testing with biological indicators to legally prove that the machine is achieving complete sterility, a core requirement for patient safety.

Understanding the Trade-offs

The stringent requirements for medical-grade autoclaves create a clear set of trade-offs that are critical to understand.

The High Cost of Compliance

The robust construction, precise control systems, and regulatory validation required for medical device classification result in a significantly higher initial cost and total cost of ownership compared to general-purpose lab sterilizers.

Operational Complexity and Overhead

The necessary maintenance schedules and validation testing require trained personnel and dedicated resources. This adds a layer of operational complexity and ongoing expense that is non-negotiable in a clinical setting.

Mismatching the Tool to the Task

Using a non-medical autoclave for a medical purpose is a serious regulatory violation and poses a direct risk to patient safety. Conversely, using a costly medical-grade unit for simple lab media preparation is often an unnecessary and expensive overkill.

Making the Right Choice for Your Application

Selecting the correct type of autoclave is a critical decision based entirely on its intended application and the regulatory environment.

- If your primary focus is patient care in a clinical setting: You must use a Class II medical device autoclave that is registered with the appropriate regulatory body and meets all standards for performance and validation.

- If your primary focus is research or non-medical laboratory work: A general-purpose or lab-grade autoclave will be far more cost-effective and is designed to meet the needs of sterilizing media and glassware without the medical regulatory burden.

- If your primary focus is a specialized practice (e.g., dental, veterinary, tattoo): You must adhere to your specific industry's regulations, which often require certified sterilizers that prove spore-kill effectiveness for instrument reprocessing.

Ultimately, understanding this classification is fundamental to ensuring both regulatory compliance and the absolute safety of the people you serve.

Summary Table:

| Feature | Medical-Grade Autoclave | General Lab Autoclave |

|---|---|---|

| Regulatory Status | Class II Medical Device | General Laboratory Equipment |

| Primary Use | Sterilizing instruments for patient care | Sterilizing media, glassware for research |

| Chamber Design | Large, rectangular for instrument trays | Often cylindrical or smaller |

| Validation Required | Rigorous, with biological indicators | Basic performance checks |

| Cost | Higher initial and operational cost | More cost-effective for lab use |

Ensure full compliance and patient safety with the right autoclave for your needs. KINTEK specializes in lab equipment and consumables, serving the precise needs of laboratories and clinical settings. Our experts can help you select a validated medical-grade autoclave or a cost-effective lab model perfectly suited to your application. Contact us today to discuss your sterilization requirements!

Visual Guide

Related Products

- Desktop Fast Laboratory Autoclave Sterilizer 35L 50L 90L for Lab Use

- Portable High Pressure Laboratory Autoclave Steam Sterilizer for Lab Use

- Portable Digital Display Automatic Laboratory Sterilizer Lab Autoclave for Sterilization Pressure

- Laboratory High Pressure Steam Sterilizer Vertical Autoclave for Lab Department

- Laboratory High Pressure Horizontal Autoclave Steam Sterilizer for Lab Use

People Also Ask

- What autoclave is used for sterilization? The Definitive Guide to Steam Sterilization

- What are the different types of autoclaves in microbiology? Gravity vs. Pre-Vacuum Explained

- What is the temperature of autoclave in microbiology lab? Achieve Sterile Conditions with 121°C

- What should be autoclaved in a lab? A Guide to Safe and Effective Sterilization

- What is autoclave in laboratory? Achieve Total Sterility for Your Lab