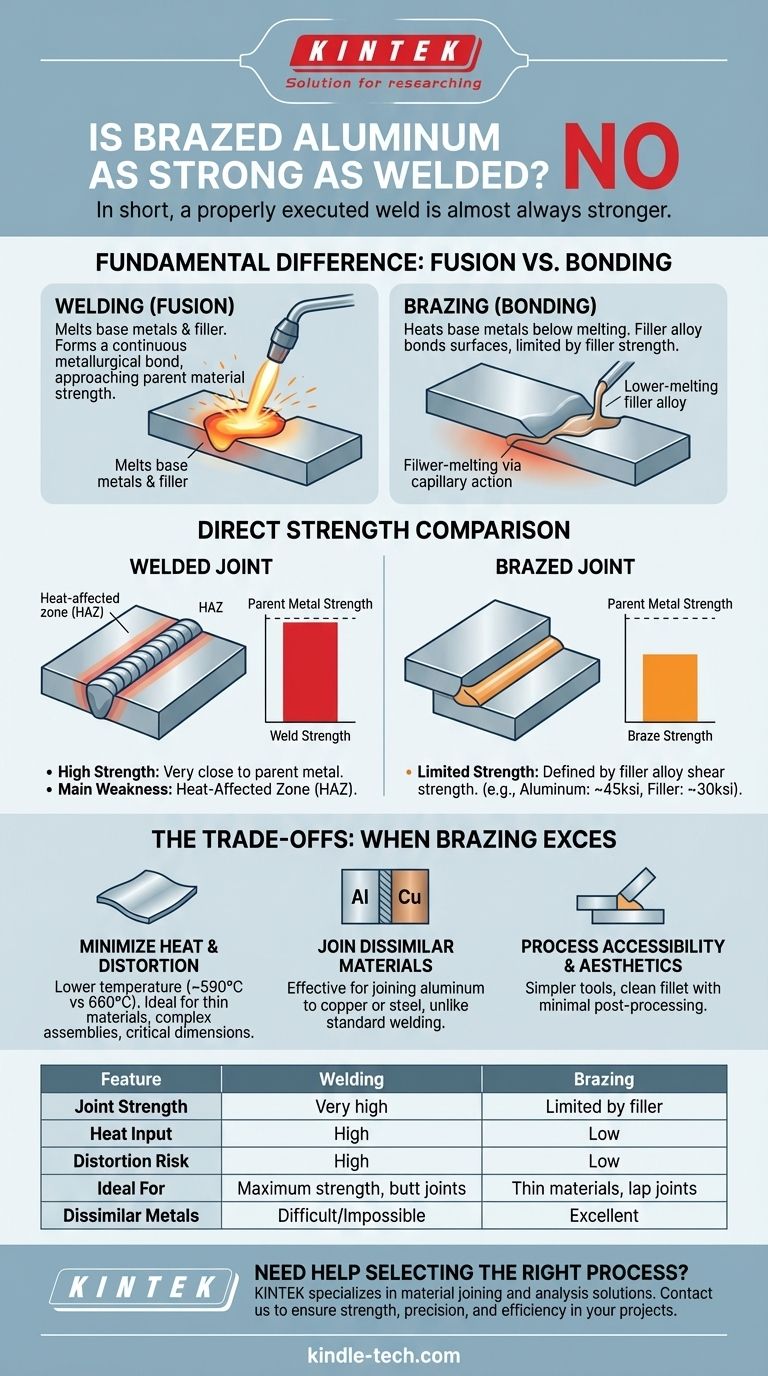

In short, no. A properly executed aluminum weld is almost always stronger than a brazed aluminum joint. Welding fuses the base metals together, creating a continuous metallurgical bond that can approach the strength of the parent material itself. Brazing, by contrast, joins parts using a filler metal with a lower melting point, meaning the joint's ultimate strength is limited by the strength of the weaker filler alloy.

The choice between welding and brazing aluminum is not a simple question of which is "stronger." It is a strategic engineering decision. Welding provides maximum joint strength, while brazing offers superior control over heat distortion, making it the better choice for thin materials, complex assemblies, and joining dissimilar metals.

The Fundamental Difference: Melting vs. Bonding

To understand the strength difference, you must first understand the core distinction between the two processes. They operate on entirely different principles.

How Welding Works

Welding is a process of fusion. It uses a high-temperature source, like a TIG torch, to melt the edges of the aluminum base parts and a compatible filler rod together. This molten pool solidifies to form a single, continuous piece of metal. The goal is a homogenous joint that is, for all intents and purposes, part of the original material.

How Brazing Works

Brazing is a process of adhesion at a microscopic level. It heats the base metals to a temperature below their melting point while melting a specialized brazing filler alloy into the joint. This molten filler is drawn between the closely fitted surfaces by capillary action, creating a strong, bonded connection once it cools. The base metals are never melted.

A Direct Strength Comparison

The strength of the final joint is dictated by the process used and the materials involved.

The Strength of a Welded Joint

A high-quality aluminum weld can achieve a strength that is very close to that of the parent metal. The primary point of weakness is the Heat-Affected Zone (HAZ)—the area of base metal surrounding the weld that was heated but not melted. In this zone, the heat can alter the temper of the aluminum, slightly reducing its strength compared to the unaffected base metal.

The Strength of a Brazed Joint

The strength of a brazed joint is limited by the shear strength of the brazing filler alloy. For aluminum, these filler alloys are inherently weaker than most structural aluminum alloys. For example, a common 6061-T6 aluminum alloy has a tensile strength of around 45,000 psi, whereas an aluminum-silicon brazing filler might have a strength closer to 30,000 psi.

The Critical Role of Joint Design

This difference dictates how joints should be designed. Welding is effective for butt joints, where two pieces are placed edge-to-edge. Brazing is significantly stronger in lap joints or sleeve joints, which maximize the surface area for the filler metal to bond to. This changes the force from a tensile pull to a shear stress across a large area, playing to brazing's strengths.

Understanding the Trade-offs: When Brazing Is the Superior Choice

If welding is stronger, why would anyone ever braze aluminum? Because maximum strength is not the only—or even the most important—factor in many applications.

Minimizing Heat and Distortion

This is the most significant advantage of brazing. Aluminum's melting point is around 1220°F (660°C), while aluminum brazing occurs at approximately 1100°F (590°C). This lower temperature drastically reduces the risk of warping and distortion, making it the ideal choice for thin-gauge sheet metal, tubing, and complex assemblies where dimensional stability is critical.

Joining Dissimilar Materials

Brazing is exceptionally effective at joining aluminum to other metals, such as copper or steel. Standard welding processes cannot do this due to the vast differences in melting points and metallurgy. This makes brazing essential in manufacturing components like heat exchangers and air conditioning coils.

Process Accessibility and Aesthetics

While TIG welding aluminum requires a high degree of skill and expensive AC-capable equipment, torch brazing can be done with much simpler and more affordable tools. Furthermore, a well-executed brazed joint produces a very clean, neat fillet that often requires no post-processing or grinding, unlike a weld bead.

Making the Right Choice for Your Application

Selecting the correct method requires you to define your project's most critical priority.

- If your primary focus is maximum structural strength and load-bearing capacity: Choose welding, as it creates a stronger, more homogenous joint capable of handling higher stress.

- If your primary focus is minimizing distortion on thin materials or complex shapes: Choose brazing for its low heat input and superior dimensional control.

- If your primary focus is joining aluminum to a different metal (like copper): Brazing is your only viable and effective option.

- If your primary focus is a clean, aesthetic joint with minimal finishing: Brazing often yields a neater result that is ready to use without further work.

Ultimately, understanding these fundamental differences empowers you to select the process that delivers not just a connection, but the right performance for your specific engineering goal.

Summary Table:

| Feature | Welding | Brazing |

|---|---|---|

| Joint Strength | Very high (approaches parent metal) | Limited by filler alloy strength |

| Heat Input | High (melts base metal) | Low (base metal not melted) |

| Distortion Risk | High | Low |

| Ideal For | Maximum strength, butt joints | Thin materials, complex shapes, lap joints |

| Dissimilar Metals | Difficult or impossible | Excellent (e.g., aluminum to copper) |

Need help selecting the right aluminum joining process for your application? KINTEK specializes in providing advanced laboratory equipment and consumables, including solutions for material joining and analysis. Our experts can help you choose the best method to ensure strength, precision, and efficiency in your projects. Contact us today to discuss your specific needs and discover how KINTEK can support your laboratory's success!

Visual Guide

Related Products

- Vacuum Hot Press Furnace Heated Vacuum Press Machine Tube Furnace

- Vacuum Hot Press Furnace Machine Heated Vacuum Press

- 600T Vacuum Induction Hot Press Furnace for Heat Treat and Sintering

- Vacuum Hot Press Furnace Machine for Lamination and Heating

- Heated Hydraulic Press Machine with Heated Plates for Vacuum Box Laboratory Hot Press

People Also Ask

- What are the advantages of using a Vacuum Hot-Pressing Furnace for Ti-6Al-4V? Achieve Forged-Like Strength & Purity

- How does a vacuum hot-press sintering furnace produce high-density Mo-Na alloy targets? Precision Thermal Engineering

- Why is a 10^-2 Pa vacuum required for NiCr-based composites? Ensure Purity in Vacuum Hot Pressing

- How does Vacuum Hot Pressing densify W-Si alloys? Master Mechanical Force for High-Density Alloys

- Why is the use of a vacuum hot pressing furnace essential for CrFeMoNbZr targets? Ensure Full Density & Chemical Purity