In many production scenarios, brazing is less expensive than welding. This is primarily due to lower labor and finishing costs, especially in high-volume applications, even though brazing filler metals can sometimes be more costly than welding consumables. The final cost, however, depends entirely on the specific application, materials, and production volume.

The question of cost is not about the sticker price of filler metal but about the total cost of a finished part. Brazing often proves more economical by reducing process time, enabling automation, and eliminating costly secondary operations like grinding and finishing.

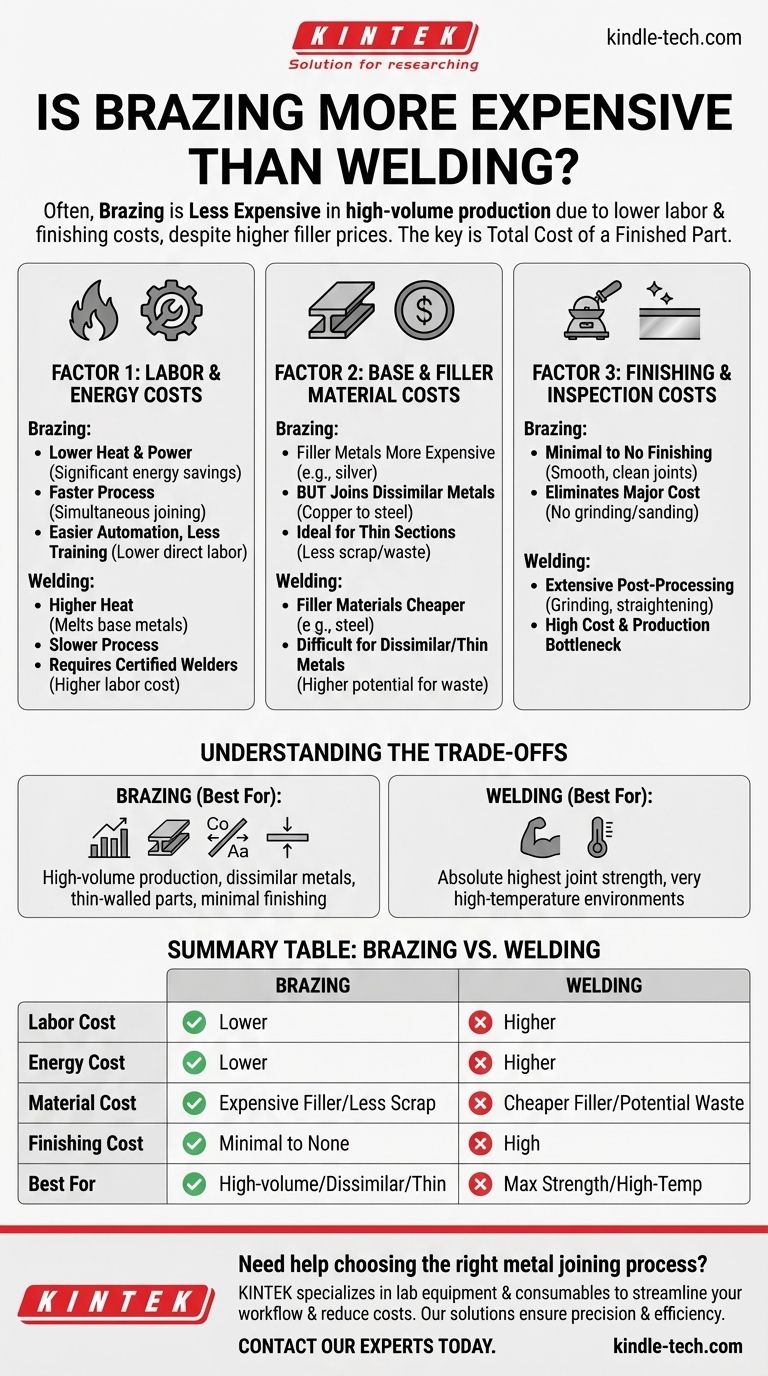

How to Compare True Costs: Brazing vs. Welding

To understand the economics, you must look beyond the process itself and analyze the entire manufacturing workflow. The cost is driven by three main factors: labor, materials, and post-processing.

Factor 1: Labor and Energy Costs

Brazing generally requires less heat and power than welding. The base metals are not melted, only the filler metal is, resulting in significant energy savings per joint.

This lower temperature requirement also means the process can be faster. In many cases, especially with furnace brazing, hundreds or thousands of parts can be joined simultaneously.

Furthermore, brazing is often easier to automate and can be performed by operators with less specialized training than a certified welder, leading to lower direct labor costs.

Factor 2: Base and Filler Material Costs

Welding filler materials are typically based on steel and are relatively inexpensive. Brazing filler metals, particularly those containing silver, can be significantly more expensive per pound.

However, brazing excels at joining dissimilar metals (e.g., copper to steel), which can be difficult or impossible to weld. In these cases, brazing is the only cost-effective option.

Because brazing does not melt the base metals, it is also ideal for joining very thin metal sections without distortion or burn-through, reducing scrap rates and material waste.

Factor 3: Finishing and Inspection Costs

Welded joints often require extensive and costly secondary operations. These include grinding, sanding, and straightening to correct for distortion caused by high heat.

Brazed joints are typically smooth, clean, and neat as-formed. They require little to no post-process finishing, which eliminates a major cost and production bottleneck. This is one of the most significant, yet often overlooked, economic advantages of brazing.

Understanding the Trade-offs

Choosing a joining method based on cost alone is a mistake. The technical requirements of the final product are paramount.

When Welding is the Better Choice

Welding creates a single, fused metallurgical structure. For applications demanding the absolute highest joint strength or performance in very high-temperature environments, welding is often the only suitable choice.

If you are performing a simple repair or fabricating a one-off item, the lower setup cost of a basic welding process may be more economical than sourcing brazing materials and equipment.

Limitations of Brazing

The primary limitation of brazing is the service temperature of the final part. The brazed joint will fail if heated close to the filler metal's melting point.

While strong, a brazed joint is typically not as strong as a properly executed welded joint because it relies on adhesion between the filler and base metals rather than a complete fusion.

Making the Right Choice for Your Goal

To select the most economical process, evaluate your project's primary objective.

- If your primary focus is high-volume production and minimal finishing: Brazing is almost always more cost-effective due to its speed, potential for automation, and elimination of secondary operations.

- If your primary focus is maximum joint strength and high-temperature performance: Welding is the necessary and correct choice, and its higher potential cost is justified by the performance requirements.

- If your primary focus is joining dissimilar metals or thin-walled parts: Brazing provides a reliable, low-distortion solution that is often more economical than specialized welding procedures.

Ultimately, understanding the total cost of production—from initial prep to the finished part—is the key to making the most profitable decision.

Summary Table:

| Factor | Brazing | Welding |

|---|---|---|

| Labor Cost | Lower (easier automation, less training) | Higher (requires certified welders) |

| Energy Cost | Lower (less heat required) | Higher (base metals melted) |

| Material Cost | Filler metals can be expensive | Filler materials generally cheaper |

| Finishing Cost | Minimal to none (clean joints) | High (grinding, straightening needed) |

| Best For | High-volume, dissimilar metals, thin sections | Maximum strength, high-temperature applications |

Need help choosing the right metal joining process for your lab or production line? At KINTEK, we specialize in providing lab equipment and consumables that streamline your workflow and reduce costs. Whether you're brazing or welding, our solutions ensure precision and efficiency. Contact our experts today to optimize your joining process and achieve superior results!

Visual Guide

Related Products

- Vacuum Heat Treat Sintering Brazing Furnace

- 1700℃ Controlled Atmosphere Furnace Nitrogen Inert Atmosphere Furnace

- 1200℃ Controlled Atmosphere Furnace Nitrogen Inert Atmosphere Furnace

- 1400℃ Controlled Atmosphere Furnace with Nitrogen and Inert Atmosphere

- Controlled Nitrogen Inert Hydrogen Atmosphere Furnace

People Also Ask

- What is the cost of a vacuum brazing furnace? A guide to key factors and investment strategy

- Which element made stainless steel difficult to brazed? It's Chromium's Oxide Layer

- What are the advantages of brazing compared to welding? Achieve Clean, Low-Distortion Metal Joining

- Does brazing require heat? Yes, it's the catalyst for creating strong, permanent bonds.

- What is vacuum brazed? The Ultimate Guide to High-Purity Metal Joining