In short, no. Diamond-Like Carbon (DLC) coating is not scratch-proof, but it is exceptionally scratch-resistant. The term "proof" implies total invincibility, a quality that does not exist in material science. However, DLC offers one of the highest levels of scratch resistance available for everyday items like watches, knives, and tools, far surpassing uncoated steel or other common coatings like PVD.

The durability of a DLC coating is not just about its own hardness, but is also critically dependent on the hardness of the material underneath it. A hard coating on a soft base can still be damaged by an impact that deforms the substrate, much like a thin layer of ice will crack if the mud beneath it gives way.

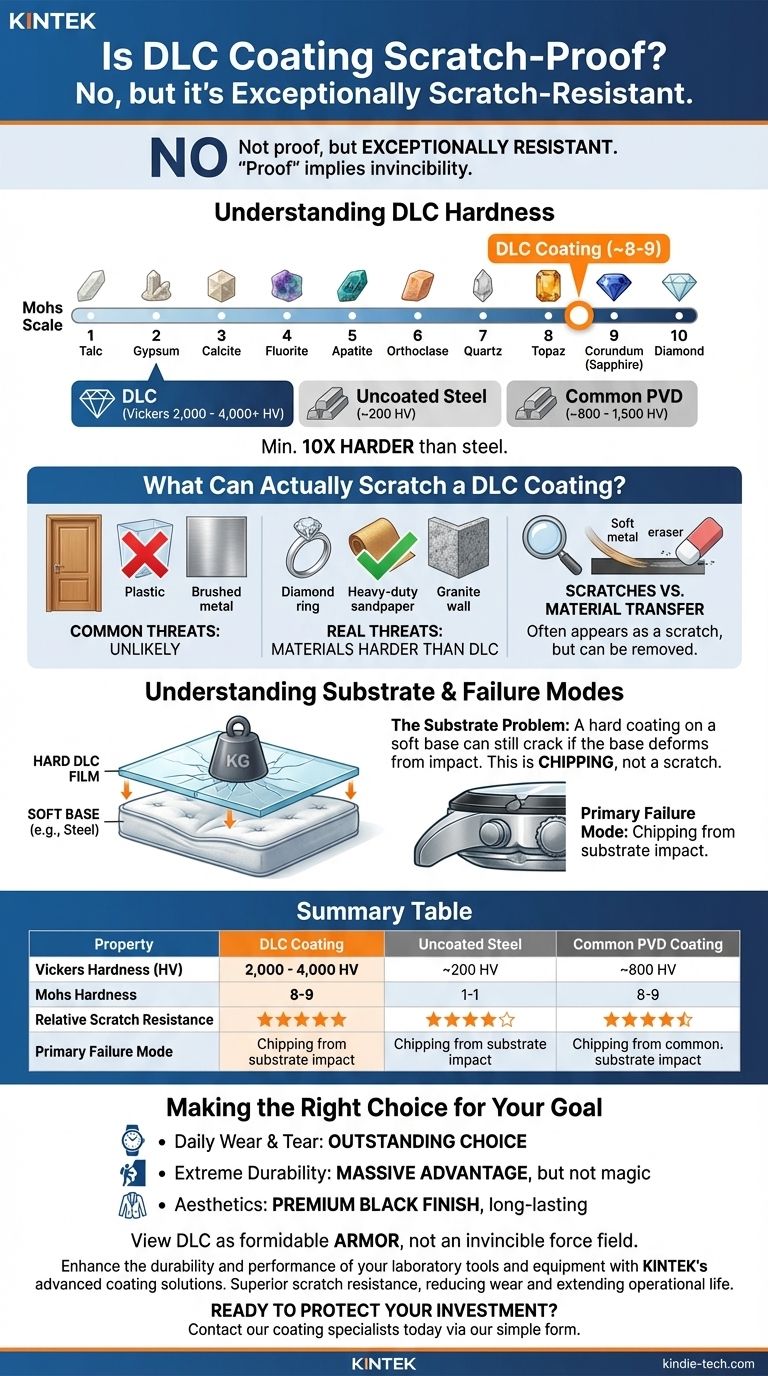

Understanding DLC Hardness

A Thin Film of Diamond-Like Carbon

It is crucial to understand that DLC is not a solid material but an extremely thin, hard film applied to the surface of a base material (the substrate), typically stainless steel or titanium. This film is usually only 2 to 5 microns thick—much thinner than a human hair.

Its purpose is to act as a protective shell, lending its extreme surface hardness to the object.

Quantifying the Resistance

The hardness of DLC is immense. On the Vickers hardness scale, it can range from 2000 to over 4000 HV. For comparison, 316L stainless steel is around 200 HV, and titanium is about 350 HV. This means DLC is, at a minimum, 10 times harder than the steel it typically coats.

On the Mohs scale of mineral hardness, DLC lands around an 8 or 9. This places it in the same league as sapphire crystal, one of the hardest materials used in consumer goods.

What Can Actually Scratch a DLC Coating?

The Hardness Hierarchy

The fundamental rule of materials is simple: a harder object will scratch a softer one. Since DLC is around a 9 on the Mohs scale, only materials of equal or greater hardness can reliably scratch it.

Common Real-World Threats

The most common materials harder than DLC are rare. You won't scratch it on a wooden door frame, a piece of plastic, or by brushing against most metals.

However, scratches are still possible. The primary culprits are materials containing minerals like silicon carbide (Mohs 9), moissanite (Mohs 9.5), or diamond (Mohs 10). You might find these in:

- A diamond ring or other diamond jewelry.

- Some heavy-duty sandpapers or nail files.

- Accidentally scraping against a granite or masonry wall, which can contain extremely hard mineral aggregates like quartz (Mohs 7) or harder inclusions.

Scratches vs. Material Transfer

Often, what appears to be a scratch is actually material transfer. If you scrape your DLC-coated watch against a softer aluminum door frame, some of the aluminum may rub off onto the hard DLC surface. This looks like a silver scratch but can often be removed with a pencil eraser or vigorous cleaning, revealing the undamaged coating beneath.

Understanding the Trade-offs and Failure Modes

The Substrate Problem

The single most important factor in DLC's real-world durability is the hardness of the material it is bonded to.

Applying DLC to a relatively soft material like 316L stainless steel is like laying a sheet of glass on a mattress. The glass is hard, but if you press down hard enough, the mattress will give way, and the glass will crack.

Similarly, a sharp impact on a DLC-coated watch can dent the softer steel underneath. This deformation of the substrate will cause the hard, brittle DLC film to crack, chip, or flake off at the point of impact. This is not a "scratch," but it is the most common form of visible damage.

Coating Adhesion and Thickness

The performance of DLC also depends on how well it was applied. A poor bond between the coating and the substrate can lead to peeling or flaking, even without a major impact.

While a thicker coating can offer slightly more abrasive resistance, it can also be more prone to chipping on impact because it is less flexible. There is a balance that expert applicators must strike.

Making the Right Choice for Your Goal

When considering a DLC-coated product, it's essential to align your expectations with its real-world capabilities.

- If your primary focus is daily wear and tear: DLC is an outstanding choice. It will effectively eliminate the minor scuffs, scrapes, and swirl marks that accumulate on uncoated steel or titanium from contact with desks, zippers, and other common objects.

- If your primary focus is extreme durability: DLC provides a massive advantage, but it is not a "magic shield." A significant impact against a hard surface like rock or concrete can still cause the underlying metal to dent, leading to a chip in the coating.

- If your primary focus is aesthetics: DLC provides a durable, premium black finish that is vastly superior to paint or basic PVD coatings. It will maintain its look far longer under normal use.

Ultimately, view DLC as a formidable layer of armor that dramatically reduces the risk of everyday damage, not as an invincible force field.

Summary Table:

| Property | DLC Coating | Uncoated Steel | Common PVD Coating |

|---|---|---|---|

| Vickers Hardness (HV) | 2,000 - 4,000+ | ~200 | 800 - 1,500 |

| Mohs Hardness | ~8 - 9 | ~4 - 4.5 | ~6 - 7 |

| Relative Scratch Resistance | Very High | Low | Medium |

| Primary Failure Mode | Chipping from substrate impact | Scratches & scuffs | Wear & abrasion |

Enhance the durability and performance of your laboratory tools and equipment with KINTEK's advanced coating solutions.

Our expertise in lab equipment and consumables means we understand the rigorous demands of your work. A DLC coating from KINTEK can provide your instruments, blades, and components with superior scratch resistance, reducing wear and extending their operational life. This ensures more reliable results and lower long-term costs.

Ready to protect your investment? Contact our coating specialists today via our simple form to discuss how a DLC coating can be tailored to your specific laboratory needs.

Visual Guide

Related Products

- Custom CVD Diamond Coating for Lab Applications

- CVD Diamond Cutting Tool Blanks for Precision Machining

- RF PECVD System Radio Frequency Plasma-Enhanced Chemical Vapor Deposition RF PECVD

- Hydrophilic Carbon Paper TGPH060 for Battery Lab Applications

- High-Purity Titanium Foil and Sheet for Industrial Applications

People Also Ask

- What are the process advantages of utilizing PECVD to produce graphene nanowalls from natural essential oils?

- What are the advantages of PECVD? Enable Low-Temperature, High-Quality Thin-Film Deposition

- What is the pressure for PECVD? Mastering the Key Parameter for Thin Film Quality

- What is the temperature of plasma CVD? Unlock Low-Temp Coating for Sensitive Materials

- What is plasma in PECVD? The Key to Low-Temperature, High-Quality Thin-Film Deposition

- What is typical process pressure for PECVD? Optimize Your Thin-Film Deposition Process

- What is the application of plasma enhanced CVD? Enable Low-Temperature Thin Film Deposition

- How strong is DLC coating? Discover the Ultimate Shield for Wear and Friction