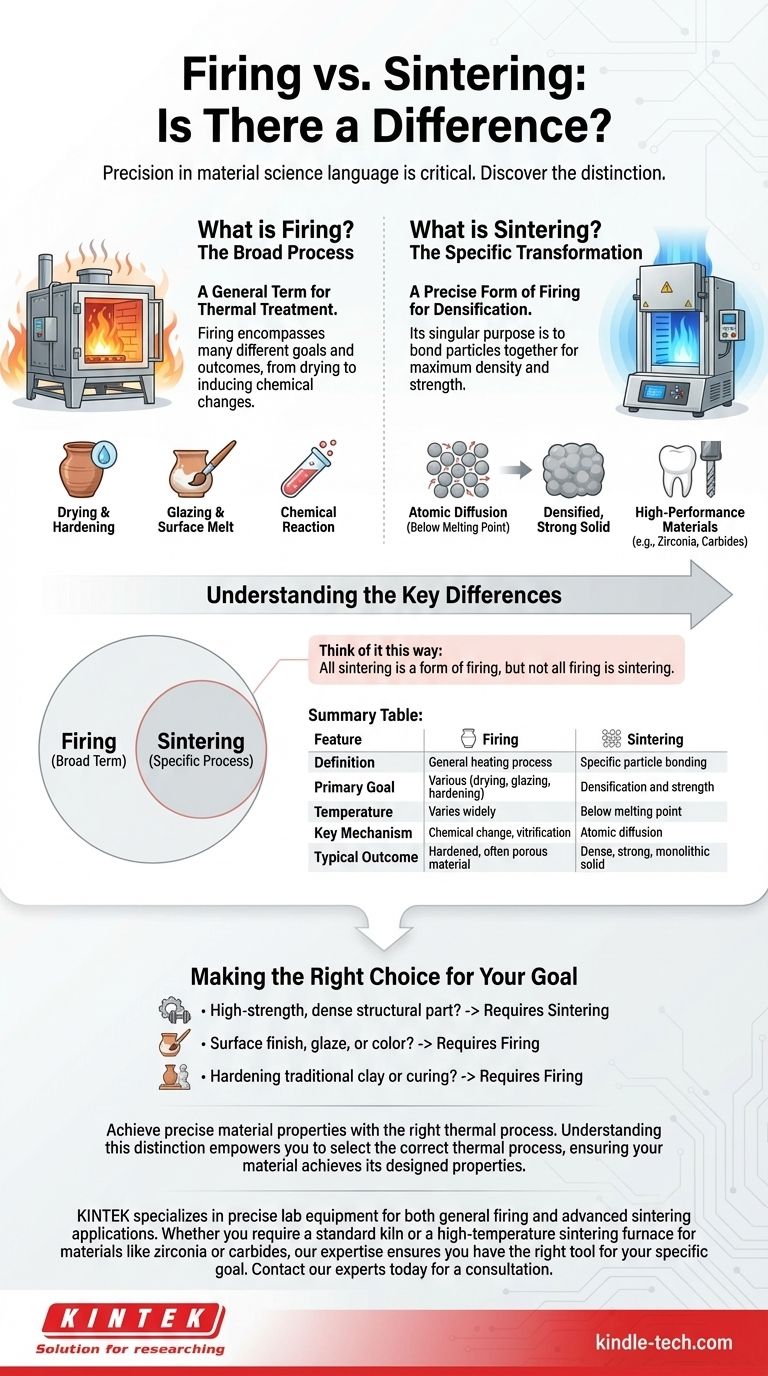

In material science, precision in language is critical. While the terms are often used interchangeably in casual conversation, firing and sintering are not the same. Sintering is a very specific, high-temperature thermal process that falls under the broader category of firing. Think of it this way: all sintering is a form of firing, but not all firing is sintering.

Firing is the general term for heating a material in a furnace to induce a physical or chemical change. Sintering is a specific type of firing where powdered material is heated to just below its melting point, causing the particles to bond together and form a dense, solid mass.

What is Firing? The Broad Process

Firing is a foundational technique in material processing, used for millennia to transform materials with heat. It is a broad category encompassing many different goals and outcomes.

A General Term for Thermal Treatment

The term firing simply refers to the controlled heating of an object in a kiln or furnace. The specific temperature, duration, and atmospheric conditions of the firing cycle are all tailored to achieve a desired result.

The Goals of Firing

A material may be fired for many reasons. This can include simply drying out residual moisture, hardening a clay body, melting a surface glaze, or initiating a chemical reaction. For example, "infiltration firing," as mentioned for some ceramics, is used to introduce a secondary material (like glass) into a porous structure.

What is Sintering? The Specific Transformation

Sintering is a highly technical and precise form of firing. Its purpose is not just to heat the material, but to fundamentally change its microstructure to achieve maximum density and strength.

The Core Mechanism: Atomic Diffusion

Sintering works by heating a compacted powder to a temperature high enough to excite its atoms, but below its melting point. At this critical temperature, atoms begin to migrate across the boundaries of individual particles, a process called atomic diffusion. This diffusion fuses the particles together, eliminating the voids between them.

The Primary Goal: Densification and Strength

The single most important goal of sintering is densification. By eliminating porosity, sintering dramatically increases the material's density, mechanical strength, and toughness. This is why it is the required process for high-performance structural materials like zirconia dental crowns, carbide cutting tools, and aerospace components.

The Critical Role of Equipment

Because sintering relies on precise atomic-level changes, it requires extremely accurate control over temperature and often the furnace atmosphere. This is why specialized, high-temperature sintering furnaces are necessary for materials like zirconia, while other firing processes can be done in more general-purpose porcelain furnaces or kilns.

Understanding the Trade-offs and Key Differences

Confusing these terms can lead to significant processing errors, damaged equipment, and failed components. The distinction is not academic; it is a practical necessity.

Purpose: General Change vs. Specific Bonding

The purpose of firing is broad—it can be anything from drying to glazing. The purpose of sintering is singular and specific: to bond particles together to create a dense, non-porous solid.

Temperature: A Key Distinguisher

While all sintering is a high-temperature process relative to the material's properties, the key is that it occurs below the melting point. Other firing processes might involve much lower temperatures (for drying) or higher temperatures that cause partial or full melting (for glazes).

Outcome: Hardening vs. Microstructural Unification

A fired clay pot is hard, but it remains porous. A sintered zirconia part is not just hard; it has become a nearly monolithic piece with vastly superior strength because the original particles are no longer distinct entities.

Making the Right Choice for Your Goal

Selecting the correct thermal process is determined entirely by the final properties your material needs to possess.

- If your primary focus is creating a high-strength, dense structural part: You must perform sintering and will require a furnace capable of reaching and holding the precise temperatures needed for atomic diffusion.

- If your primary focus is applying a surface finish, glaze, or color: You are performing a type of firing that does not require densification, and a standard kiln or furnace is likely sufficient.

- If your primary focus is hardening a traditional clay body or curing a binder: You are performing firing, where the goal is chemical change and vitrification, not particle fusion through diffusion.

Understanding this distinction empowers you to select the correct thermal process, ensuring your material achieves its designed properties.

Summary Table:

| Feature | Firing | Sintering |

|---|---|---|

| Definition | General term for heating materials | Specific process of particle bonding |

| Primary Goal | Various (drying, hardening, glazing) | Densification and strength |

| Temperature | Varies widely | Below the material's melting point |

| Key Mechanism | Chemical change, vitrification | Atomic diffusion |

| Typical Outcome | Hardened, often porous material | Dense, strong, monolithic solid |

Achieve precise material properties with the right thermal process.

Understanding the distinction between firing and sintering is essential for producing high-performance components. The choice directly impacts the strength, density, and final quality of your materials.

KINTEK specializes in providing the precise lab equipment you need for both general firing and advanced sintering applications. Whether you require a standard kiln or a high-temperature sintering furnace for materials like zirconia or carbides, our expertise ensures you have the right tool for your specific goal.

Let us help you select the perfect furnace to achieve your material's designed properties. Contact our experts today for a consultation.

Visual Guide

Related Products

- 1800℃ Muffle Oven Furnace for Laboratory

- 1700℃ Muffle Oven Furnace for Laboratory

- Laboratory Muffle Oven Furnace Bottom Lifting Muffle Furnace

- 1400℃ Muffle Oven Furnace for Laboratory

- High Temperature Muffle Oven Furnace for Laboratory Debinding and Pre Sintering

People Also Ask

- Why is the metal melting temperature important? The Key to Manufacturing & Performance

- What temperature does molten steel melt? Understand the Melting Range, Not a Single Point

- What is the primary function of a muffle furnace in assessing NbTiVZr alloys? Test High-Temp Nuclear Durability

- What happens in the muffle furnace? Achieve Pure, Uniform High-Temperature Processing

- Is the sintering process hazardous? Identifying Key Risks and Safety Protocols