Yes, graphite is an exceptional material for high-temperature applications, but its performance is critically dependent on the surrounding atmosphere. In inert or vacuum environments, it retains its structural integrity at temperatures far exceeding the melting point of most metals. However, in the presence of oxygen, its capabilities are severely limited.

The core takeaway is that graphite's value at extreme temperatures comes from a unique combination of properties: it gets stronger as it gets hotter and has outstanding resistance to thermal shock. Its primary limitation, however, is its vulnerability to oxidation, making the operating atmosphere the single most important factor for its successful use.

Why Graphite Excels at Extreme Temperatures

Graphite's behavior at high temperatures is often counter-intuitive. Unlike metals that soften and weaken when heated, graphite's performance improves, making it a premier material for the most demanding thermal environments.

Increasing Strength with Heat

Graphite exhibits a rare and highly valuable property: its tensile strength increases with temperature, peaking at around 2500°C (4532°F). At this point, it can be twice as strong as it is at room temperature.

This allows it to maintain structural integrity under loads that would cause refractory metals to fail.

Exceptional Thermal Shock Resistance

The material has very high thermal conductivity combined with low thermal expansion. This combination is the key to its excellent resistance to thermal shock.

It can be heated and cooled very rapidly without cracking or failing. As the reference material notes, this property is invaluable in industrial processes as it significantly reduces process cycle times.

A Sublimation Point Beyond Most Metals

Graphite does not melt at atmospheric pressure. Instead, it sublimates—turning directly from a solid to a gas—at an extremely high temperature, around 3650°C (6602°F).

This gives it a usable temperature range far beyond even high-performance metals like tungsten or molybdenum.

The Critical Factor: Atmosphere and Oxidation

The single greatest weakness of graphite at high temperatures is its reaction with oxygen. This is not a minor detail; it is the central trade-off that dictates its use.

The Oxygen Problem

In an oxygen-rich atmosphere like open air, graphite begins to oxidize (effectively, burn) at temperatures as low as 500°C (932°F).

This reaction forms CO or CO2 gas, causing the material to lose mass, degrade, and ultimately fail. This makes unprotected graphite unsuitable for high-temperature use in air.

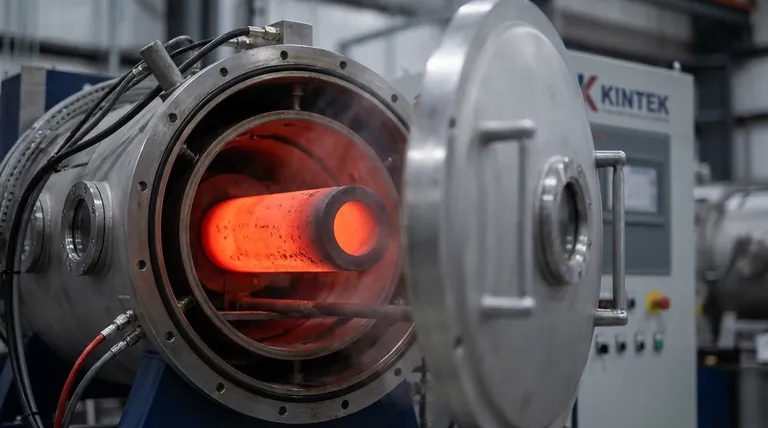

Thriving in Inert Environments

To unlock graphite's full potential, it must be used in a vacuum or an inert gas atmosphere, such as argon or nitrogen.

In these controlled environments, oxidation is prevented, and graphite can be safely used up to temperatures approaching 3000°C. This is why it is the dominant material for vacuum furnace components.

Protective Coatings and Material Grades

For applications with some oxygen exposure, special anti-oxidation coatings (like silicon carbide) can be applied to seal the graphite's surface.

Furthermore, it is important to select the correct grade of graphite. High-density, high-purity isotropic or extruded grades are engineered specifically for high-temperature structural performance.

Making the Right Choice for Your Application

The decision to use graphite hinges entirely on your specific operating conditions.

- If your primary focus is an open-air environment above 500°C: Standard graphite is unsuitable. You must consider either a specialized protective coating or a different material, like a ceramic or refractory metal.

- If your primary focus is a vacuum or inert gas furnace: Graphite is one of the best and most cost-effective materials available, offering superior strength and stability at extreme temperatures.

- If your primary focus is rapid thermal cycling: Graphite's elite thermal shock resistance makes it an ideal candidate, capable of reducing cycle times and increasing the lifespan of your equipment.

Understanding the interplay between graphite's immense thermal strength and its environmental vulnerabilities is the key to leveraging it effectively.

Summary Table:

| Property | Behavior at High Temperature | Key Benefit |

|---|---|---|

| Strength | Increases up to ~2500°C | Maintains integrity under extreme loads |

| Thermal Shock Resistance | Excellent due to high conductivity & low expansion | Enables rapid heating/cooling without cracking |

| Melting Point | Sublimates at ~3650°C | Usable range far exceeds most metals |

| Oxidation Resistance | Poor in air above 500°C; Excellent in inert/vacuum | Atmosphere is the critical factor for success |

Ready to leverage graphite's high-temperature capabilities in your lab?

KINTEK specializes in high-performance lab equipment and consumables, including graphite components designed for vacuum and inert atmosphere furnaces. Our expertise ensures you get the right material grade and configuration for superior thermal stability, rapid cycling, and long-lasting performance.

Contact our experts today to discuss how our graphite solutions can enhance your high-temperature processes!

Visual Guide

Related Products

- Graphite Vacuum Continuous Graphitization Furnace

- Vertical High Temperature Graphite Vacuum Graphitization Furnace

- Ultra-High Temperature Graphite Vacuum Graphitization Furnace

- Graphite Vacuum Furnace IGBT Experimental Graphitization Furnace

- Laboratory Muffle Oven Furnace Bottom Lifting Muffle Furnace

People Also Ask

- Can graphite withstand high-temperature? Maximizing Performance in Controlled Atmospheres

- How is synthetic graphite manufactured? A Deep Dive into the High-Temperature Process

- What are the mechanical properties of graphite? Harnessing Rigidity and Managing Brittleness

- What happens to graphite at high temperatures? Unlock its Extreme Heat Resistance

- What is the thermal coefficient of graphite? Unlock Its Unique Thermal Stability