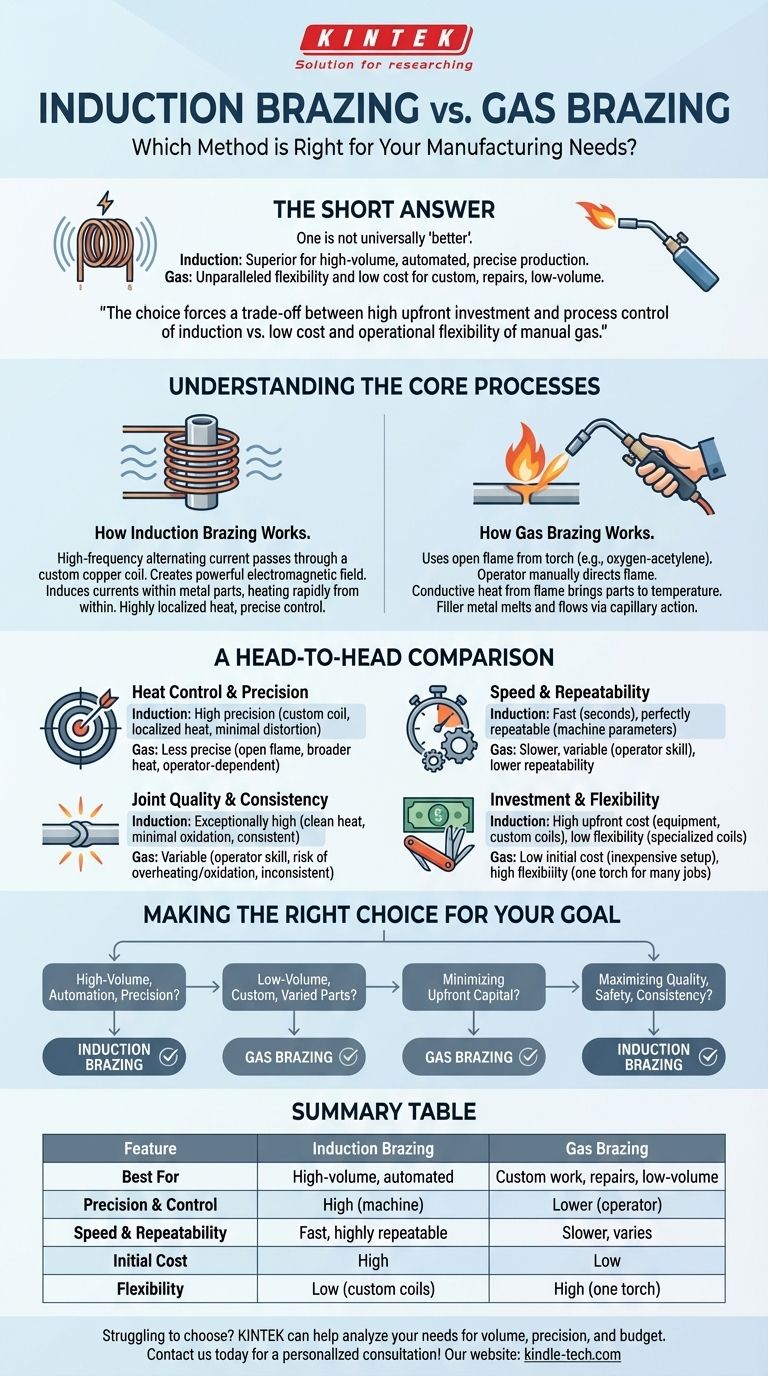

The short answer is: one is not universally "better" than the other. Induction brazing is superior for high-volume, automated production where precision and repeatability are critical. Gas brazing, by contrast, offers unparalleled flexibility and lower initial costs, making it ideal for custom work, repairs, and low-volume applications.

The choice between induction and gas brazing is a fundamental manufacturing decision. It forces a trade-off between the high upfront investment and process control of induction versus the low cost and operational flexibility of manual gas torch methods.

Understanding the Core Processes

To compare these methods, you first need to understand how each applies heat. The mechanism of heat delivery is the primary source of all their respective strengths and weaknesses.

How Induction Brazing Works

Induction brazing uses a high-frequency alternating current passed through a precisely shaped copper coil. This creates a powerful electromagnetic field around the part to be brazed.

This field induces electrical currents within the metal parts, causing them to heat up rapidly from within. The heat is highly localized to the area defined by the coil, allowing the filler metal to flow into the joint without overheating the surrounding material.

How Gas Brazing Works

Gas brazing is a more traditional method that uses an open flame from a torch, typically fueled by an oxygen-acetylene or propane mixture.

An operator manually directs this flame onto the base materials surrounding the joint. The conductive heat transfer from the flame brings the parts up to the brazing temperature, at which point the filler metal is introduced and melts, flowing into the joint via capillary action.

A Head-to-Head Comparison

Each method excels in different areas. The right choice depends entirely on your operational priorities.

Heat Control & Precision

Induction heating is incredibly precise. The custom-designed coil ensures that only the intended area is heated, protecting heat-sensitive components nearby and minimizing part distortion.

Gas brazing is far less precise. The open flame heats a much broader area, which can be a significant drawback when working with complex assemblies or delicate parts. Control is entirely dependent on operator skill.

Speed & Repeatability

For production environments, induction is significantly faster, often completing a heating cycle in seconds. Because the process is controlled by machine parameters (power and time), it is perfectly repeatable, ensuring every joint is identical.

Gas brazing is a slower, manual process. The time required for each joint can vary significantly from one operator to another, making it difficult to achieve high levels of repeatability.

Joint Quality & Consistency

The clean, controlled heat of induction results in exceptionally high-quality joints. It produces minimal oxidation and allows for a clean, strong bond with less filler metal. This consistency reduces scrap and rework rates.

The quality of a gas-brazed joint is a direct reflection of the operator's skill. An experienced technician can produce excellent results, but there is always a higher risk of overheating, excessive oxidation, and inconsistent filler flow.

Understanding the Trade-offs

The superiority of induction on technical grounds is offset by critical factors of cost and flexibility.

Initial Investment

The primary barrier to induction brazing is high upfront cost. The power supply, workstation, and, most importantly, the custom-designed coils for each specific joint geometry represent a significant capital investment.

Gas brazing equipment is extremely inexpensive. A complete torch setup can be acquired for a very small fraction of the cost of an induction system, making it accessible to virtually any operation.

Operational Flexibility

Induction systems are highly specialized. A coil designed for one part will not work for another, making it inefficient for high-mix, low-volume production or one-off repairs. Changing over from one part to another requires changing the coil.

A gas torch is the definition of flexibility. A single torch can be used to braze an almost infinite variety of part shapes and sizes without any setup changes, making it perfect for repair shops and custom fabrication.

Making the Right Choice for Your Goal

Select the process that aligns directly with your manufacturing objectives and constraints.

- If your primary focus is high-volume production and automation: Induction brazing is the clear choice for its speed, repeatability, and superior quality control.

- If your primary focus is low-volume work, custom repairs, or varied part geometries: Gas brazing provides the necessary flexibility at a fraction of the cost.

- If your primary focus is minimizing upfront capital investment: Gas brazing is the only viable option due to its exceptionally low equipment cost.

- If your primary focus is maximizing joint quality, process safety, and consistency: Induction brazing delivers unmatched control and a cleaner working environment.

Ultimately, choosing the right brazing method is about selecting the correct tool for the specific job at hand.

Summary Table:

| Feature | Induction Brazing | Gas Brazing |

|---|---|---|

| Best For | High-volume, automated production | Custom work, repairs, low-volume |

| Precision & Control | High (machine-controlled) | Lower (operator-dependent) |

| Speed & Repeatability | Fast and highly repeatable | Slower, varies by operator |

| Initial Cost | High | Low |

| Flexibility | Low (requires custom coils) | High (one torch for many jobs) |

Struggling to choose the right brazing method for your lab or production line? KINTEK specializes in lab equipment and consumables, serving laboratory needs. Our experts can help you analyze your specific requirements for volume, precision, and budget to recommend the optimal solution. Let us help you achieve stronger, more consistent joints and improve your manufacturing efficiency. Contact our team today for a personalized consultation!

Visual Guide

Related Products

- Non Consumable Vacuum Arc Induction Melting Furnace

- Manual Cold Isostatic Pressing Machine CIP Pellet Press

- Powerful Plastic Crusher Machine

- Three-dimensional electromagnetic sieving instrument

- Metal Disc Electrode Electrochemical Electrode

People Also Ask

- What are the advantages and disadvantages of brazing? A Guide to Strong, Clean Metal Joining

- What are the different types of melting process? From Smelting to Suspension for Ultimate Purity

- What are the strengths of brazing? Achieve Strong, Clean, and Precise Metal Joining

- How does vacuum arc melting equipment facilitate Ti-Cr-Al-Nb alloy prep? Precision High-Temp Melting Explained

- What is AC frame? Decoding the Two Meanings in Wi-Fi and Video