Yes, induction heating is exceptionally efficient. With a properly designed system, the efficiency of converting electrical energy into heat within the workpiece can exceed 90%. This high level of performance is achieved because heat is generated directly inside the material itself, dramatically reducing the energy waste common in traditional heating methods.

Induction's true value isn't just its high electrical efficiency, but its process efficiency. By generating heat precisely and instantly within the part, it minimizes wasted energy, reduces process time, and eliminates contamination, solving problems that conventional heating methods cannot.

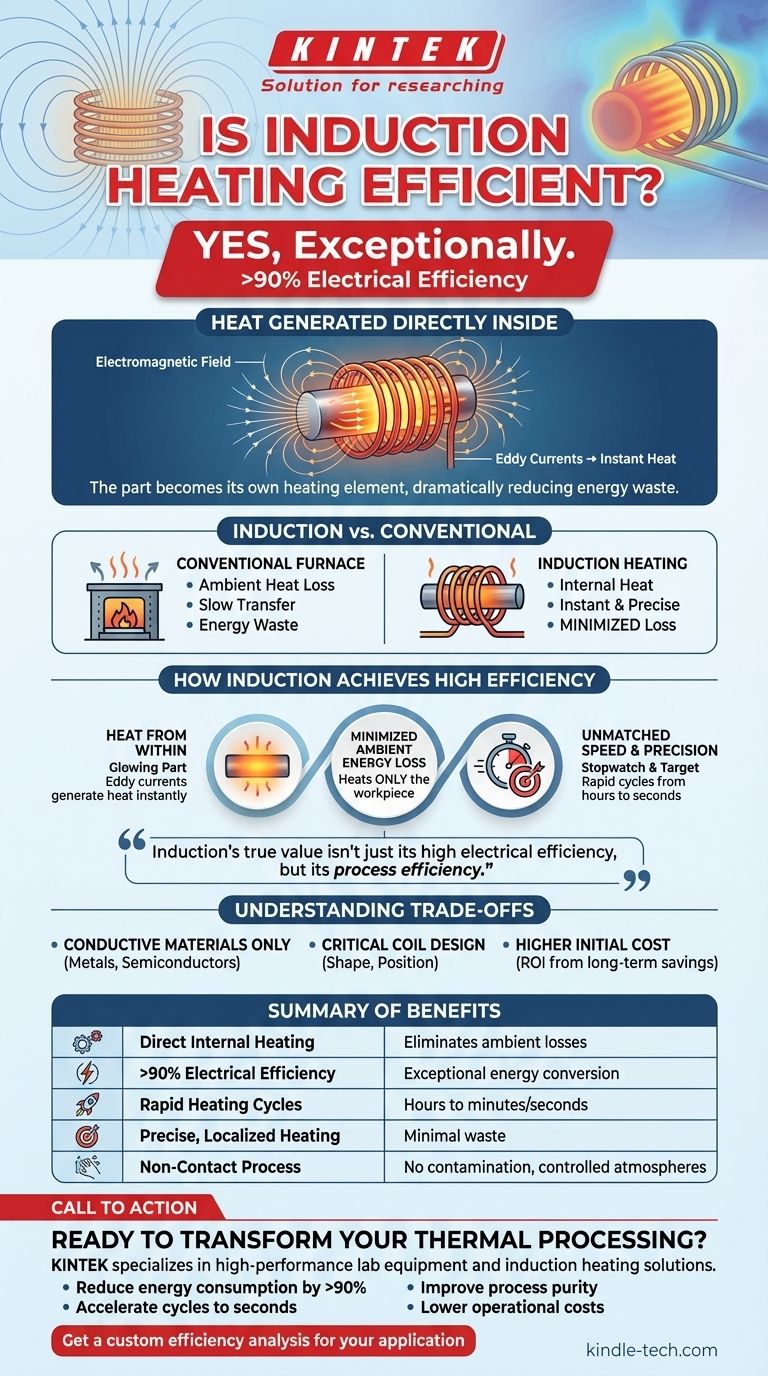

How Induction Achieves High Efficiency

The efficiency of induction heating is not a single feature but the result of its fundamental operating principle. Unlike a furnace that heats the air and a chamber to slowly warm a part through conduction, induction works instantly and internally.

Heat from Within the Material

The core of induction is an alternating electromagnetic field. When a conductive material is placed inside this field, it induces electrical currents (known as eddy currents) directly within the part. The material's natural resistance to these currents generates immediate, localized heat.

Essentially, the part becomes its own heating element. This process bypasses the slow and wasteful step of transferring heat from an external source.

Minimized Ambient Energy Loss

Conventional furnaces lose a significant amount of energy heating the furnace walls, the surrounding air, and the fixtures holding the parts. This is known as ambient heat loss.

Because induction heats only the workpiece, this peripheral energy waste is almost entirely eliminated. The heat is generated only where it is needed, for only as long as it is needed.

Unmatched Speed and Precision

The ability to generate heat instantly allows for incredibly rapid heating cycles. A process that might take hours in a furnace can often be completed in minutes or even seconds with induction.

This speed is a form of efficiency. Shorter cycle times mean less overall energy consumed per part, leading to higher throughput and lower operational costs.

Understanding the Trade-offs and Requirements

While highly efficient, induction heating is not a universal solution. Its effectiveness is dependent on specific conditions and proper engineering.

Material Dependency

Induction only works on materials that are electrically conductive, such as metals like steel, copper, and aluminum, or semiconductors like graphite and silicon. It cannot be used to directly heat non-conductive materials like most ceramics or plastics.

The Critical Role of Coil Design

The efficiency of the system is heavily dependent on the design of the induction coil and the power supply. The coil must be shaped and positioned correctly relative to the workpiece to create an optimal electromagnetic field.

A poorly designed or mismatched coil will result in inefficient power transfer, negating many of the technology's core benefits.

Initial System Cost

The initial capital investment for an induction heating system can be higher than that for a simple conventional furnace. The return on investment comes from lower long-term energy costs, increased production speed, improved quality, and reduced scrap.

Making the Right Choice for Your Application

Choosing induction heating depends entirely on your primary process goals.

- If your primary focus is process purity and control: Induction is ideal, as the non-contact heating prevents contamination and allows for work in controlled atmospheres or vacuums.

- If your primary focus is speed and high-volume throughput: The rapid, repeatable heating cycles of induction can dramatically shorten production times compared to batch furnace operations.

- If your primary focus is long-term energy savings: Induction's high efficiency directly translates to lower energy consumption per part, reducing operational expenses over the life of the equipment.

Ultimately, induction heating provides a level of speed, precision, and efficiency that is simply unattainable with conventional heating technologies.

Summary Table:

| Feature | Benefit |

|---|---|

| Direct Internal Heating | Heat generated inside the workpiece, eliminating ambient losses |

| >90% Electrical Efficiency | Exceptional energy conversion from electricity to heat |

| Rapid Heating Cycles | Process times reduced from hours to minutes/seconds |

| Precise, Localized Heating | Targeted energy application with minimal waste |

| Non-Contact Process | No contamination, suitable for controlled atmospheres |

Ready to transform your thermal processing with induction heating efficiency?

At KINTEK, we specialize in high-performance lab equipment and thermal solutions for laboratories and industrial applications. Our induction heating systems deliver the precise, efficient, and contamination-free heating your processes demand.

Contact us today to discuss how our induction heating solutions can:

- Reduce your energy consumption by over 90%

- Accelerate your heating cycles from hours to seconds

- Improve process purity and repeatability

- Lower your long-term operational costs

Get a custom efficiency analysis for your application

Visual Guide

Related Products

- Silicon Carbide SiC Thermal Heating Elements for Electric Furnace

- HFCVD Machine System Equipment for Drawing Die Nano-Diamond Coating

- Anti-Cracking Press Mold for Lab Use

- Engineering Advanced Fine Ceramics Aluminum Oxide Al2O3 Heat Sink for Insulation

- Laboratory Test Sieves and Sieving Machines

People Also Ask

- What are silicon carbide heating elements used for? Reliable High-Temp Heating for Industrial Processes

- What is SiC elements? The Ultimate High-Temperature Heating Solution

- What is a silicon carbide heating element? Unlock Extreme Heat for Industrial Processes

- What kind of metal is used in heating elements? A Guide to Materials for Every Temperature & Atmosphere

- What are the uses of silicon carbide rod? The Ultimate Heating Solution for Extreme Temperatures