No, induction welding is not the same as brazing. They are fundamentally different metal joining processes. Induction welding uses electromagnetic heating to melt the base metals themselves to fuse them together, while brazing uses a separate filler metal to join parts without melting the base materials.

The core confusion arises because induction is a heating method, not a joining process. This single method of heating can be used to perform two distinct processes: welding (melting the base metals) or brazing (melting only a filler metal).

The Core Difference: Melting the Base Metal

The defining distinction between any welding process and brazing is whether the parent materials being joined are melted.

What is Welding?

Welding creates a direct metallurgical bond by melting the edges of the base materials, causing them to flow together. A filler material may be added to the molten pool to add strength.

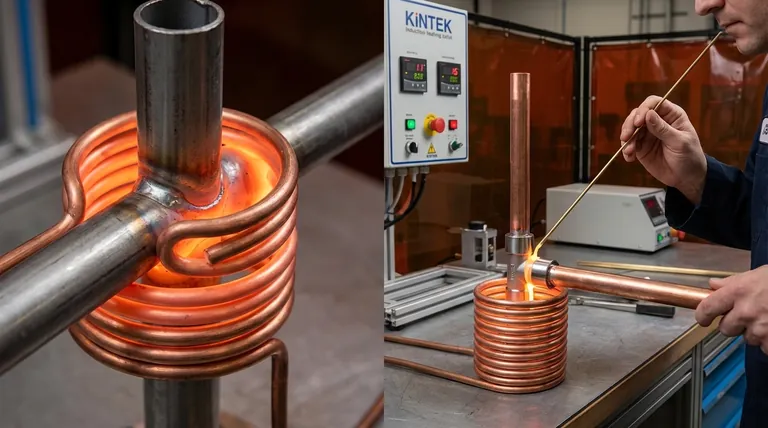

When this is done using electromagnetic currents to generate heat, it is called induction welding. The result is a single, continuous piece of metal where the joint is often as strong as the original materials.

What is Brazing?

Brazing is more like high-temperature soldering. It joins two components by melting a filler metal with a lower melting point than the base materials.

This molten filler is drawn into the tight-fitting gap between the parts via capillary action and solidifies, creating a strong bond. The base materials get very hot, but they never melt. When induction is the heat source, this is called induction brazing.

Where Induction Fits In

Induction heating is simply a tool for generating rapid, precise, and localized heat. It is a highly efficient method used in many industrial processes.

Because it offers excellent control, it can be precisely tuned to either heat metals to their melting point for welding or heat them to a lower temperature just sufficient to melt a brazing alloy.

Why Choose One Over the Other?

The choice between induction welding and induction brazing depends entirely on the materials being joined and the desired outcome for the final assembly.

The Strength of a Welded Joint

Because welding fuses the base materials, it creates a homogenous joint. This is ideal when maximum strength is the primary requirement and you are joining similar or identical metals.

The Versatility of a Brazed Joint

Brazing is exceptionally effective for joining dissimilar metals, such as copper to steel, which can be difficult or impossible to weld. Since the base metals don't melt, there is less risk of thermal distortion, making it suitable for delicate or complex assemblies.

The Advantage of Induction Heating

Regardless of the process, using induction as the heat source provides significant benefits. It is fast, clean, easily automated, and delivers highly repeatable results with minimal energy waste.

Understanding the Trade-offs

Each process has inherent limitations that make it suitable for different applications.

Welding: Risk of Distortion and Stress

The intense, localized heat required to melt base metals can cause them to warp or introduce internal stresses. This is a significant concern for precision assemblies or thin materials.

Brazing: Joint Strength is Limited

While a properly brazed joint is very strong, its ultimate strength is determined by the filler material used. The joint will typically not be as strong as the parent materials themselves, unlike a good weld.

Material Compatibility Is Key

Welding is generally restricted to joining similar metals. Brazing, however, excels at joining a wide variety of dissimilar materials because it avoids the metallurgical incompatibilities that can arise when trying to fuse different alloys.

Making the Right Choice for Your Goal

Selecting the correct process requires understanding your primary objective for the joint.

- If your primary focus is creating a single, monolithic part with maximum strength: Welding is the correct process, and induction is an excellent way to apply the heat.

- If your primary focus is joining dissimilar metals or heat-sensitive components with minimal distortion: Brazing is the superior choice, and induction provides precise temperature control.

- If your primary focus is speed, automation, and repeatable quality: Using induction heating for either welding or brazing is a highly effective manufacturing strategy.

Ultimately, understanding that welding fuses base metals while brazing joins them with a filler is the key to choosing the right process for your application.

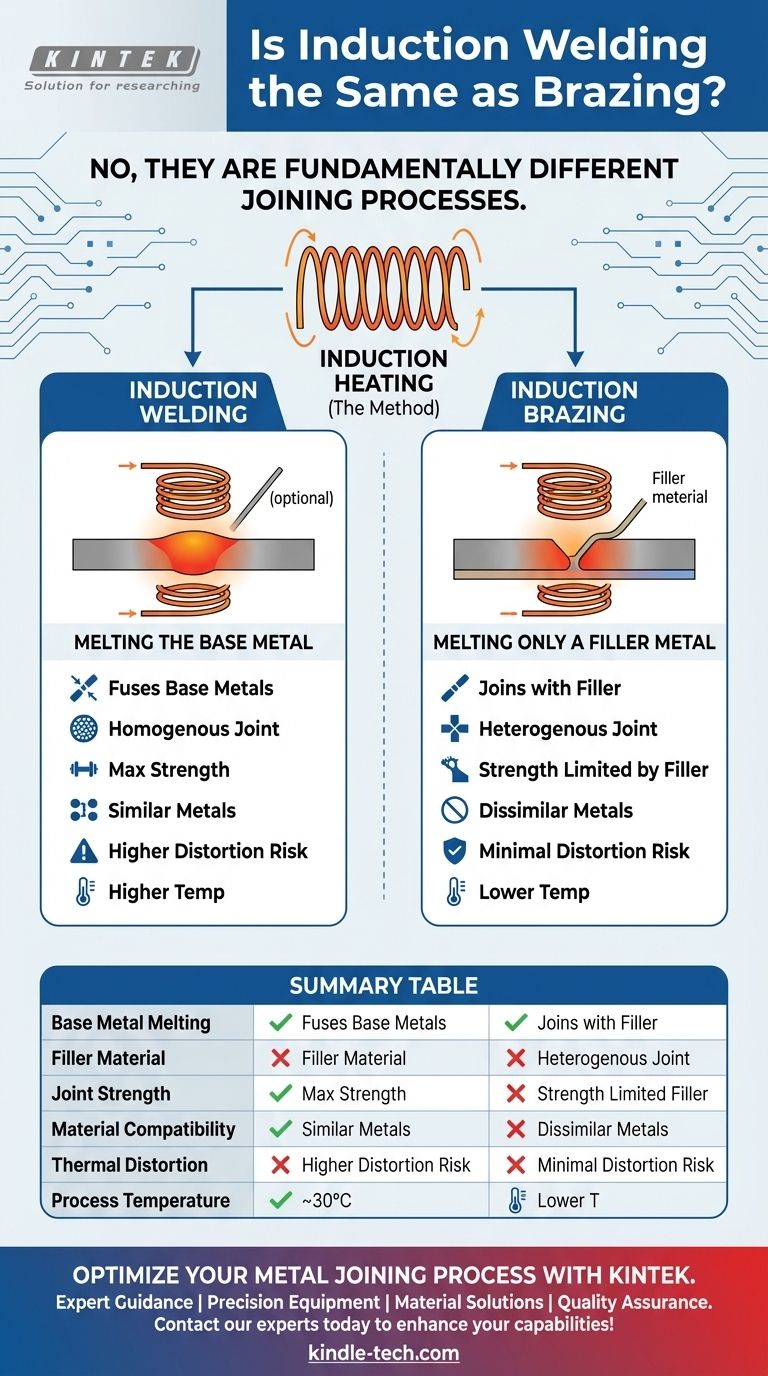

Summary Table:

| Feature | Induction Welding | Induction Brazing |

|---|---|---|

| Base Metal Melting | Melts base metals | Does not melt base metals |

| Filler Material | Optional filler | Required filler metal |

| Joint Strength | As strong as parent materials | Limited by filler metal strength |

| Material Compatibility | Best for similar metals | Excellent for dissimilar metals |

| Thermal Distortion | Higher risk | Minimal risk |

| Process Temperature | Higher (melting point of base metal) | Lower (melting point of filler) |

Optimize Your Metal Joining Process with KINTEK

Struggling to choose between induction welding and brazing for your specific application? Let KINTEK's expertise guide you to the perfect solution. Our specialized lab equipment and consumables are designed to deliver precise, repeatable results for all your metal joining needs.

Why choose KINTEK for your joining challenges?

- Expert Guidance: Get professional advice on selecting the right process for your materials and strength requirements

- Precision Equipment: Access industry-leading induction heating systems for both welding and brazing applications

- Material Solutions: Find the perfect consumables and filler metals for your specific joining tasks

- Quality Assurance: Achieve consistent, high-quality joints with our reliable laboratory solutions

Ready to enhance your metal joining capabilities? Contact our experts today for personalized recommendations and discover how KINTEK's laboratory solutions can transform your manufacturing process. Let's build stronger connections together!

Visual Guide

Related Products

- HFCVD Machine System Equipment for Drawing Die Nano-Diamond Coating

- Anti-Cracking Press Mold for Lab Use

- High Energy Vibratory Laboratory Ball Mill Grinding Mill Single Tank Type

- Single Punch Tablet Press Machine and Mass Production Rotary Tablet Punching Machine for TDP

- Laboratory Test Sieves and Sieving Machines

People Also Ask

- Which type of transformer is used in the induction furnace? Unlocking the Core Principle of Induction Heating

- What is the temperature range of induction heating? From Gentle Warming to Extreme Melting

- What are the cons of induction furnace? Understanding the Limitations of High-Speed Melting

- What are the components of an induction melting furnace? A Guide to the Core Systems

- Can induction furnace be used to prepare alloys by melting the metals? Yes, for Clean, Precise, and Homogenous Alloys

- What is vacuum arc melting process? A Guide to High-Purity Metal Production

- Can you melt metal to reuse it? Unlock the Secrets of Metal Casting and Recycling

- What is the role of a high-frequency induction melting furnace in ZrCu alloy synthesis? Achieve Maximum Purity