The short answer is an emphatic yes. Polytetrafluoroethylene (PTFE) is one of the most chemically inert and corrosion-resistant materials known to science. Its unique molecular structure makes it exceptionally stable, rendering it unaffected by nearly all common corrosive agents, including strong acids, alkalis, and organic solvents. This remarkable chemical stability is why PTFE is often referred to as the "plastic king" and is a default choice for a huge range of demanding applications.

The exceptional corrosion resistance of PTFE is not just a feature; it is a direct consequence of its fundamental chemical inertness. However, this near-universal resistance has specific, high-energy exceptions, and its mechanical properties under different conditions are just as critical to consider for any successful application.

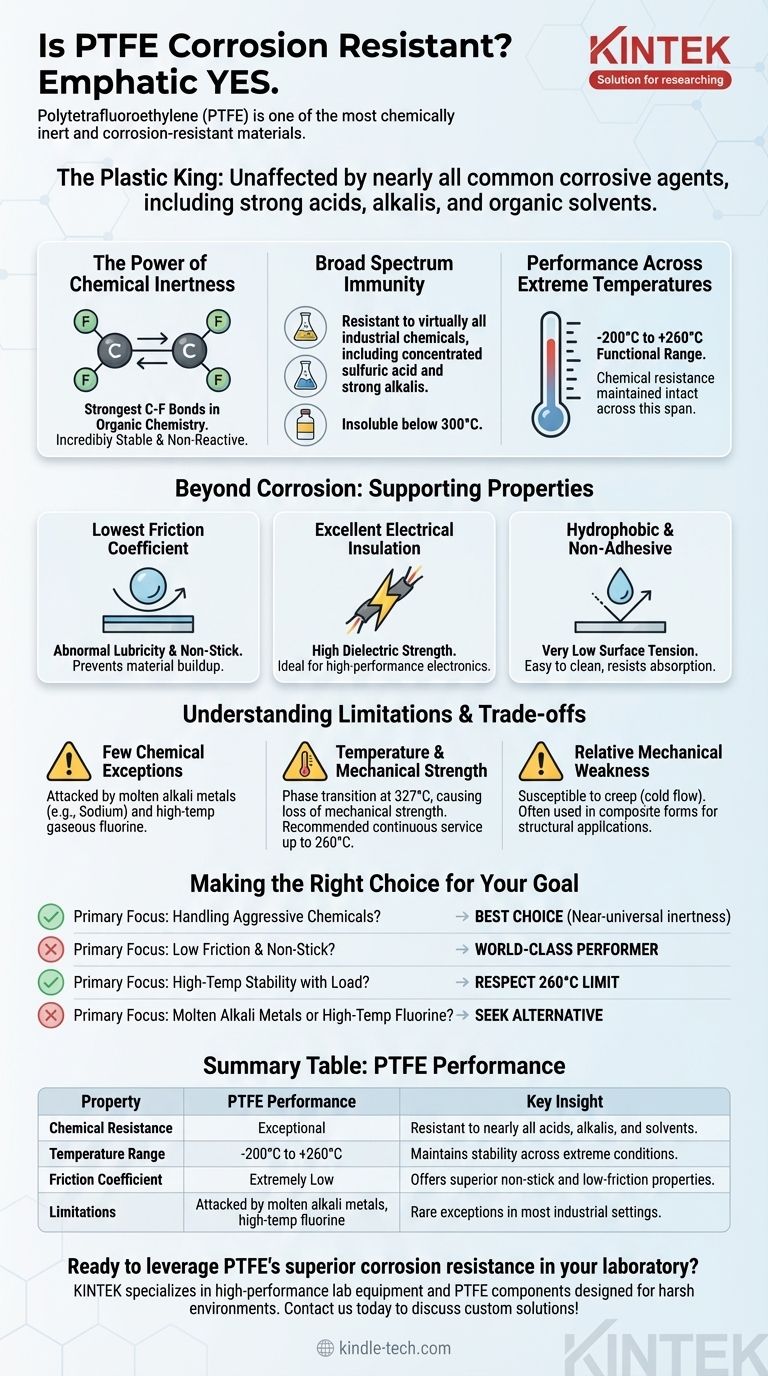

What Makes PTFE So Uniquely Resistant?

To understand why PTFE is so effective, we must look beyond a simple "resistant" label and examine the properties that grant it this immunity. It isn't just one feature, but a combination of characteristics that work in concert.

The Power of Chemical Inertness

At its core, PTFE is a simple polymer of carbon and fluorine. The carbon-fluorine bond is one of the strongest single bonds in organic chemistry, making the molecule incredibly stable and non-reactive.

This stability means that other chemicals, even highly aggressive ones, lack the energy or mechanism to break these bonds and cause degradation, which is the essence of chemical corrosion.

Broad Spectrum Immunity

Because of its inert nature, PTFE is resistant to virtually all industrial chemicals and solvents. This includes concentrated sulfuric acid, strong alkalis, and a vast array of organic compounds.

It is almost completely insoluble in any solvent below 300°C, making it a premier choice for seals, gaskets, and linings in chemical processing equipment.

Performance Across Extreme Temperatures

A material's corrosion resistance is only useful if it can be maintained under operational conditions. PTFE excels here, with a remarkably wide functional temperature range, typically cited from -200°C to +260°C.

Within this range, its chemical resistance remains almost entirely intact, unlike many materials that become more susceptible to chemical attack at higher temperatures.

Beyond Corrosion: The Supporting Properties of PTFE

While its chemical resistance is legendary, several other elite properties make PTFE a uniquely powerful material for engineering challenges.

The Lowest Friction Coefficient

PTFE possesses one of the lowest coefficients of friction of any solid material. This gives it an "abnormal lubricity" and creates an extremely non-stick surface.

This property is not only useful for bearings and low-friction coatings but also helps prevent material buildup on surfaces, which can be a secondary site for corrosion.

Excellent Electrical Insulation

PTFE is an outstanding electrical insulator with high dielectric strength. This, combined with its chemical and thermal resistance, makes it a critical material in high-performance wiring, cables, and electronic components exposed to harsh environments.

Hydrophobic and Non-Adhesive

The material has very low surface tension and is not "wetted" by water or oils. It is highly hydrophobic, resisting water absorption completely.

This non-adhesive quality makes it incredibly easy to clean and ensures that corrosive media do not cling to its surface.

Understanding the Limitations and Trade-offs

No material is perfect for every scenario. To use PTFE effectively, it is critical to understand its specific limitations. Being objective about these trade-offs is the mark of sound engineering.

The Few Chemical Exceptions

While almost universally inert, PTFE does have a few known vulnerabilities. It can be attacked by highly reactive substances like molten alkali metals (e.g., sodium), gaseous fluorine at high temperatures, and certain complex organic halides.

These exceptions are rare in most industrial processes but are critical to be aware of for specialized applications.

Temperature and Mechanical Strength

PTFE does not have a true melting point. At around 327°C, it undergoes a phase transition where its mechanical strength suddenly disappears. It begins to decompose slowly above 415°C.

While it is rated for continuous service up to 260°C, its structural integrity must be carefully considered for applications involving high temperatures combined with significant mechanical loads.

Relative Mechanical Weakness

Compared to metals or high-strength engineering plastics, PTFE is a relatively soft material. It is susceptible to creep (cold flow) under sustained load and has lower tensile strength and abrasion resistance.

For this reason, it is often used in composite forms (e.g., glass-filled or carbon-filled PTFE) to enhance its mechanical properties for structural or high-wear applications.

Making the Right Choice for Your Goal

To determine if PTFE is the correct material, evaluate your primary operational challenge against its specific strengths and weaknesses.

- If your primary focus is handling aggressive chemicals: PTFE is likely your best and safest choice due to its near-universal chemical inertness across a wide temperature range.

- If your primary focus is low friction and non-stick surfaces: PTFE is a world-class performer, providing exceptional lubricity and release properties unmatched by most other solid materials.

- If your primary focus is high-temperature stability with mechanical load: You must respect its 260°C continuous service limit and engineer around its tendency to lose strength at higher temperatures.

- If your environment involves molten alkali metals or high-temp fluorine: You must seek an alternative material, as this is one of the few scenarios where PTFE will be chemically attacked.

Understanding both its profound strengths and its specific limitations is the key to leveraging PTFE effectively in any design.

Summary Table:

| Property | PTFE Performance | Key Insight |

|---|---|---|

| Chemical Resistance | Exceptional | Resistant to nearly all acids, alkalis, and solvents. |

| Temperature Range | -200°C to +260°C | Maintains stability across extreme conditions. |

| Friction Coefficient | Extremely Low | Offers superior non-stick and low-friction properties. |

| Limitations | Attacked by molten alkali metals, high-temp fluorine | Rare exceptions in most industrial settings. |

Ready to leverage PTFE's superior corrosion resistance in your laboratory? KINTEK specializes in high-performance lab equipment and consumables, including PTFE components designed to withstand the harshest chemical environments. Whether you need durable seals, linings, or custom solutions, our expertise ensures your lab operates with maximum safety and efficiency. Contact us today to discuss how our PTFE products can solve your specific challenges!

Visual Guide

Related Products

- Custom PTFE Teflon Parts Manufacturer for Hydrothermal Synthesis Reactor Polytetrafluoroethylene Carbon Paper and Carbon Cloth Nano-growth

- Custom PTFE Teflon Parts Manufacturer for PTFE Bottle Oil Fume Sampling Tube

- Custom PTFE Teflon Parts Manufacturer for Non-Standard Insulator Customization

- Custom PTFE Teflon Parts Manufacturer for Cleaning Racks

- Custom PTFE Teflon Parts Manufacturer for Culture Dish and Evaporation Dish

People Also Ask

- Why is PTFE the lining material for hydrothermal reactors? Ensure Purity in Magnéli Phase Synthesis

- What is the function of PTFE in a gas diffusion electrode? Mastering CO2 Electrolyzer Stability

- What technical advantages does a PTFE-based flow reaction platform offer? Speed Up Lignin Depolymerization by 95%

- What are the advantages of using PTFE plates for NIPU films? Achieve Superior Mold Release and Purity

- What is the primary purpose of coating the GDL with PTFE in HCl electrolysis? Enhance Gas Diffusion & Prevent Flooding

- Why is adhesive PTFE tape used for sealing aluminum alloy specimens? Ensure Precision in Microbial Corrosion Studies

- What role does Polytetrafluoroethylene (PTFE) play in MEC electrodes? Optimize Your Catalyst Coating for Performance

- How are PTFE (Teflon) guide sleeves utilized within battery molds? Ensure Safe Solid-State Battery Assembly