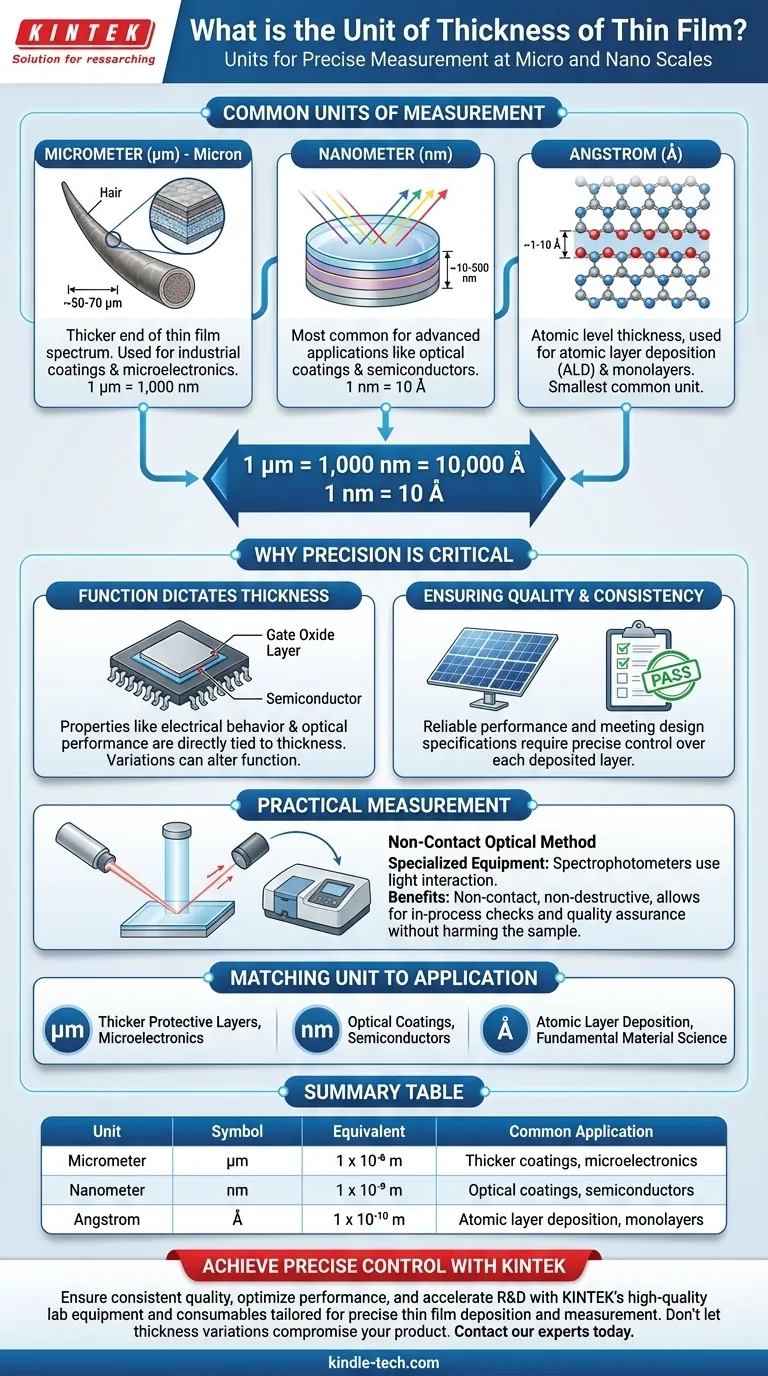

The thickness of a thin film is most commonly measured in nanometers (nm), micrometers (µm), and angstroms (Å). The specific unit chosen depends entirely on the thickness of the layer and the precision required for its application, which can range from a single layer of atoms to thousands of atomic layers thick.

The unit used for thin film thickness is not singular; it is chosen to match the scale of the application. The critical insight is that these measurements reflect a scale where even minuscule variations in thickness can drastically alter a material's fundamental properties.

Understanding the Scale of Thin Film Units

To work with thin films, you must first develop an intuition for the incredibly small scales involved. The units are chosen to make the numbers manageable and meaningful for a given context.

The Micrometer (µm)

A micrometer, also known as a micron, is one-millionth of a meter. This unit is typically used for the "thicker" end of the thin film spectrum.

Many industrial coatings or layers in microelectronic devices are measured in micrometers. For context, a typical human hair is about 50-70 µm in diameter.

The Nanometer (nm)

The nanometer is the most frequently used unit for advanced thin film applications, such as optical coatings and semiconductor devices. One nanometer is one-billionth of a meter.

There are 1,000 nanometers in one micrometer. A film described as 0.5 µm thick is identical to one that is 500 nm thick.

The Angstrom (Å)

The angstrom is the smallest of the common units, representing one-tenth of a nanometer (or one ten-billionth of a meter).

This unit is used when discussing thicknesses at the atomic level, such as in atomic layer deposition or when describing a monolayer (a single layer of atoms). There are 10 angstroms in one nanometer.

Why This Precision is Critical

Measuring thin film thickness is not an academic exercise; it is essential for controlling the final product's function and performance.

Function Dictates Thickness

The physical, optical, and electrical properties of a thin film are directly tied to its thickness.

For an optical coating on a lens, a difference of just a few nanometers can change which wavelengths of light are reflected or transmitted, altering the color and performance. In semiconductors, the thickness of gate oxides determines the device's electrical behavior.

Ensuring Quality and Consistency

To manufacture products with reliable performance, from solar panels to microchips, the thickness of each deposited layer must be precisely controlled.

Accurate measurement ensures that every product meets its design specifications and functions optimally.

The Practicalities of Measurement

Given the microscopic scale, specialized equipment is required to measure thin film thickness accurately without damaging the sample.

Non-Contact Optical Methods

Tools like spectrophotometers are widely used because they are non-contact and non-destructive. They analyze how light interacts with the film to calculate its thickness.

This optical approach is crucial for in-process checks and quality control, as it doesn't harm the delicate component being measured.

The Value of Non-Destructive Testing

The ability to measure a film without touching or destroying it is paramount. It allows for quality assurance on finished products and real-time monitoring during the deposition process itself.

Matching the Unit to the Application

Your choice of unit simply reflects the world you are working in. Use this as your guide:

- If your primary focus is on optical coatings or semiconductors: You will primarily work in nanometers (nm), as precise control at this level determines the film's functional properties.

- If your primary focus is on thicker protective layers or microelectronics: Micrometers (µm or microns) will be your standard unit of measurement.

- If your primary focus is on atomic layer deposition or fundamental materials science: You will encounter angstroms (Å) to describe thicknesses approaching a single layer of atoms.

Understanding this scale is the first step toward controlling the unique physical properties that emerge in thin films.

Summary Table:

| Unit | Symbol | Equivalent | Common Application |

|---|---|---|---|

| Micrometer | µm | 1 x 10⁻⁶ m | Thicker coatings, microelectronics |

| Nanometer | nm | 1 x 10⁻⁹ m | Optical coatings, semiconductors |

| Angstrom | Å | 1 x 10⁻¹⁰ m | Atomic layer deposition, monolayers |

Achieve precise control over your thin film processes with KINTEK.

Whether you are developing advanced optical coatings, semiconductor devices, or protective layers, the accuracy of your film's thickness is paramount. KINTEK specializes in providing high-quality lab equipment and consumables tailored for precise thin film deposition and measurement.

Our solutions help you ensure consistent quality, optimize performance, and accelerate your R&D and production. Don't let thickness variations compromise your product's functionality.

Contact our experts today to discuss how KINTEK can support your laboratory's specific thin film needs.

Visual Guide

Related Products

- Electron Beam Evaporation Coating Oxygen-Free Copper Crucible and Evaporation Boat

- Custom CVD Diamond Coating for Lab Applications

- CVD Diamond Domes for Industrial and Scientific Applications

- Customer Made Versatile CVD Tube Furnace Chemical Vapor Deposition Chamber System Equipment

- Vacuum Hot Press Furnace Machine for Lamination and Heating

People Also Ask

- What is the container that holds the metal source material called in e-beam evaporation? Ensure Purity and Quality in Your Thin-Film Deposition

- Can I solder copper to copper without flux? The Critical Role of Flux for a Strong Bond

- What is electron beam coating? A Guide to High-Performance PVD Thin Films

- What is sputter coating used for? Achieve Superior Thin Films for Electronics, Optics, and Tools

- How thick is the sputter coating for SEM? Achieve Optimal Imaging & Analysis