Yes, PVD coating is exceptionally durable. It creates a surface finish that is significantly harder and more resistant to wear, corrosion, and scratches than virtually any traditional coating method. This durability comes from a process that molecularly bonds the coating to the underlying material, creating a super-hard barrier that is part of the object itself, not just a layer on top.

The core reason for PVD's durability is not just the hardness of the coating, but the integrity of the bond it forms with the substrate. This creates a unified surface that enhances the properties of the original material on a molecular level.

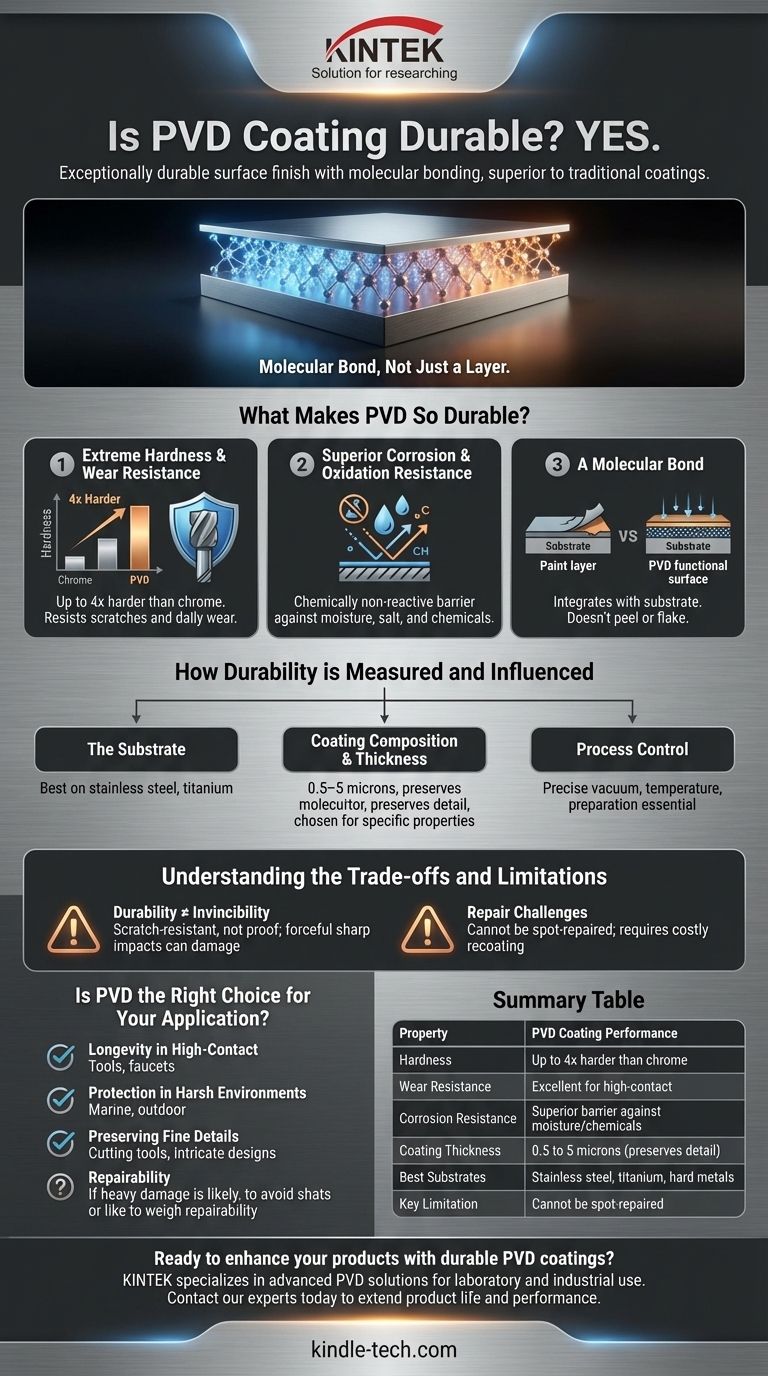

What Makes PVD So Durable?

PVD, or Physical Vapor Deposition, is not a simple liquid coating. It is a high-tech vacuum deposition process that creates an incredibly robust and long-lasting finish.

A Molecular Bond, Not a Layer of Paint

Unlike painting or plating, which apply a distinct layer on top of a material, PVD integrates the coating with the substrate. In the PVD process, a solid material is vaporized in a vacuum and deposited, atom by atom, onto the surface of the part.

This creates a strong, atomic bond. The resulting finish is not something that can easily peel or flake away; it has become a new, functional part of the surface.

Extreme Hardness and Wear Resistance

PVD coatings are renowned for their hardness. Many common PVD finishes, like Titanium Nitride (TiN), are ceramic-based and significantly harder than the metals they cover.

In fact, PVD coatings are often cited as being up to four times harder than chrome. This translates directly to superior resistance against scratches and the daily wear and tear that degrades other finishes.

Superior Corrosion and Oxidation Resistance

The PVD process creates a thin, dense film that is chemically non-reactive. This film acts as an effective barrier, sealing the substrate material from exposure to moisture, salt, and atmospheric chemicals.

This makes PVD an ideal choice for components exposed to harsh environments, such as architectural hardware near the coast or items that are frequently in contact with human skin.

How Durability is Measured and Influenced

The final durability of a PVD-coated product is a function of several factors, not just the coating itself.

The Critical Role of the Substrate

The foundation of a durable P_V_D finish is the material underneath it. A hard coating on a soft substrate will not prevent dents.

PVD works best when applied to hard materials like stainless steel or titanium. The coating enhances the inherent strength of the base material, creating a synergistic system where the whole is greater than the sum of its parts.

Coating Composition and Thickness

PVD coatings are very thin, typically ranging from 0.5 to 5 microns. This thinness is an advantage, as it preserves the original surface texture and sharp edges of an object, which is critical for cutting tools and intricate designs.

The specific material used for the coating (e.g., Titanium Nitride, Zirconium Nitride) is chosen based on the desired properties, such as hardness, color, and lubricity.

The Importance of Process Control

Achieving maximum durability relies on precise control over the PVD process. Factors like temperature, pressure within the vacuum chamber, and surface preparation are all critical.

A poorly prepared surface or an improperly controlled deposition will result in poor adhesion, undermining the entire benefit of the coating.

Understanding the Trade-offs and Limitations

While incredibly durable, PVD is not indestructible. Understanding its limits is key to using it effectively.

Durability Is Not Invincibility

PVD coatings are highly scratch-resistant, but they are not scratch-proof. A forceful, sharp impact with an object harder than the coating can still cause a scratch or chip.

While it will withstand daily abrasion far better than other finishes, it will not make a product immune to determined or aggressive physical damage.

Repair Challenges

This is the most significant trade-off. If a PVD coating does get damaged, it cannot be spot-repaired like a layer of paint.

Repairing the damage typically requires the entire object to be chemically stripped of the old coating and then completely recoated. This process can be costly and is not always feasible.

Is PVD the Right Choice for Your Application?

Choosing PVD depends entirely on your project's priorities.

- If your primary focus is longevity for high-contact items: PVD is an ideal choice for products like tools, faucets, and watch bracelets due to its exceptional hardness and wear resistance.

- If your primary focus is protection from harsh environments: Its superior corrosion resistance makes PVD a top-tier solution for marine hardware or outdoor architectural fixtures.

- If your primary focus is preserving fine details or sharp edges: The thin nature of PVD makes it perfect for adding durability to cutting tools or intricate jewelry without dulling critical features.

- If your primary focus is a project where repairability after heavy damage is key: You may need to weigh the trade-offs, as repairing a severely damaged PVD coating can be complex and expensive.

Ultimately, PVD coating offers a level of durability that traditional methods cannot match, making it the superior choice for applications where performance and longevity are paramount.

Summary Table:

| Property | PVD Coating Performance |

|---|---|

| Hardness | Up to 4x harder than chrome |

| Wear Resistance | Excellent for high-contact items |

| Corrosion Resistance | Superior barrier against moisture and chemicals |

| Coating Thickness | 0.5 to 5 microns (preserves detail) |

| Best Substrates | Stainless steel, titanium, hard metals |

| Key Limitation | Cannot be spot-repaired if damaged |

Ready to enhance your products with durable PVD coatings? KINTEK specializes in advanced PVD solutions for laboratory equipment, industrial tools, and precision components. Our coatings provide molecular-level bonding that significantly extends product life and performance. Contact our experts today to discuss how PVD technology can solve your durability challenges!

Visual Guide

Related Products

- RF PECVD System Radio Frequency Plasma-Enhanced Chemical Vapor Deposition RF PECVD

- Chemical Vapor Deposition CVD Equipment System Chamber Slide PECVD Tube Furnace with Liquid Gasifier PECVD Machine

- Split Chamber CVD Tube Furnace with Vacuum Station Chemical Vapor Deposition System Equipment Machine

- VHP Sterilization Equipment Hydrogen Peroxide H2O2 Space Sterilizer

- Molybdenum Tungsten Tantalum Special Shape Evaporation Boat

People Also Ask

- What are the benefits of PECVD? Achieve Superior Low-Temperature Thin Film Deposition

- What are the applications of PECVD? Essential for Semiconductors, MEMS, and Solar Cells

- Why does PECVD commonly use RF power input? For Precise Low-Temperature Thin Film Deposition

- What are the advantages of PECVD? Enable Low-Temperature, High-Quality Thin-Film Deposition

- How does RF power create plasma? Achieve Stable, High-Density Plasma for Your Applications