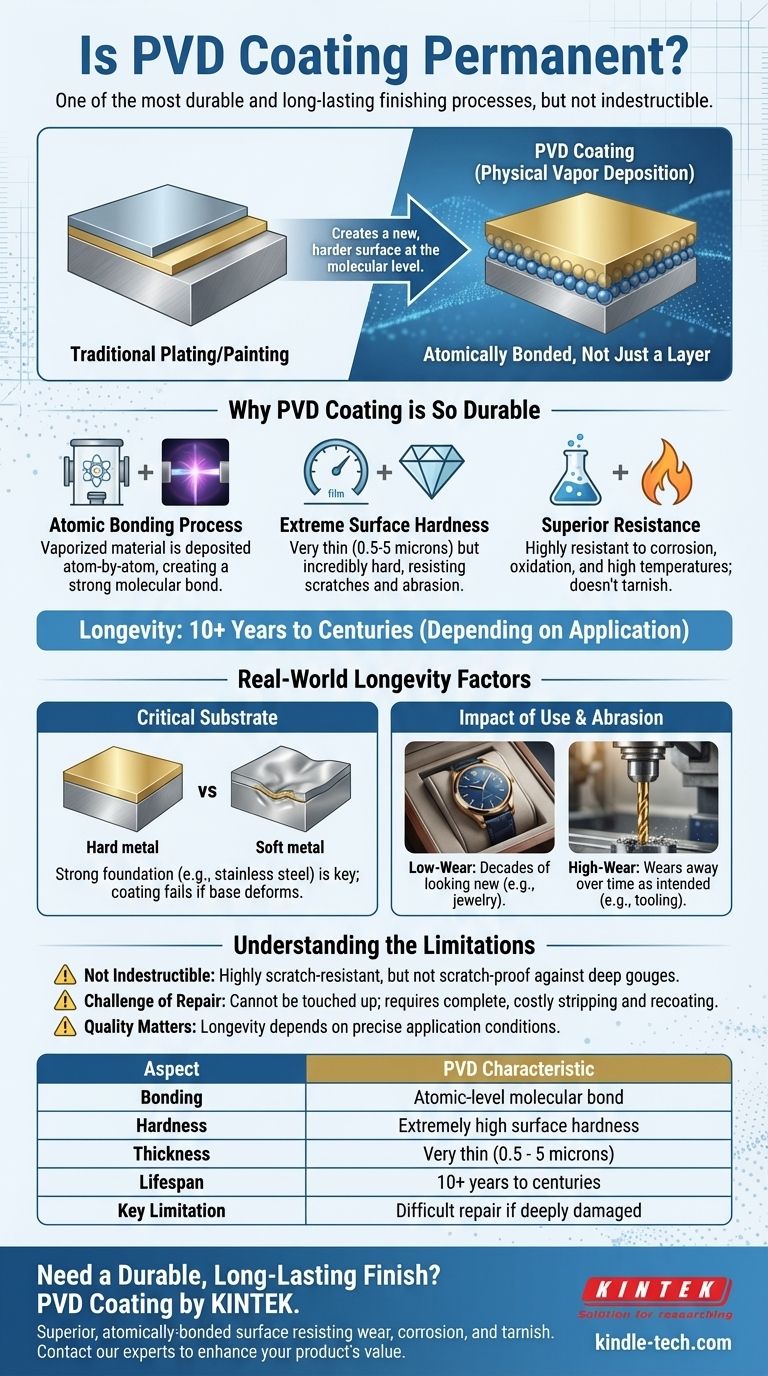

PVD coating is not technically permanent, but it is one of the most durable and long-lasting finishing processes available. For most practical applications, it can be considered a lifetime finish. The lifespan can range from over ten years to centuries, as the process creates a new, atomically bonded surface layer on the base material, making it far more resilient than traditional plating or painting.

The core idea to grasp is that PVD is not a layer of paint on a surface; it's a new, harder surface created at the molecular level. Its exceptional longevity comes from its incredible hardness and resistance to wear, not from being truly indestructible.

What Makes PVD Coating So Durable?

Physical Vapor Deposition (PVD) creates a finish that is fundamentally different from traditional coatings. This difference is the source of its remarkable durability.

The Atomic Bonding Process

PVD is a high-temperature vacuum process where a solid material (like titanium) is vaporized into a plasma. This vapor is then deposited, one atom at a time, onto the target object.

This method creates a molecular bond between the coating and the substrate. It's less like painting a wall and more like fusing a new, harder material directly onto the wall's surface.

A Matter of Hardness, Not Thickness

PVD coatings are extremely thin, typically ranging from just 0.5 to 5 microns. Their durability doesn't come from thickness but from immense surface hardness.

This hardness provides extreme resistance to the scratches, abrasion, and daily wear that would quickly degrade other finishes.

Superior Corrosion and Chemical Resistance

The resulting layer is highly resistant to corrosion, oxidation, and high temperatures. This chemical stability ensures the finish will not tarnish or fade from exposure to sweat, salt air, or other common environmental factors.

Factors That Define Longevity in the Real World

While extremely tough, the actual lifespan of a PVD coating is not infinite. It depends heavily on the quality of the application and the environment it's used in.

The Critical Role of the Substrate

The PVD coating relies on the strength of the material underneath it. A coating is only as strong as its foundation.

For this reason, PVD is most effective when applied to hard substrates like stainless steel, titanium, or tool-grade steel. If the base metal deforms or dents, the PVD layer on top will be compromised.

The Impact of Use and Abrasion

The lifespan of the coating is directly related to the amount of friction and wear it endures.

A PVD-coated watch case, which sees only occasional contact, may look new for decades. A PVD-coated industrial drill bit, however, is designed for constant, high-friction use and its coating will eventually wear away as intended.

Understanding the Limitations

Trust in a technology requires understanding its boundaries. While PVD is a superior process, it is not without its limitations.

It Is Not Indestructible

PVD is highly scratch-resistant, but it is not scratch-proof. A deep gouge from a sharp, hard object that damages the underlying substrate will also damage the coating.

The Challenge of Repair

If a PVD coating does sustain significant damage, it cannot be "touched up" like paint. The entire object must be professionally stripped and recoated in a vacuum chamber, which can be a complex and costly process.

Quality of Application is Key

The durability of the finish is highly dependent on the quality control of the PVD process. Factors like temperature, vacuum pressure, and surface preparation must be perfect. Not all PVD applications are created equal.

Making the Right Choice for Your Goal

Your decision should be based on the balance between the expected wear of the product and your desire for a long-lasting, resilient finish.

- If your primary focus is aesthetics and daily wear (e.g., watches, faucets, jewelry): PVD offers a finish that will likely outlast the product itself, resisting scratches and tarnish far better than any traditional method.

- If your primary focus is high-performance tooling (e.g., drill bits, industrial parts): PVD provides a critical wear-resistant layer that extends the tool's functional life, but it should be viewed as a durable, sacrificial surface.

- If your primary focus is a simple color change without extreme durability needs: Less advanced finishes may suffice, but they will not provide the same level of hardness or resistance to wear and corrosion.

By creating an entirely new, atomically-bonded surface, PVD offers a level of durability that makes it one of the most permanent finishing solutions available today.

Summary Table:

| Aspect | PVD Coating Characteristic |

|---|---|

| Bonding | Atomic-level molecular bond with the substrate |

| Hardness | Extremely high surface hardness for wear resistance |

| Thickness | Very thin (0.5 - 5 microns) |

| Lifespan | 10+ years to centuries, depending on application |

| Key Limitation | Cannot be easily repaired if deeply damaged |

Need a Durable, Long-Lasting Finish for Your Products or Tools?

PVD coating from KINTEK provides a superior, atomically-bonded surface that resists wear, corrosion, and tarnish far better than traditional methods. Whether you're developing high-performance industrial components, durable consumer goods, or precision laboratory equipment, our expertise ensures a flawless, long-lasting finish.

Contact our experts today to discuss how PVD coating can enhance the durability and value of your products.

Visual Guide

Related Products

- RF PECVD System Radio Frequency Plasma-Enhanced Chemical Vapor Deposition RF PECVD

- Chemical Vapor Deposition CVD Equipment System Chamber Slide PECVD Tube Furnace with Liquid Gasifier PECVD Machine

- Split Chamber CVD Tube Furnace with Vacuum Station Chemical Vapor Deposition System Equipment Machine

- VHP Sterilization Equipment Hydrogen Peroxide H2O2 Space Sterilizer

- Molybdenum Tungsten Tantalum Special Shape Evaporation Boat

People Also Ask

- Why is PECVD environment friendly? Understanding the Eco-Friendly Benefits of Plasma-Enhanced Coating

- Why does PECVD commonly use RF power input? For Precise Low-Temperature Thin Film Deposition

- What is the principle of plasma enhanced chemical vapor deposition? Achieve Low-Temperature Thin Film Deposition

- What are the applications of PECVD? Essential for Semiconductors, MEMS, and Solar Cells

- What are the benefits of PECVD? Achieve Superior Low-Temperature Thin Film Deposition