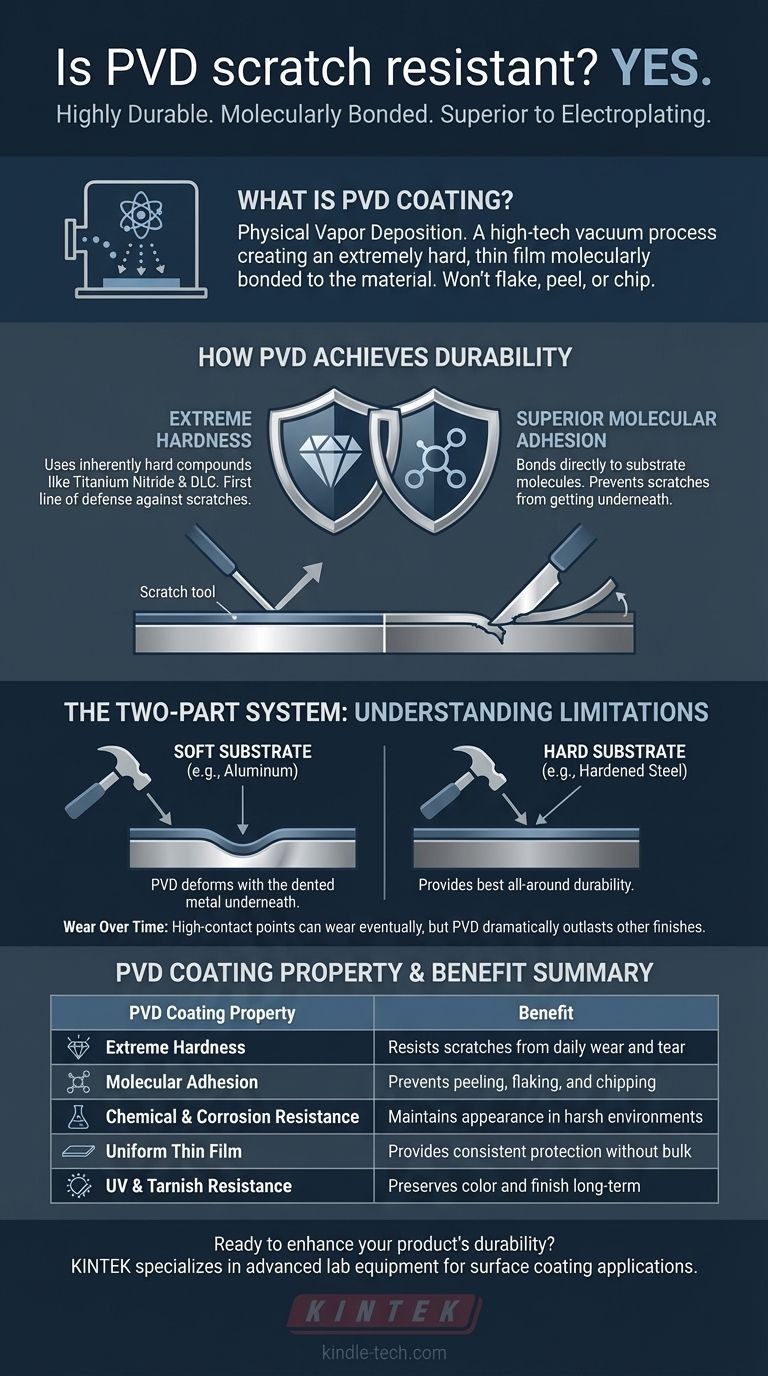

Yes, PVD coatings are highly scratch-resistant. This durability comes from the process itself, which creates an extremely hard, thin film that is molecularly bonded to the surface of the underlying material. As a result, PVD is significantly more resistant to scuffs, scratches, and everyday wear than traditional coatings like electroplating or paint.

The key to understanding PVD durability is realizing it's a two-part system: the hard coating and the base material it protects. While the coating itself is exceptionally scratch-resistant, its overall effectiveness depends heavily on the hardness of the material underneath it.

What is PVD Coating?

PVD, or Physical Vapor Deposition, is a sophisticated vacuum coating process. It's not paint or a chemical bath; it's a high-tech procedure that bonds a coating to a material at the atomic level.

The Deposition Process

In simple terms, a solid coating material (like titanium or graphite) is vaporized in a vacuum chamber. This vapor then travels and deposits onto the object being coated, forming a very thin, perfectly uniform, and tightly bonded layer.

The Result: A Superior Finish

This process results in a coating that is characterized by its high purity and exceptional adhesion. Because it's bonded molecularly, it won't flake, peel, or chip like a traditional painted or plated finish.

Key Characteristics

PVD coatings are valued for being much harder and more corrosion-resistant than coatings applied by older methods like electroplating. They also offer excellent chemical resistance and are produced through an environmentally clean process.

How PVD Achieves Its Durability

The remarkable scratch resistance of PVD isn't due to a single factor, but rather the combination of two critical properties: hardness and adhesion.

Extreme Hardness

The materials used for PVD coatings, such as titanium nitride and diamond-like carbon (DLC), are inherently very hard compounds. This intrinsic hardness provides the first line of defense, making the surface difficult to scratch in the first place.

Superior Molecular Adhesion

Because the PVD process bonds the coating directly to the substrate's molecules, the finish becomes a part of the surface itself. This prevents a scratch from getting underneath the coating and causing it to peel away, a common failure point for lesser coatings.

Understanding the Trade-offs and Limitations

While PVD is a superior coating, it is not indestructible. Understanding its limitations is crucial for setting realistic expectations.

A Coating Is Still a Coating

PVD adds a protective layer measured in microns; it does not change the fundamental properties of the base material. A hard coating on a soft metal can still be damaged.

The Substrate Is Critical

This is the most important concept to grasp. If you apply a hard PVD coating to a soft base metal like aluminum or 316L stainless steel, a strong impact can still dent the object. The PVD coating may not scratch through, but it will deform along with the dented metal underneath.

Wear Over Time

On high-contact points, like the clasp of a watch bracelet or the sharp edge of a tool, extreme and persistent abrasion can eventually wear through the coating over many years. However, for most daily uses, it will dramatically outlast other finishes.

Making the Right Choice for Your Goal

PVD is an exceptional choice for adding durability and color to a product, but its effectiveness is tied to your specific goal.

- If your primary focus is daily wear and tear: PVD offers outstanding protection against the scuffs and light scratches that degrade most products, making it ideal for watches, jewelry, and hardware.

- If your primary focus is maximum impact resistance: Pay attention to the base material. A PVD coating on a hard substrate like titanium or hardened steel will provide the best all-around durability.

- If your primary focus is aesthetic longevity: PVD provides a long-lasting, uniform finish that resists fading from UV light, corrosion from sweat, and tarnishing far better than any traditional plating.

Ultimately, choosing a PVD-coated product is choosing an advanced, engineered surface designed for superior longevity and resilience.

Summary Table:

| PVD Coating Property | Benefit |

|---|---|

| Extreme Hardness | Resists scratches from daily wear and tear |

| Molecular Adhesion | Prevents peeling, flaking, and chipping |

| Chemical & Corrosion Resistance | Maintains appearance in harsh environments |

| Uniform Thin Film | Provides consistent protection without bulk |

| UV & Tarnish Resistance | Preserves color and finish long-term |

Ready to enhance your product's durability with professional PVD coating solutions? KINTEK specializes in advanced lab equipment and consumables for surface coating applications. Our expertise ensures your products benefit from superior scratch resistance, longevity, and aesthetic appeal. Contact us today to discuss how our PVD solutions can meet your specific laboratory or manufacturing needs!

Visual Guide

Related Products

- Custom CVD Diamond Coating for Lab Applications

- RF PECVD System Radio Frequency Plasma-Enhanced Chemical Vapor Deposition RF PECVD

- Vacuum Hot Press Furnace Machine for Lamination and Heating

- Split Chamber CVD Tube Furnace with Vacuum Station Chemical Vapor Deposition System Equipment Machine

- Molybdenum Disilicide (MoSi2) Thermal Elements Electric Furnace Heating Element

People Also Ask

- Is diamond coating worth it? Maximize Component Life and Performance

- What are the three types of coating? A Guide to Architectural, Industrial, and Special Purpose

- What is CVD diamond coating? Grow a Super-Hard, High-Performance Diamond Layer

- What are diamond coated films? Enhance Materials with Super-Hard, Transparent Layers

- Is diamond coating permanent? The Truth About Its Long-Lasting Durability