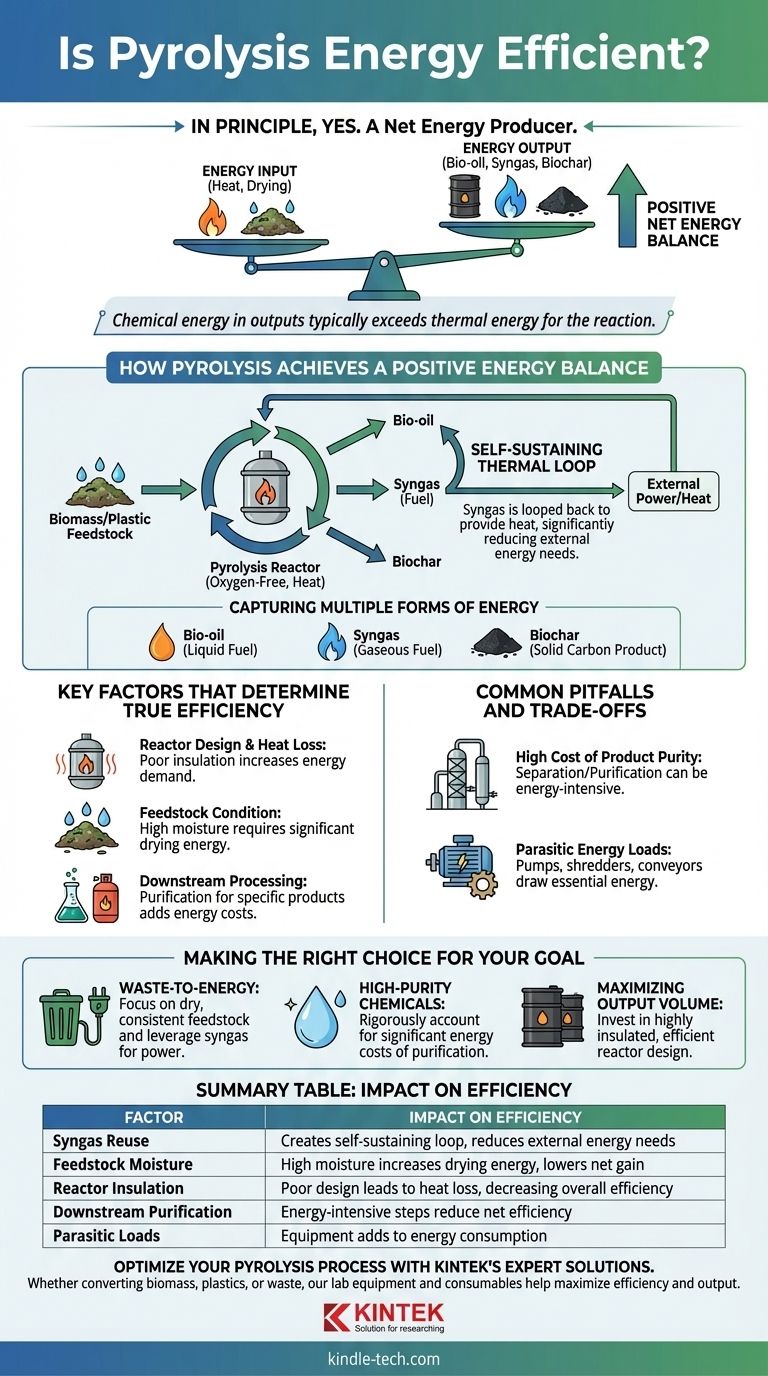

In principle, yes. Pyrolysis is generally considered an energy-efficient process because it is designed to be a net energy producer. The chemical energy contained in its outputs—such as bio-oil and syngas—typically exceeds the thermal energy required to heat the feedstock and drive the reaction.

The core measure of pyrolysis efficiency is its net energy balance. An efficient system generates more energy in its final products than it consumes for heating, drying feedstock, and post-processing, with the syngas produced often being used to make the process self-sustaining.

How Pyrolysis Achieves a Positive Energy Balance

Pyrolysis breaks down materials like biomass or plastic in an oxygen-free environment using heat. While it requires an initial energy input, the process is designed to create a value chain where the outputs are energy carriers themselves.

The Self-Sustaining Thermal Loop

The most critical factor for efficiency is the use of the non-condensable gases (syngas) produced during the reaction.

This syngas is a fuel. In well-designed systems, a portion of this gas is looped back and burned to provide the heat needed to sustain the pyrolysis reaction, significantly reducing or eliminating the need for external energy sources once the process is running.

Capturing Multiple Forms of Energy

Pyrolysis doesn't just produce one output; it creates a portfolio of valuable products.

The primary outputs are bio-oil (a liquid fuel), syngas (a gaseous fuel), and biochar (a solid carbon product). The combined chemical energy of these products is the "energy output" that must be weighed against the system's "energy input."

Key Factors That Determine True Efficiency

The statement that pyrolysis is "energy-efficient" is a general rule, not an absolute guarantee. The actual net energy gain or loss depends heavily on the specifics of the system and its goals.

Reactor Design and Heat Loss

An industrial-scale pyrolysis unit is a complex thermal system. Process-specific heat loss from poorly insulated reactors or inefficient heat transfer mechanisms can drastically increase the energy required to maintain reaction temperatures, lowering overall efficiency.

Feedstock Condition

The composition and moisture content of the raw material (feedstock) are critical. Processing wet biomass requires a significant amount of energy upfront for drying before the pyrolysis reaction can even begin, which can heavily impact the net energy balance.

Downstream Processing Requirements

The intended use of the final products matters immensely. If the goal is simply to produce a liquid fuel, the process is straightforward.

However, if the goal is to produce high-purity hydrogen from methane pyrolysis, the energy costs of separating it from other hydrocarbons and compressing it for storage must be factored in, which can lower the net efficiency.

Common Pitfalls and Trade-offs

Achieving high efficiency requires careful engineering to overcome common challenges. A failure to account for these factors is the primary reason a pyrolysis project can become an energy consumer instead of a producer.

The High Cost of Product Purity

Side reactions are common in pyrolysis, creating a mix of compounds. If a specific, pure chemical is the desired output, the subsequent separation and purification steps can be extremely energy-intensive, sometimes consuming more energy than the pyrolysis process itself.

Parasitic Energy Loads

Beyond the core reactor, "parasitic" energy loads include the power needed for shredders, conveyors, pumps, and pollution control systems. These essential components all draw energy and must be included in any honest energy efficiency calculation.

Making the Right Choice for Your Goal

Ultimately, the energy efficiency of a pyrolysis system is determined by its design and its intended application.

- If your primary focus is waste-to-energy: Pyrolysis can be highly efficient, especially if you use dry, consistent feedstock and leverage the produced syngas to power the operation.

- If your primary focus is producing high-purity chemicals: You must rigorously account for the significant energy costs of downstream purification, which will define the true net efficiency of the entire process.

- If your primary focus is maximizing output volume: The key is investing in a highly insulated and efficient reactor design to minimize thermal loss and ensure as much feedstock as possible is converted to valuable products.

A properly engineered pyrolysis system is a powerful tool for converting waste into value, but its efficiency is a direct result of the system's design and alignment with its specific purpose.

Summary Table:

| Factor | Impact on Efficiency |

|---|---|

| Syngas Reuse | Creates a self-sustaining thermal loop, reducing external energy needs |

| Feedstock Moisture | High moisture increases energy for drying, lowering net gain |

| Reactor Insulation | Poor design leads to heat loss, decreasing overall efficiency |

| Downstream Purification | Energy-intensive steps for pure chemicals can reduce net efficiency |

| Parasitic Loads | Equipment like conveyors and pumps add to energy consumption |

Optimize your pyrolysis process with KINTEK's expert solutions. Whether you're converting biomass, plastics, or other waste streams into energy, our lab equipment and consumables help you maximize efficiency and output. Contact us today to design a system that turns your feedstock into sustainable value!

Visual Guide

Related Products

- Small Vacuum Heat Treat and Tungsten Wire Sintering Furnace

- Double Layer Five-Port Water Bath Electrolytic Electrochemical Cell

- Vacuum Hot Press Furnace Machine for Lamination and Heating

- Quartz Electrolytic Electrochemical Cell for Electrochemical Experiments

- Laboratory Hybrid Tissue Grinding Mill

People Also Ask

- What is a magnetron sputtering? A Guide to High-Quality Thin-Film Deposition

- How does a sputtering machine work? Achieve Atomic-Level Precision for Your Coatings

- What is the role of the hydraulic system in hot pressing? Achieve Maximum Material Density and Strength

- What is liquid phase sintering and how is it different from solid state sintering? A Guide to Faster, Denser Materials

- What is magnetron sputtering machine? Precision Thin-Film Deposition for Advanced Materials