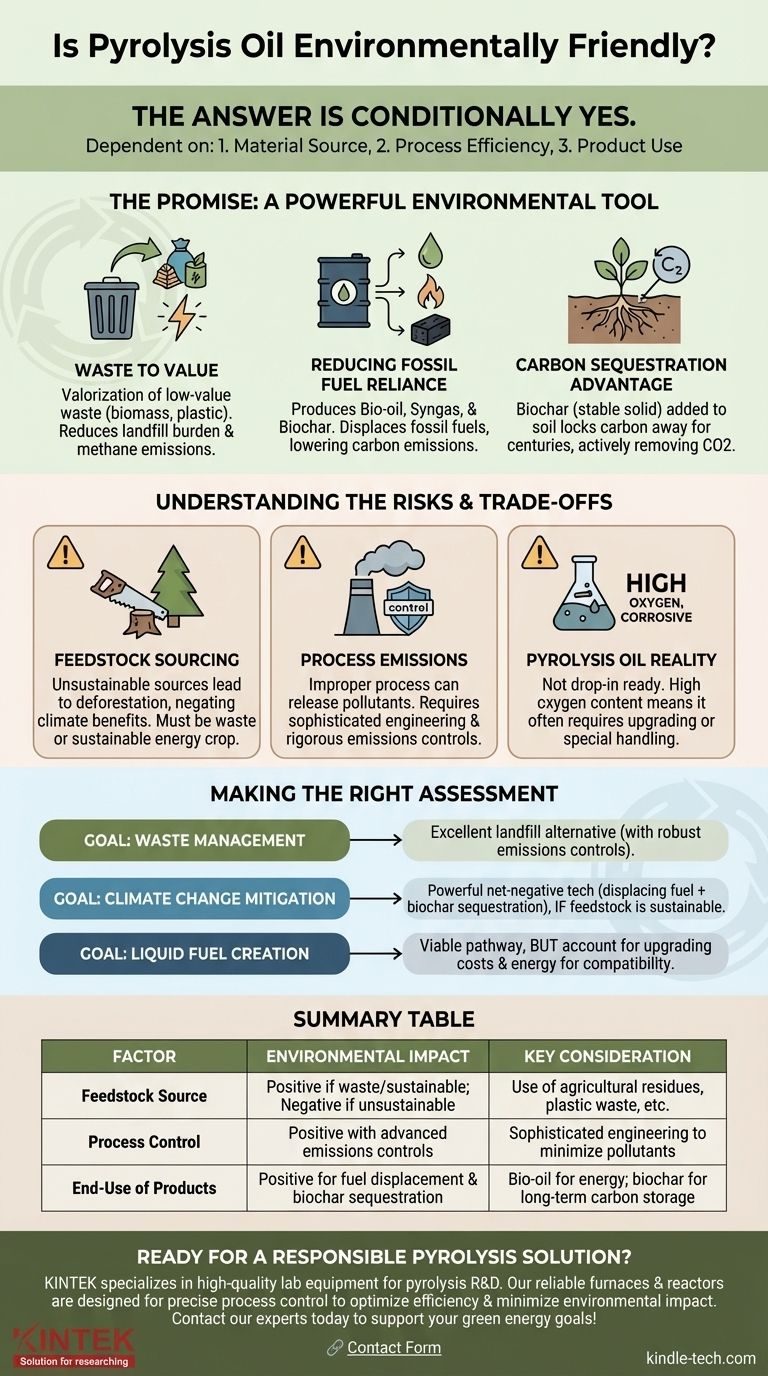

The answer is conditionally yes. The environmental friendliness of pyrolysis oil depends entirely on three factors: the source of the material being processed, the control and efficiency of the pyrolysis process itself, and how the resulting products are used. When managed correctly, it represents a significant environmental benefit over fossil fuels; when managed poorly, it can create its own set of environmental problems.

Pyrolysis is not inherently "good" or "bad" for the environment. It is a powerful conversion technology whose impact is determined by human choices. Its potential to reduce waste and sequester carbon is immense, but realizing that potential requires a responsible, whole-system approach.

The Promise: Why Pyrolysis Is a Powerful Environmental Tool

Pyrolysis is the process of heating organic material, such as biomass or plastic waste, at high temperatures in an oxygen-free environment. This thermal decomposition creates valuable products instead of just burning the material for heat.

From Waste to Value

The process provides a powerful method for valorization—turning low-value waste streams into high-value products. This includes agricultural residues, wood processing waste, and even municipal solid waste that would otherwise end up in a landfill.

By converting this waste, pyrolysis reduces landfill burden and the associated methane emissions, which are a potent greenhouse gas.

Reducing Reliance on Fossil Fuels

Pyrolysis produces three main products: bio-oil (a liquid fuel), syngas (a combustible gas), and biochar (a solid, charcoal-like substance).

The bio-oil and syngas can be used to generate energy, directly displacing the need for fossil fuels like natural gas or petroleum. This reduces the pollution and carbon emissions associated with extracting and burning those fuels.

The Carbon Sequestration Advantage

The most significant environmental benefit often comes from biochar. This stable, carbon-rich solid can be added to soil.

Unlike the carbon in the original biomass, which would decompose and return to the atmosphere as CO2, the carbon in biochar is locked away for hundreds or even thousands of years. This process of carbon sequestration actively removes carbon from the atmospheric cycle, making it a key tool in climate change mitigation.

Understanding the Trade-offs and Risks

The benefits of pyrolysis are compelling, but they are not guaranteed. Several critical factors can undermine its environmental credentials.

The Critical Role of Feedstock Sourcing

The single most important factor is the feedstock, or the raw material being processed. If pyrolysis relies on unsustainably harvested biomass, it can lead to deforestation and habitat destruction, completely negating any climate benefits.

True environmental friendliness is only achieved when the feedstock is a genuine waste product or a sustainably grown energy crop.

The Challenge of Process Emissions

The pyrolysis process itself can produce harmful emissions if not properly designed and operated. High temperatures in the furnace can release pollutants that impact local air quality.

Minimizing this impact requires sophisticated engineering, rigorous operational controls, and consistent maintenance to capture and treat any potential emissions before they are released.

The Reality of Pyrolysis Oil

Pyrolysis oil, often called bio-oil, is not a direct drop-in replacement for petroleum products. It has a high oxygen content, which makes it more corrosive, less stable, and immiscible with conventional fuels.

While it is a valuable energy source, its chemical properties mean it often requires further upgrading or must be used in specially designed engines or boilers. Ignoring these properties can lead to operational and handling challenges.

Making the Right Assessment for Your Goal

To determine if pyrolysis is an environmentally friendly choice, you must evaluate it against your specific objective.

- If your primary focus is waste management: Pyrolysis is an excellent alternative to landfilling for organic or plastic waste, provided the facility has robust emissions controls.

- If your primary focus is climate change mitigation: The combination of displacing fossil fuels and creating biochar for sequestration makes pyrolysis a powerful net-negative emissions technology, but only if the feedstock is from a verified waste or sustainable source.

- If your primary focus is creating liquid fuel: Pyrolysis is a viable pathway, but you must account for the costs and energy needed to upgrade the bio-oil for compatibility with existing infrastructure.

Ultimately, the environmental value of pyrolysis is a direct result of responsible and informed decision-making across its entire lifecycle.

Summary Table:

| Factor | Environmental Impact | Key Consideration |

|---|---|---|

| Feedstock Source | Positive if waste/sustainable; Negative if unsustainable | Use of agricultural residues, plastic waste, etc. |

| Process Control | Positive with advanced emissions controls | Sophisticated engineering to minimize pollutants |

| End-Use of Products | Positive for fuel displacement & biochar sequestration | Bio-oil for energy; biochar for long-term carbon storage |

Ready to implement a responsible pyrolysis solution in your lab?

At KINTEK, we specialize in high-quality lab equipment for pyrolysis research and development. Our reliable furnaces and reactors are designed for precise process control, helping you optimize conditions for maximum efficiency and minimal environmental impact. Whether you're exploring waste valorization, biochar production, or fuel upgrading, KINTEK provides the tools you need to make your pyrolysis projects a sustainable success.

Contact our experts today to discuss how our equipment can support your green energy goals!

Visual Guide

Related Products

- Electric Rotary Kiln Pyrolysis Furnace Plant Machine Calciner Small Rotary Kiln Rotating Furnace

- Electric Rotary Kiln Continuous Working Small Rotary Furnace Heating Pyrolysis Plant

- FS Electrochemical Hydrogen Fuel Cells for Diverse Applications

- Customizable CO2 Reduction Flow Cell for NRR ORR and CO2RR Research

- Customizable PEM Electrolysis Cells for Diverse Research Applications

People Also Ask

- What are the negative effects of plastic pyrolysis? The Hidden Environmental and Health Risks

- What is the process of biomass fast pyrolysis? Turn Biomass into Bio-Oil in Seconds

- What is the byproduct of calcination? Uncovering the Gases Released in Thermal Decomposition

- What is the difference between pyrolysis and incomplete combustion? The Critical Role of Oxygen in Thermal Processes

- What is the future potential of pyrolysis and gasification? Unlocking Value from Waste

- What is calcined material? A Guide to High-Temperature Material Transformation

- What is pyrolysis advantages and disadvantages? Unlocking Waste-to-Value Potential

- What is the use of a rotary furnace? Achieve Uniform Heating and Mixing for Superior Results