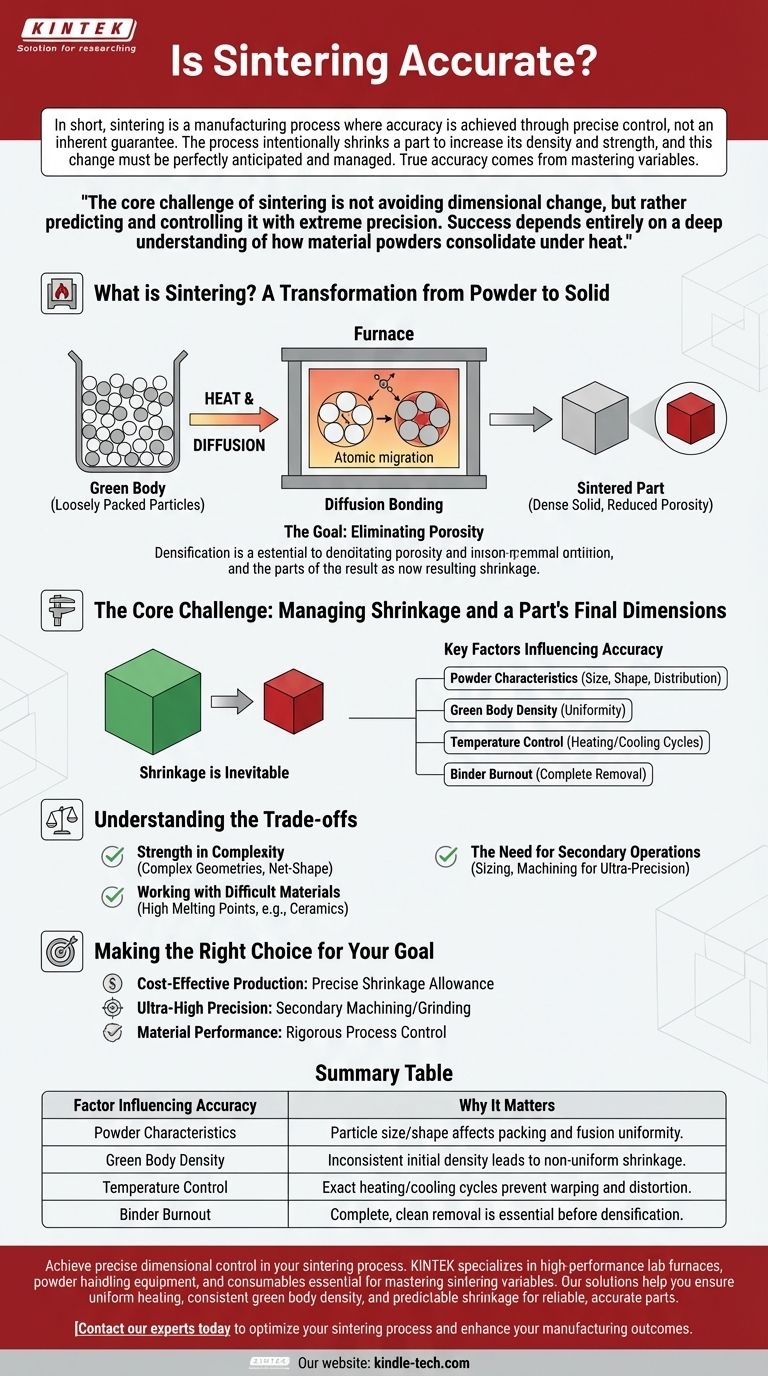

In short, sintering is a manufacturing process where accuracy is achieved through precise control, not an inherent guarantee. The process intentionally shrinks a part to increase its density and strength, and this change in dimension must be perfectly anticipated and managed. True accuracy in sintering comes from mastering the variables that govern this transformation.

The core challenge of sintering is not avoiding dimensional change, but rather predicting and controlling it with extreme precision. Success depends entirely on a deep understanding of how material powders consolidate under heat.

What is Sintering? A Transformation from Powder to Solid

Sintering is a thermal process that converts a loosely packed collection of particles, known as a "green body," into a dense, solid object. This is accomplished without melting the material outright.

The Role of Heat and Diffusion

A component formed from powder is heated in a furnace to a temperature below its melting point. At these high temperatures, the atoms at the contact points between individual particles become highly active.

This activity triggers diffusion bonding, where atoms migrate across the boundaries of the particles. The particles begin to fuse together, strengthening the material.

The Goal: Eliminating Porosity

As the particles bond, they pull closer, systematically eliminating the empty spaces or pores between them. This process, known as densification, is the primary source of the part's final strength and integrity.

The reduction in porosity directly causes the entire component to shrink in size.

The Core Challenge: Managing Shrinkage and a Part's Final Dimensions

The accuracy of a sintered part is entirely dependent on the predictability and uniformity of this shrinkage. Any variation can lead to a component that is out of tolerance.

Why Shrinkage is Inevitable

Shrinkage is a fundamental and necessary outcome of successful sintering. The volume once occupied by pores must be eliminated for the part to become dense and strong.

The amount of shrinkage is significant and must be calculated when designing the initial mold and the green body.

Key Factors Influencing Accuracy

Several variables must be tightly controlled to ensure the final part meets dimensional specifications:

- Powder Characteristics: The size, shape, and distribution of the initial powder particles directly impact how they pack and fuse.

- Green Body Density: The initial density of the pre-sintered part must be uniform. Any inconsistencies will lead to non-uniform shrinkage.

- Temperature Control: The heating rate, peak temperature, and cooling cycle must be exact. Uneven heating can cause warping and distortion.

- Binder Burnout: Binders used to hold the green body together must be burned off completely and cleanly at lower temperatures before densification begins.

Understanding the Trade-offs

Sintering is chosen for specific reasons, and its accuracy challenges are weighed against its significant manufacturing advantages.

Strength in Complexity

Sintering excels at producing geometrically complex, net-shape or near-net-shape parts that would be difficult or prohibitively expensive to create with traditional machining.

Working with Difficult Materials

The process is essential for materials with extremely high melting points, such as ceramics and certain refractory metals. For these materials, melting and casting is often not a viable option.

The Need for Secondary Operations

For applications requiring the highest levels of precision, sintered parts often undergo secondary operations. Calibrating, sizing, or light machining can be used to achieve final tolerances that the sintering process alone cannot guarantee.

Making the Right Choice for Your Goal

Achieving accuracy with sintering requires aligning the process capabilities with your component's specific requirements.

- If your primary focus is cost-effective production of complex parts: Design the component and tooling with a precise shrinkage allowance to leverage sintering's ability to create near-net shapes.

- If your primary focus is ultra-high precision: Plan to use sintering to efficiently create a near-net shape, but budget for secondary machining or grinding to achieve the final, tight tolerances.

- If your primary focus is material performance with hard-to-work materials: Sintering is your best, and sometimes only, option; invest heavily in rigorous process control to get as close to the desired accuracy as possible.

By viewing sintering as a controlled transformation, you can effectively harness its power for your specific manufacturing needs.

Summary Table:

| Factor Influencing Accuracy | Why It Matters |

|---|---|

| Powder Characteristics | Particle size/shape affects packing and fusion uniformity. |

| Green Body Density | Inconsistent initial density leads to non-uniform shrinkage. |

| Temperature Control | Exact heating/cooling cycles prevent warping and distortion. |

| Binder Burnout | Complete, clean removal is essential before densification. |

Achieve precise dimensional control in your sintering process. KINTEK specializes in high-performance lab furnaces, powder handling equipment, and consumables essential for mastering sintering variables. Our solutions help you ensure uniform heating, consistent green body density, and predictable shrinkage for reliable, accurate parts. Contact our experts today to optimize your sintering process and enhance your manufacturing outcomes.

Visual Guide

Related Products

- Dental Porcelain Zirconia Sintering Ceramic Furnace Chairside with Transformer

- Vacuum Dental Porcelain Sintering Furnace

- Vacuum Heat Treat and Molybdenum Wire Sintering Furnace for Vacuum Sintering

- Vacuum Heat Treat and Sintering Furnace with 9MPa Air Pressure

- Spark Plasma Sintering Furnace SPS Furnace

People Also Ask

- How energy-intensive are ULT freezers and what are their operating costs? Discover the True Cost of Ultra-Low Temperature Storage

- What are the limitations of diamonds? Beyond the Myth of Perfection

- What is the pulsed DC sputtering technique? A Stable Method for Depositing Insulating Films

- What is the primary purpose of using high-mesh SiC grinding paper? Optimize Surface Prep for Diffusion Bonding

- What advantages does a vacuum drying oven offer over a conventional drying oven? Enhance SCWO Research Accuracy

- How do precision stirring and temperature control systems influence catalyst production? Optimize Pd/NbOPO4/SBA-15

- What temperature do you heat treat a furnace? It's All About Your Material and Goal

- What material is resistant to extreme heat? Match the Right Material to Your Extreme Application