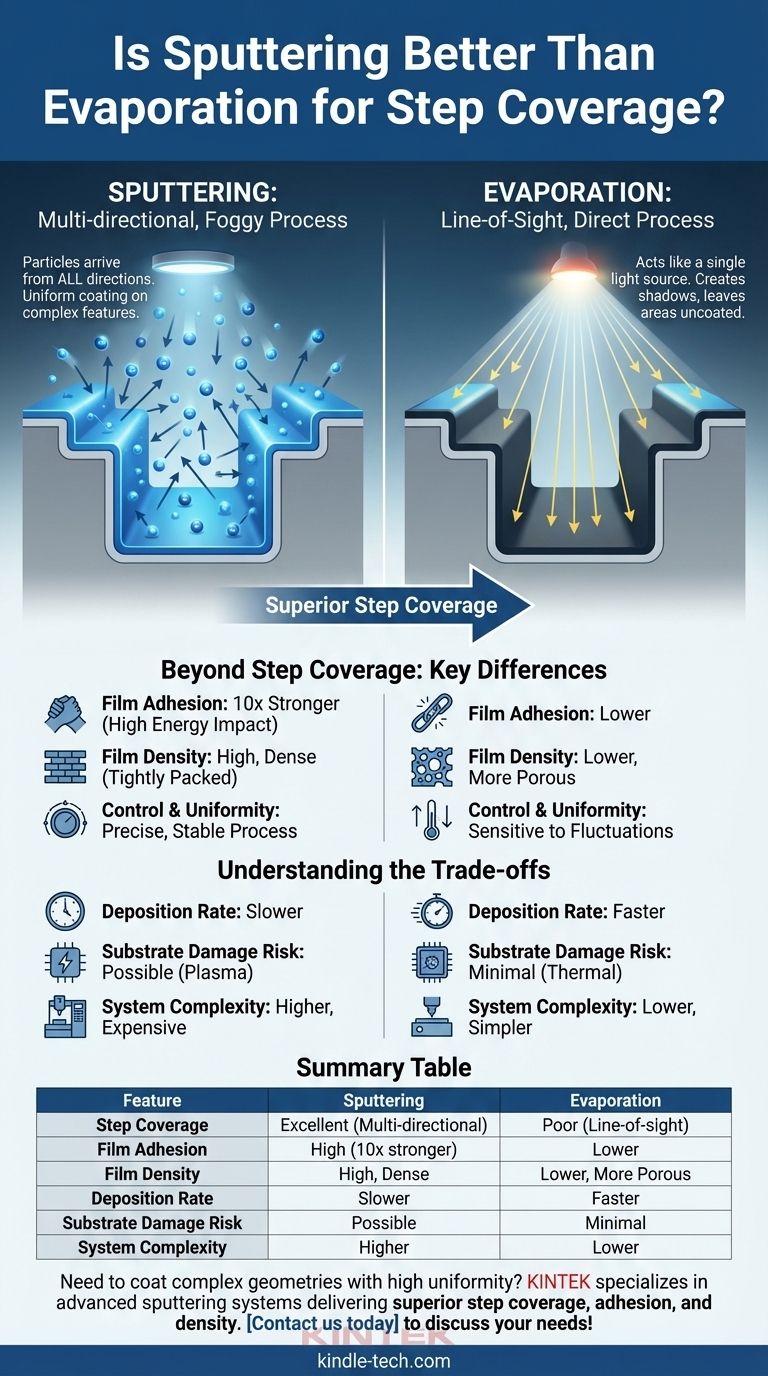

In short, yes. Sputtering provides demonstrably better step coverage than thermal or e-beam evaporation. The fundamental reason lies in the nature of the deposition: sputtering is a more diffuse, multi-directional process, whereas evaporation is a direct line-of-sight process that creates "shadows" on complex surfaces.

The core difference is how particles travel to your substrate. Evaporation acts like a single light source, leaving areas in shadow uncoated. Sputtering acts like a foggy day, where particles arrive from all directions, ensuring a much more uniform coating over complex features.

The Fundamental Difference: Particle Trajectory

To understand why sputtering excels at step coverage, we must first visualize how each process delivers material to the substrate. The method of particle transport is the single most important factor.

Evaporation: A Line-of-Sight Process

In thermal or e-beam evaporation, a source material is heated in a high vacuum until it vaporizes. These vaporized atoms travel in straight lines until they hit a surface and condense.

This direct, line-of-sight path is highly directional. For a flat substrate, this can be fine. But for a substrate with features like trenches or vias, the top surfaces receive the full deposition while the vertical sidewalls receive very little, if any, material. This leads to thin, non-uniform, or even discontinuous films on the sidewalls—a classic example of poor step coverage.

Sputtering: A Plasma-Driven Process

Sputtering operates on a completely different principle. An inert gas, typically Argon, is introduced into the vacuum chamber and ionized to create a plasma. These high-energy ions are accelerated into a target made of the desired coating material, physically knocking atoms off the target surface.

These sputtered atoms travel through the low-pressure gas environment, colliding with gas atoms along the way. This scattering randomizes their trajectory. As a result, atoms arrive at the substrate from a wide range of angles, not just a single direction. This multi-directional arrival is what allows sputtering to effectively coat the sidewalls and bottoms of trenches, creating a significantly more uniform film.

Beyond Step Coverage: Other Key Differences

While step coverage is a critical parameter for many applications, it's part of a larger picture of film quality. Sputtering generally produces films with superior mechanical and physical properties.

Film Adhesion and Density

The particles in a sputtering process arrive at the substrate with much higher kinetic energy than evaporated particles. This high energy results in two key benefits.

First, it creates significantly better film adhesion—often 10 times stronger than evaporated films. The energetic atoms can slightly implant into the substrate surface, forming a much stronger bond.

Second, it produces harder, denser films. The added energy helps atoms arrange themselves into a more tightly packed structure, reducing voids and improving the film's durability and barrier properties.

Control and Uniformity

Sputtering systems offer more precise control over film thickness and uniformity across the entire substrate. The process is more stable and repeatable compared to evaporation, where the deposition rate can be sensitive to fluctuations in source temperature.

Understanding the Trade-offs

Choosing sputtering is not without its compromises. The advantages in film quality come at a cost that must be considered for any application.

Deposition Rate

The most significant drawback of sputtering is its slower deposition rate. Evaporation can deposit material much more quickly, making it a more suitable choice for thick films or high-throughput manufacturing where supreme film quality is not the primary concern.

Potential for Substrate Damage

The high-energy plasma environment in sputtering can sometimes be a liability. Energetic particles can damage sensitive substrates or underlying electronic device layers. Evaporation, being a gentler, purely thermal process, avoids this risk of plasma-induced damage.

System Complexity

Sputtering systems are generally more complex and expensive than evaporation systems. They require sophisticated power supplies (DC or RF), gas handling systems, and more robust vacuum technology to maintain the plasma.

Making the Right Choice for Your Application

Your decision must be guided by the specific requirements of the film you are creating.

- If your primary focus is coating complex topographies with high fidelity: Sputtering is the definitive choice for its superior, non-directional step coverage.

- If your primary focus is film durability, density, and adhesion: Sputtering's high-energy process delivers mechanically superior films that are essential for demanding applications.

- If your primary focus is rapid deposition of a simple film on a flat surface: Evaporation offers a significant advantage in speed and cost-effectiveness.

- If you are working with extremely sensitive substrates: The gentle nature of thermal evaporation may be necessary to avoid plasma-induced damage.

Ultimately, your choice requires balancing the superior film quality and topographical coverage of sputtering against the speed and simplicity of evaporation.

Summary Table:

| Feature | Sputtering | Evaporation |

|---|---|---|

| Step Coverage | Excellent (Multi-directional) | Poor (Line-of-sight) |

| Film Adhesion | High (10x stronger) | Lower |

| Film Density | High, Dense | Lower, More Porous |

| Deposition Rate | Slower | Faster |

| Substrate Damage Risk | Possible (Plasma-induced) | Minimal |

| System Complexity | Higher | Lower |

Need to coat complex geometries with high uniformity? KINTEK specializes in advanced sputtering systems that deliver superior step coverage, excellent film adhesion, and dense, durable coatings for your most demanding laboratory applications. Let our experts help you choose the right deposition technology for your project. Contact us today to discuss your specific needs!

Visual Guide

Related Products

- RF PECVD System Radio Frequency Plasma-Enhanced Chemical Vapor Deposition RF PECVD

- Inclined Rotary Plasma Enhanced Chemical Vapor Deposition PECVD Equipment Tube Furnace Machine

- Chemical Vapor Deposition CVD Equipment System Chamber Slide PECVD Tube Furnace with Liquid Gasifier PECVD Machine

- Microwave Plasma Chemical Vapor Deposition MPCVD Machine System Reactor for Lab and Diamond Growth

- Customer Made Versatile CVD Tube Furnace Chemical Vapor Deposition Chamber System Equipment

People Also Ask

- Why does PECVD commonly use RF power input? For Precise Low-Temperature Thin Film Deposition

- What are the advantages of PECVD? Enable Low-Temperature, High-Quality Thin-Film Deposition

- What is an example of PECVD? RF-PECVD for High-Quality Thin Film Deposition

- What are the advantages of plasma enhanced CVD? Enable Low-Temperature, High-Quality Thin Film Deposition

- What is plasma enhanced? A Guide to Low-Temperature, High-Precision Manufacturing