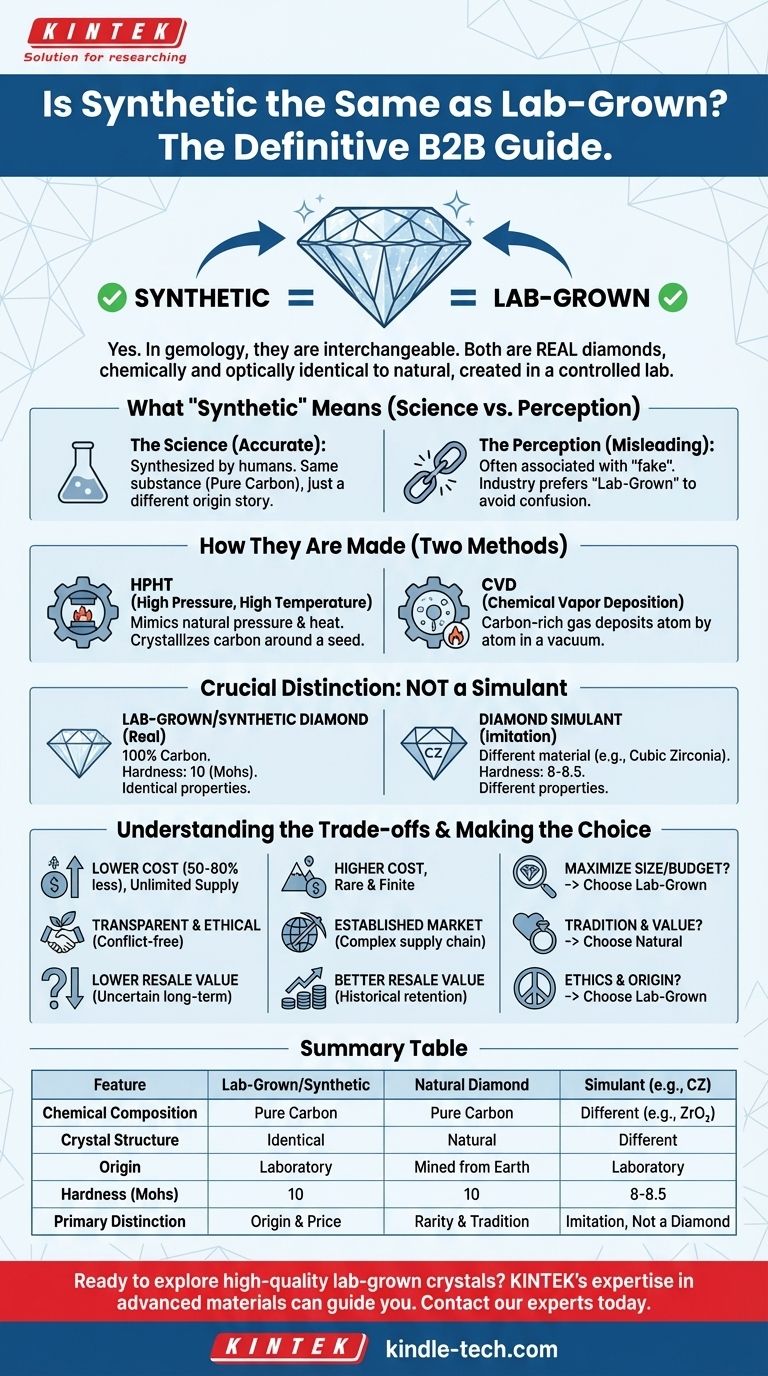

In the world of gemology, the terms are interchangeable. Yes, a synthetic diamond is the exact same thing as a lab-grown diamond. Both terms, along with others like "man-made" or "cultured," describe a diamond that was created by humans in a controlled laboratory setting rather than being mined from the earth. They are physically, chemically, and optically identical to a natural diamond.

The core confusion arises from the word "synthetic," which many people associate with "fake." In this technical context, synthetic simply means it was synthesized by humans. Both lab-grown and synthetic diamonds are real diamonds, completely distinct from imitation stones like cubic zirconia.

What Does "Synthetic" Actually Mean?

The term "synthetic" can be misleading, but in chemistry and material science, it has a precise meaning. It refers to a substance that has been formed through a human-controlled process of synthesis.

A Matter of Origin, Not Substance

A synthetic diamond is not a "fake" diamond. It is simply a diamond with a different origin story. It has the same crystal structure and is made of the same element—pure carbon—as a diamond formed deep within the Earth's mantle.

The only true difference is the environment in which that crystal grew. One grew over billions of years under natural geologic pressure, while the other grew over a few weeks in a highly controlled lab environment.

The Two Growth Methods

Lab-grown diamonds are typically created using one of two sophisticated processes.

- HPHT (High Pressure, High Temperature): This method mimics the natural diamond-growing process. A small diamond "seed" is placed in a chamber with carbon and subjected to immense pressure and heat, causing the carbon to crystallize around the seed.

- CVD (Chemical Vapor Deposition): In this method, a diamond seed is placed in a vacuum chamber filled with carbon-rich gas. The gas is heated, causing carbon atoms to break away and deposit onto the diamond seed, growing the crystal layer by layer.

Why the Different Terminology?

If the terms mean the same thing, why does the industry use so many? The answer comes down to marketing and public perception.

The "Synthetic" Connotation

The word "synthetic" often carries a negative connotation, suggesting something is an inferior or artificial substitute. This is a primary source of confusion for buyers, who may incorrectly lump synthetic diamonds in with simulants.

Distinguishing from Simulants

It is critical to distinguish a lab-grown (synthetic) diamond from a diamond simulant.

- Lab-Grown/Synthetic Diamond: Is a real diamond. It is 100% carbon and has a hardness of 10 on the Mohs scale.

- Diamond Simulant: Is a different material that looks like a diamond. Common examples are Cubic Zirconia (CZ) and moissanite. These have different chemical compositions, are less hard, and do not possess the same thermal properties.

The Rise of "Lab-Grown"

Because of the negative perception of "synthetic," the industry has largely adopted friendlier terms. "Lab-grown," "lab-created," "cultured," and "man-made" are now the preferred marketing terms because they accurately describe the origin without implying the stone is fake.

Understanding the Trade-offs

Choosing between a lab-grown and a natural diamond involves a clear set of trade-offs. Neither is inherently "better," but one may be better suited to your specific goals.

Cost vs. Rarity

The most significant difference is price. A lab-grown diamond can be 50-80% less expensive than a natural diamond of the same size and quality. This is because their supply is not finite; they can be created on demand. Natural diamonds derive much of their value from their geological rarity.

Resale Value

Natural diamonds have a long-established secondary market and tend to retain a percentage of their value over time. The long-term resale value of lab-grown diamonds is less certain and currently much lower, as the technology to produce them continues to advance and reduce costs.

Traceability and Ethics

Lab-grown diamonds offer a perfectly transparent chain of custody. You know exactly where and how your diamond was made, completely avoiding any concerns related to conflict mining or environmental impact.

Making the Right Choice for Your Goal

Ultimately, the terminology is less important than understanding the product. Once you know that "synthetic" and "lab-grown" mean the same real diamond, you can make a decision based on your priorities.

- If your primary focus is maximizing carat size and quality for a given budget: A lab-grown diamond is the logical choice, offering a much larger and cleaner stone for the price.

- If your primary focus is traditional romance and long-term value retention: A natural diamond is the more suitable option due to its history, rarity, and established secondary market.

- If your primary focus is a guaranteed conflict-free and transparent origin: A lab-grown diamond provides complete peace of mind.

Understanding that these terms describe the origin, not the substance, empowers you to select the diamond that aligns perfectly with your personal values.

Summary Table:

| Feature | Lab-Grown/Synthetic Diamond | Natural Diamond | Diamond Simulant (e.g., CZ) |

|---|---|---|---|

| Chemical Composition | Pure Carbon | Pure Carbon | Different (e.g., ZrO₂) |

| Crystal Structure | Identical to Natural | Natural | Different |

| Origin | Laboratory | Mined from Earth | Laboratory |

| Hardness (Mohs Scale) | 10 | 10 | 8-8.5 (CZ) |

| Primary Distinction | Origin & Price | Rarity & Tradition | Imitation, Not a Diamond |

Ready to explore the perfect diamond for your needs? Whether you're a jeweler seeking high-quality, ethically sourced stones or a researcher requiring precise lab-grown materials, KINTEK's expertise in advanced materials can guide you. We specialize in the technology behind high-quality lab-grown crystals. Contact our experts today to discuss how we can support your specific requirements with reliable, high-performance solutions.

Visual Guide

Related Products

- HFCVD Machine System Equipment for Drawing Die Nano-Diamond Coating

- CVD Diamond Cutting Tool Blanks for Precision Machining

- CVD Diamond Domes for Industrial and Scientific Applications

- 915MHz MPCVD Diamond Machine Microwave Plasma Chemical Vapor Deposition System Reactor

- Laboratory Sterilizer Lab Autoclave Vertical Pressure Steam Sterilizer for Liquid Crystal Display Automatic Type

People Also Ask

- What are the advantages of using HFCVD for BDD electrodes? Scaling Industrial Diamond Production Efficiently

- How does PACVD equipment improve DLC coatings? Unlock Low Friction and High Heat Resistance

- How are reactants introduced into the reaction chamber during a CVD process? Mastering Precursor Delivery Systems

- What is the specific function of the metal filament in HF-CVD? Key Roles in Diamond Growth

- What is the role of the HF-CVD system in preparing BDD electrodes? Scalable Solutions for Boron-Doped Diamond Production