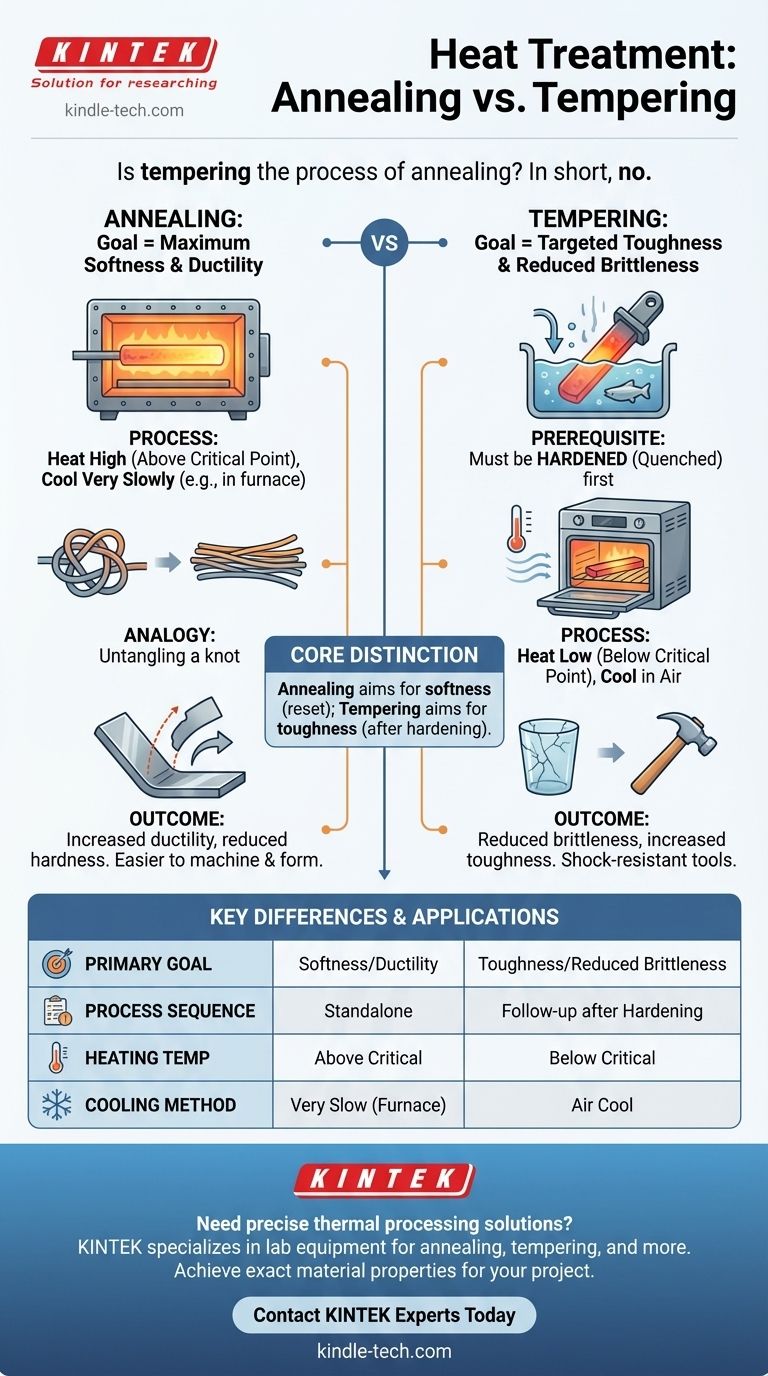

In short, no. Tempering and annealing are two distinct and fundamentally different heat treatment processes. While both involve heating and cooling metal to change its properties, their goals and methods are nearly opposite. Annealing is used to make a metal as soft and ductile as possible, whereas tempering is performed after a hardening process to reduce brittleness and increase toughness.

The core distinction is one of intent: annealing aims for maximum softness by heating a metal to a high temperature and cooling it slowly. Tempering aims for targeted toughness by heating a hardened metal to a much lower temperature to relieve brittleness.

What is Annealing? The Goal of Maximum Softness

Annealing is a foundational heat treatment process designed to "reset" a metal's internal structure, making it more uniform, softer, and easier to work with.

The Process: Heat High, Cool Slow

Annealing involves heating a material, such as steel, to a temperature above its upper critical or recrystallization point. It is held at this temperature long enough for the internal crystalline structure (grain) to fully reform, and then it is cooled very slowly, often by leaving it inside the insulated furnace to cool overnight.

The Outcome: Increased Ductility and Reduced Hardness

This slow cooling process removes internal stresses and creates a coarse grain structure. The result is a metal with its hardness significantly reduced and its ductility (the ability to be bent, stretched, or shaped without fracturing) greatly increased.

A Practical Analogy: Untangling a Knot

Imagine the internal structure of a stressed piece of metal is like a tangled, knotted rope. Annealing is the process of gently warming and slowly untangling that rope until all the fibers lay straight and parallel, making it flexible and easy to handle again.

What is Tempering? The Goal of Targeted Toughness

Tempering is a secondary process that is never performed on its own. It is always the second step in a two-part heat treatment used to create hard, durable, and shock-resistant parts.

A Critical Prerequisite: Hardening

Tempering is only ever performed on a metal that has first been hardened. The hardening process involves heating steel to a high temperature and then cooling it rapidly (quenching) in a medium like water or oil. This traps the carbon in a brittle, needle-like structure called martensite, making the steel extremely hard but also fragile, like glass.

The Process: Heat Low, Cool in Air

After quenching, the brittle steel is reheated to a much lower temperature—well below its critical point. The exact temperature is carefully controlled, as it determines the final balance of hardness and toughness. After being held at this temperature, the part is typically cooled in still air.

The Outcome: Reduced Brittleness, Increased Toughness

This reheating process allows some carbon to precipitate out of the martensite structure, relieving the intense internal stresses from quenching. Tempering sacrifices a small amount of hardness to gain a significant increase in toughness, which is the ability to absorb energy and deform without fracturing.

Understanding the Key Differences

The confusion between annealing and tempering often arises because both use heat. However, their opposing goals dictate every step of their respective processes.

Goal: Softness vs. Toughness

The primary goal of annealing is to induce maximum softness and ductility. The primary goal of tempering is to develop toughness in an already hardened part, creating a functional balance between hardness and brittleness.

Temperature: Above vs. Below Critical Point

Annealing requires heating the metal above its upper critical temperature to fully transform its crystal structure. Tempering is always performed at a much lower temperature, below the critical point.

Sequence: Standalone vs. Follow-up Process

Annealing is a standalone process that can be performed on metal in various states. Tempering is exclusively a follow-up step that is meaningless without first performing a hardening quench.

Making the Right Choice for Your Goal

Understanding the distinct purpose of each process is critical for achieving the desired material properties in any project.

- If your primary focus is to make metal easy to machine, bend, or form: Use annealing to achieve maximum softness and ductility.

- If your primary focus is to create a durable, shock-resistant tool like a spring, chisel, or axe head: Use a hardening process followed by tempering to achieve a tough, wear-resistant final product.

- If your primary focus is to simply remove stress from a welded part to prevent cracking: Use a specific type of annealing called stress relieving, which uses lower temperatures than a full anneal.

Ultimately, choosing the right heat treatment is about defining your end goal and applying the correct process to achieve it.

Summary Table:

| Feature | Annealing | Tempering |

|---|---|---|

| Primary Goal | Achieve maximum softness and ductility | Increase toughness and reduce brittleness |

| Process Sequence | Standalone process | Follow-up process after hardening/quenching |

| Heating Temperature | Heated above the critical temperature | Heated below the critical temperature |

| Cooling Method | Very slow cooling (e.g., in the furnace) | Cooled in air |

| Ideal For | Making metal easy to machine, bend, or form | Creating durable, shock-resistant tools and parts |

Need to apply the right heat treatment process to your materials? KINTEK specializes in the precise lab equipment and consumables you need for annealing, tempering, and other critical thermal processes. Our expertise ensures you achieve the exact material properties—whether it's maximum softness or superior toughness—required for your project's success. Contact our experts today to discuss your laboratory's specific needs and discover the right solution for you.

Visual Guide

Related Products

- Vacuum Heat Treat Furnace and Levitation Induction Melting Furnace

- Vacuum Heat Treat Sintering Brazing Furnace

- Molybdenum Vacuum Heat Treat Furnace

- Vacuum Heat Treat and Molybdenum Wire Sintering Furnace for Vacuum Sintering

- 1200℃ Controlled Atmosphere Furnace Nitrogen Inert Atmosphere Furnace

People Also Ask

- Role of Muffle Furnaces in CeO2 Synthesis: Achieve Precise Crystalline Transformation

- Which material is used in a muffle furnace? The Key to High-Temperature Performance and Purity

- What are the precautions of muffle furnace? Essential Safety Protocols for Your Lab

- What is the difference between firing and sintering? Master the Thermal Process for Stronger Materials

- Which of the following are the important temperature controls used in sintering furnace? Mastering Precise Thermal Profiles for Superior Materials

- Why must LAGP glass melts be immediately placed in a heating furnace for annealing at 500°C after quenching?

- What are the applications of muffle furnace in pharmaceutical industry? Ensure Drug Purity and Quality

- What is the function of high-temperature thermal annealing in a muffle furnace? Optimize CeO2 Microsphere Synthesis